Applications of Nitronic 50 Rod and Wire in Aerospace and Automotive Industries

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

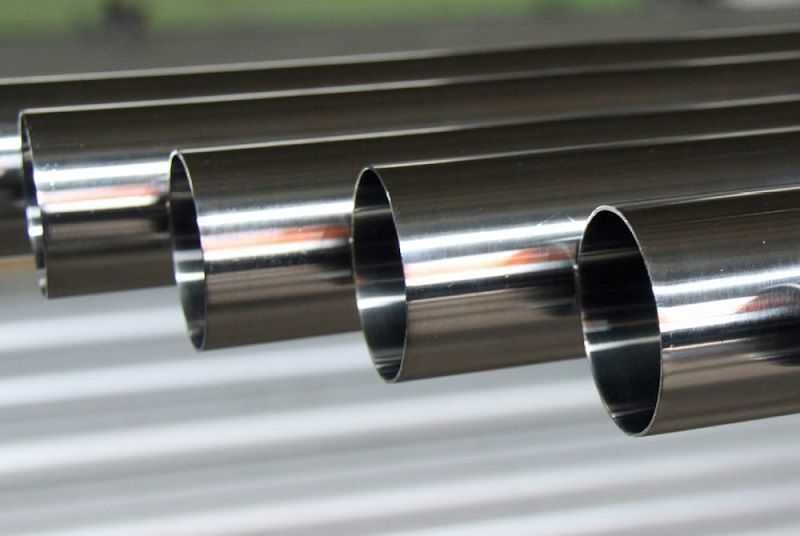

Nitronic 50 rod, bars, wire, wire mesh is widely used in industries that require high strength, corrosion resistance, and durability. The aerospace and automotive industries depend on advanced materials to ensure efficiency, safety, and performance. Nitronic 50 wire, wire mesh is one such material that meets these requirements due to its superior mechanical properties and ability to withstand extreme conditions. This blog explores the various applications of Nitronic 50 rod, bars, wire, wire mesh in aerospace and automotive industries.

Properties of Nitronic 50 for Aerospace and Automotive Applications

1. High Corrosion ResistanceThe aerospace and automotive industries often operate in environments that expose materials to moisture, chemicals, and extreme temperatures. Nitronic 50 wire, wire mesh provides exceptional corrosion resistance, making it ideal for parts exposed to harsh conditions. This ensures long-lasting performance, reducing maintenance and replacement costs.

2. Superior Strength and DurabilityCompared to standard stainless steel alloys, Nitronic 50 rod, bars, wire, wire mesh offers higher strength while maintaining good flexibility. This property is essential for aerospace and automotive applications where components must endure high stress and pressure.

3. Wear and Galling ResistanceOne major challenge in mechanical applications is wear and galling, which can lead to component failure. Nitronic 50 wire, wire mesh has excellent resistance to these issues, ensuring that moving parts remain functional even under constant friction.

4. Non-Magnetic BehaviorMany aerospace and automotive components require non-magnetic materials to prevent interference with sensitive electronic systems. Nitronic 50 rod, bars, wire, wire mesh remains non-magnetic even after cold working, making it ideal for applications where magnetic properties must be controlled.

5. High Temperature and Cryogenic PerformanceExtreme temperatures can significantly impact the performance of materials. Nitronic 50 wire, wire mesh maintains its mechanical properties in both high-temperature and cryogenic environments, making it useful in aerospace engines and automotive exhaust systems.

Applications of Nitronic 50 in Aerospace Industry

1. Structural ComponentsAerospace structures require materials that offer high strength and resistance to environmental factors. Nitronic 50 rod, bars, wire, wire mesh is used in aircraft frames, landing gear components, and support structures due to its ability to withstand high stress.

2. Fasteners and BoltsAircraft rely on fasteners and bolts that can endure high mechanical loads and resist corrosion. Nitronic 50 wire, wire mesh is used to manufacture high-strength fasteners that maintain their integrity under extreme conditions.

3. Engine and Exhaust SystemsAircraft engines and exhaust systems operate under extreme heat and pressure. Nitronic 50 wire, wire mesh is ideal for these applications due to its excellent heat resistance and mechanical stability.

4. Control Cables and SpringsAircraft control systems require durable cables and springs that resist wear and corrosion. Nitronic 50 wire, wire mesh is widely used in these components to ensure reliable performance over time.

Applications of Nitronic 50 in Automotive Industry

1. Exhaust and Turbocharger ComponentsAutomotive exhaust systems and turbochargers are exposed to high temperatures and corrosive gases. Nitronic 50 rod, bars, wire, wire mesh is used to manufacture these components, ensuring durability and improved performance.

2. Suspension and Chassis PartsVehicles require strong and flexible materials for suspension and chassis components. Nitronic 50 wire, wire mesh is used in critical parts that need to withstand road stress while maintaining lightweight properties.

3. Fasteners and SpringsJust like in aerospace applications, automotive fasteners and springs must endure high mechanical loads. Nitronic 50 wire, wire mesh is preferred for these components due to its wear resistance and long lifespan.

4. Electrical and Sensor SystemsModern vehicles rely on advanced electronic systems, which require materials with non-magnetic properties. Nitronic 50 rod, bars, wire, wire mesh is used in electronic shielding and sensor housings to prevent interference with signals.

Conclusion

The aerospace and automotive industries require materials that offer superior performance in demanding environments. Nitronic 50 rod, bars, wire, wire mesh provides excellent strength, corrosion resistance, and durability, making it a preferred choice for critical applications. Its ability to withstand extreme temperatures, resist wear, and maintain non-magnetic properties makes it invaluable in these industries. By using Nitronic 50 wire, wire mesh, manufacturers ensure high-quality, long-lasting components that enhance safety and efficiency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.