Circuit Breaker Lockout Devices: Essential Tools for Electrical Safety Compliance

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

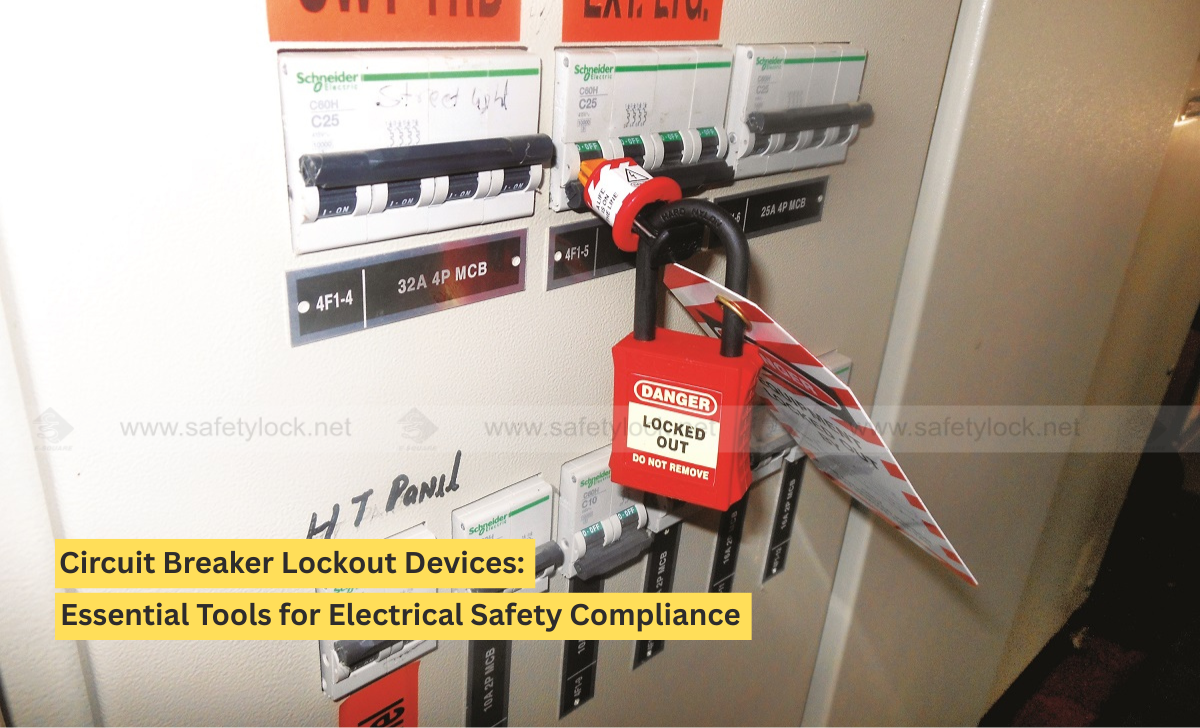

Electrical safety is a cornerstone of any workplace safety program, especially in environments where maintenance and servicing of energized equipment are routine. One of the most overlooked yet critical safety measures in such settings is the proper isolation of circuit breakers using lockout devices. Circuit breaker lockout devices are designed to prevent accidental re-energization during maintenance activities, protecting workers from electrical hazards and ensuring compliance with safety regulations such as OSHA (Occupational Safety and Health Administration) standards.

Understanding Circuit Breaker Lockout Devices

A circuit breaker lockout device is a safety mechanism that physically blocks access to the switch or toggle of a circuit breaker, thereby preventing it from being turned on while maintenance is underway. These devices are an essential component of a Lockout Tagout system, which is implemented to isolate hazardous energy sources during equipment servicing or repair.

There are several types of circuit breaker lockout devices designed to suit a variety of breaker styles, sizes, and applications. Pin type lockouts and miniature circuit breaker lockouts are commonly used for compact breakers with narrow toggles or pinholes. Clamp-on lockouts provide a secure fit for broader breaker switches, while motor protection circuit breaker lockouts are specifically designed for breakers that control industrial motors. These devices are typically secured with a padlock and tagged with a warning label, clearly indicating that equipment is under maintenance and must not be energized.

Why Circuit Breaker Lockouts are Critical for Safety?

Electrical currents pose severe risks such as electrocution, burns, arc flashes, and even fatalities. Many of these incidents occur when equipment is inadvertently energized during servicing. Circuit breaker lockout devices eliminate this risk by ensuring that breakers remain in the "OFF" position until all maintenance activities are completed and the lockout device is removed by authorized personnel.

In addition to safeguarding workers, these devices help enforce a systematic approach to energy control. Their use ensures that only trained and authorized individuals can access and operate electrical panels, reducing human error and enhancing operational discipline.

Compliance with OSHA and Other Standards

OSHA mandates the use of lockout tagout procedures for the control of hazardous energy (29 CFR 1910.147). This regulation outlines the employer's responsibility to implement and enforce energy control procedures, which include the proper use of lockout devices. Failure to comply can lead to serious penalties, both in terms of fines and worker safety.

Circuit breaker lockouts play a key role in meeting these compliance requirements. By using them consistently and correctly, employers demonstrate a proactive approach to workplace safety, thereby reducing liability and fostering a culture of accountability.

Types of Circuit Breaker Lockout Devices:

Choosing the right lockout device depends on the type of circuit breaker in use. Below are commonly used circuit breaker lockout types designed to suit a variety of electrical configurations:

• Pin Type Circuit Breaker Lockout - These devices insert directly into the breaker’s switch and are secured with a padlock, offering a compact and secure locking solution.

• Miniature Circuit Breaker Lockout - Specifically designed for small, compact breakers found in commercial or industrial electrical panels. They typically clip directly onto the breaker without requiring tools.

• Clamp-On Breaker Lockout - A versatile option that clamps over the breaker switch and tightens using a screw mechanism. Suitable for both single-pole and multi-pole breakers, offering a strong hold for a variety of applications.

• Motor Protection Circuit Breaker Lockout - These are built to fit over specialized circuit breakers used in motor control circuits. Their design ensures the breaker remains in the off position during equipment maintenance.

• Conventional Circuit Breaker Lockout - Designed for standard breakers found in most industrial and commercial setups. These lockouts are easy to install and compatible with a wide range of padlocks.

Each of these lockout types plays a crucial role in meeting the needs of different circuit configurations and ensuring effective energy isolation.

Conclusion

Circuit breaker lockout devices are not just devices; they are fundamental to maintaining electrical safety in any workplace. By physically preventing the accidental energization of electrical circuits, these devices protect workers, ensure compliance with regulatory standards, and support an organized and disciplined safety culture.

Investing in the right circuit breaker lockout solutions is an investment in worker safety and organizational integrity. As the saying goes, “Safety doesn’t happen by accident,” and with circuit breaker lockouts, you can make sure it never does.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.