Carbon Fiber Reinforced Plastics Market Global Opportunities, Trends, Outlook & Forecast 2032

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The global Carbon Fiber Reinforced Plastics (CFRPs) Market is witnessing significant growth driven by increasing demand across aerospace, automotive, energy, construction, and sports industries. Renowned for their excellent strength-to-weight ratio, high stiffness, and resistance to fatigue and corrosion, CFRPs have become essential in applications that demand durability and lightweight performance.

In 2024, the global Carbon Fiber Reinforced Plastic Market was valued at approximately USD 18.92 billion and is projected to reach USD 20.72 billion by 2025. Looking ahead, the market is expected to grow robustly, reaching USD 38.2 billion by 2032. Under extended projections, it is forecasted to hit USD 32.8 billion by 2032, registering a compound annual growth rate (CAGR) of around 9.1% between 2025 and 2032.

Key Market Drivers

Rising Demand for Lightweight Materials

The push for lightweighting across transportation sectors is one of the strongest drivers of CFRP market growth. In the aerospace and automotive industries, CFRPs are used to reduce component weight, which in turn improves fuel efficiency, reduces emissions, and enhances speed and performance. In electric vehicles, lighter structures allow for longer battery range and better performance, while in aircraft, CFRPs help reduce fuel consumption and increase payload efficiency.

Advanced Properties and Versatility

CFRPs offer exceptional mechanical properties, including high tensile strength, chemical resistance, low thermal expansion, and dimensional stability. These materials are ideal for critical structural applications and are now used in aerospace fuselages, automotive body panels, sports equipment, and even medical components.

Growth in Renewable Energy Sector

Wind turbine manufacturers are turning to CFRPs for blade production, particularly for longer, more efficient blades. The material’s strength and durability ensure better energy generation performance and reduce long-term maintenance costs, which is vital in remote wind farm locations.

Infrastructure and Civil Engineering Applications

CFRPs are increasingly being used for retrofitting aging infrastructure, such as bridges and buildings. Compared to traditional materials like steel, CFRPs provide corrosion resistance and a long lifespan, with the added benefit of minimal structural weight addition.

List Of Key Market Players Profiled In The Report

Hexcel Corporation (U.S.)

TORAY INDUSTRIES, INC. (Japan)

SGL Carbon (Germany)

Mitsubishi Chemical Group Corporation. (Japan)

TEIJIN LIMITED. (Japan)

Market Segmentation

By Precursor Type

PAN-based Carbon Fiber: Dominates the market due to high performance and widespread availability.

Pitch-based and Rayon-based Carbon Fiber: Used in specialized applications where unique electrical or thermal properties are required.

By Resin Type

Thermosetting Resins: Including epoxy and phenolic resins, are widely used for their high strength and temperature resistance.

Thermoplastic Resins: Offer advantages like recyclability, faster processing times, and improved impact resistance, gaining traction in automotive applications.

By Product Form

Prepregs: Pre-impregnated fabrics with resin, widely used in aerospace and high-performance sports applications.

Molded Components: For automotive and industrial equipment.

Laminates and Woven Fabrics: Used in general manufacturing and infrastructure projects.

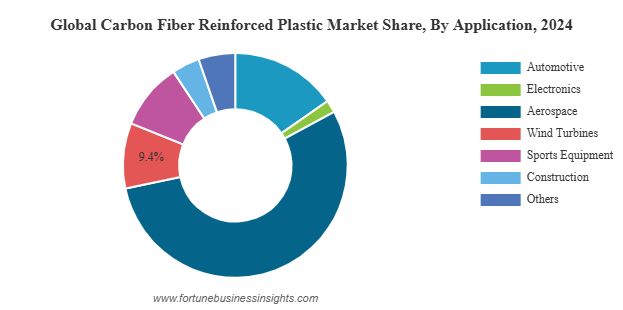

By Application

Aerospace & Defense: Leading segment due to strict structural performance needs.

Automotive: Increasing adoption in electric and luxury vehicles.

Wind Energy: High demand for lightweight, durable blades.

Construction: Used in retrofitting and reinforcement.

Sports & Leisure: Growing use in bicycles, golf clubs, and racquets.

Regional Insights

North America: A mature market led by aerospace and defense, with increasing adoption in electric vehicles and wind energy.

Europe: Driven by stringent environmental regulations, promoting lightweight automotive components and energy-efficient structures.

Asia Pacific: Expected to witness the fastest growth due to rapid industrialization in China, Japan, South Korea, and India. Government support for renewable energy projects and manufacturing expansions contribute significantly.

Latin America, Middle East & Africa: Emerging markets benefiting from infrastructure development and growing energy projects.

Read More : https://www.fortunebusinessinsights.com/carbon-fiber-reinforced-plastics-cfrps-market-110101

Market Trends

Technological Advancements

New manufacturing technologies such as automated fiber placement, tailored fiber placement, and 3D weaving techniques are revolutionizing the CFRP industry. These advancements improve material utilization, reduce production time, and lower costs.

Sustainability Focus

Sustainability remains a core trend. Companies are exploring ways to improve recyclability and reduce environmental impact. Thermoplastic CFRPs and improved fiber reclamation processes are being developed to enable a circular economy approach in composites.

Innovative Applications

With continuous R&D, CFRPs are finding new uses in medical devices, drones, satellites, robotics, and consumer electronics. Innovations in nanocomposite CFRPs using carbon nanotubes or graphene are also enhancing properties like conductivity and heat resistance.

Challenges in the CFRP Market

High Manufacturing Costs: The cost of raw materials and energy-intensive processing limits large-scale use in cost-sensitive sectors.

Complex Recycling Processes: While technically recyclable, the lack of standardized, cost-effective recycling methods poses a barrier.

Design and Engineering Complexity: Effective use of CFRPs requires specialized design and analysis, which increases development time and cost.

Regulatory Hurdles: Varying standards and certifications across industries and regions can slow down adoption.

Competitive Landscape

Leading companies in the CFRP market are investing in expanding their product portfolios, enhancing automation, and forming strategic partnerships. Some of the prominent names include:

Major carbon fiber manufacturers

Composite material developers

Aerospace and automotive suppliers with dedicated composite divisions

Key Industry Developments

March 2025: Hexcel and FIDAMC have partnered to advance composite materials for aerospace and industrial applications. Their collaboration focuses on developing innovative manufacturing processes to enhance lightweight, high performance composites. This partnership aims to improve efficiency and sustainability in composite production.

November 2024: Toray advanced composites expanded its thermoplastic composites portfolio by acquiring Gordon Plastics assets in Colorado. The new 47,000 sq.ft facility enhances R&D and scalable production of high-performance composite tapes for aerospace, sports, oil & gas, and industrial markets.

Future Outlook

The Carbon Fiber Reinforced Plastics market is set for strong growth over the next decade. With expanding applications across diverse industries, combined with ongoing innovation and increasing environmental consciousness, CFRPs are likely to become a mainstay material in both structural and performance-driven fields. The integration of sustainable production methods, automation, and recyclable composite technologies will play a crucial role in shaping the market’s trajectory through 2032 and beyond.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.