Analyzing the Key Trends in the India Abrasives Industry

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The India abrasives industry plays a critical role in the country’s manufacturing, construction, and automotive sectors. From grinding, cutting, polishing, to finishing applications, abrasives are the unsung backbone of precision engineering and product quality enhancement.

As India's industrial and infrastructure landscape continues to evolve, the abrasives market is undergoing a significant transformation—driven by rising demand from end-user industries, technological advancements, and supportive government policies under the “Make in India” initiative.

According to the India Abrasives Market Report, the market is poised for steady growth through 2028, with both bonded and coated abrasives gaining traction across manufacturing hubs in Maharashtra, Tamil Nadu, and Gujarat.

In this blog, we explore the key trends shaping the growth and innovation in the abrasives ecosystem in India.

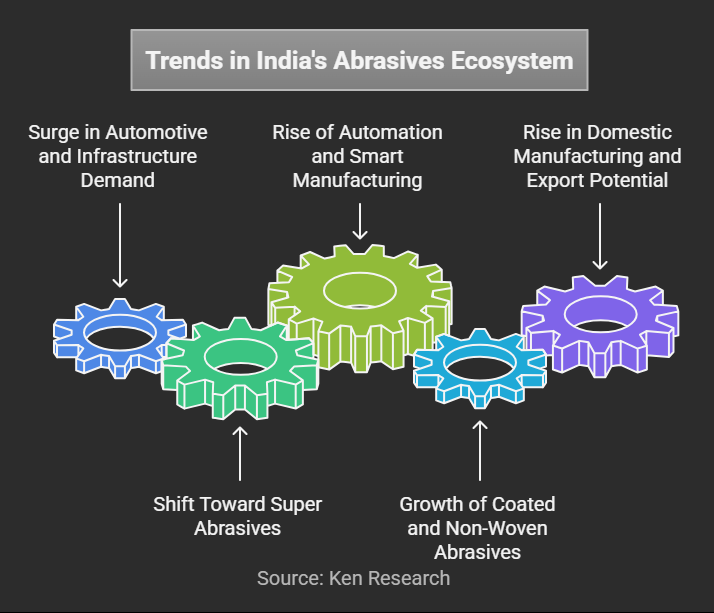

Surge in Automotive and Infrastructure Demand

The rebound of the automotive sector post-pandemic has significantly boosted the demand for abrasives used in body panel sanding, gear polishing, and engine part finishing. With electric vehicles (EVs) also gaining ground, precision-grade abrasives are needed for battery component production and lightweight structural parts.

Additionally, the Indian government’s push for infrastructure development—via projects such as Gati Shakti and smart cities initiatives—has led to increased usage of abrasives in construction and metal fabrication activities.

Key Insight: Abrasives are no longer limited to traditional uses—they’re becoming integral to new-age mobility and infrastructure.

Shift Toward Super Abrasives and High-Precision Applications

Industries such as aerospace, medical devices, and precision tool manufacturing are now demanding super abrasives—including cubic boron nitride (CBN) and synthetic diamonds—for tasks requiring high surface finishes and minimal material loss.

These materials offer better durability, higher heat resistance, and superior performance.

As Indian industries seek global export competitiveness, super abrasives are enabling manufacturers to meet tighter tolerances and better product standards.

Explore a similar evolution in consumer demand trends within this Asia Pacific Food and Beverage Market Analysis, where high-quality expectations are reshaping product offerings.

Rise of Automation and Smart Manufacturing

With India making steady progress in Industry 4.0 adoption, there is increasing integration of automation, robotics, and IoT in grinding and finishing lines. This is pushing abrasive manufacturers to innovate:

- Development of abrasive tools compatible with CNC machines

- Digital control of grinding pressure and movement

- Predictive maintenance solutions based on wear analysis

Trend Impact: Abrasives are being redesigned for consistency and adaptability in smart manufacturing environments, especially across automotive and general engineering segments.

Growth of Coated and Non-Woven Abrasives

Coated abrasives like sandpaper and flap discs are increasingly used in furniture, metal fabrication, and consumer goods industries. Their flexibility and affordability make them suitable for both small-scale and industrial users.

Non-woven abrasives are gaining traction in surface preparation, rust removal, and finishing in stainless steel and aluminum processing.

The domestic market is seeing an influx of multi-material abrasive tools, combining performance with longer tool life.

Rise in Domestic Manufacturing and Export Potential

Under the PLI (Production Linked Incentive) schemes and increasing emphasis on import substitution, India is emerging as a regional hub for abrasive manufacturing.

- Local companies are expanding capacities and forming joint ventures with international players to bring in advanced technologies.

- The focus is on capturing market share in Southeast Asia, Middle East, and Africa for both raw abrasive grains and finished products.

- The strategic importance of building localized supply chains and export momentum is similar to what is observed in this regional market analysis, where regional growth corridors are being leveraged for scale.

Final Outlook: Precision Meets Performance

As Indian manufacturers move toward high-quality production and automation-driven efficiency, the abrasives industry will become even more essential. Whether it’s for shaping EV components or polishing architectural fixtures, abrasives will be the enablers of durability, aesthetics, and performance.

To explore segment-wise growth forecasts, competitive landscape, and procurement trends, access the full India Abrasives Market Report

For a snapshot version with actionable insights, download the Sample Report here

The Indian abrasives market is grinding toward growth—and it’s smoother, smarter, and more strategic than ever before. Are you ready to seize the momentum?

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.