Preserving Lives and Assets: The Art of Effective Lockout Tagout Implementation

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Efficient lockout tagout procedures can enhance your unit's productivity and efficiency. The process of implementing lockout tagout involves critical aspects related to safely de-energising machines or equipment.

In manufacturing industries and plants where heavy machinery is operated regularly, the need for its maintenance and clean-up is commonplace. Although safety procedures during the regular operation of machinery are well-known and widely discussed, precautionary measures during maintenance and repair are not completely enforced. During machine/equipment repair, maintenance, clean-up, servicing, or any other process, it is not enough to just shut off the equipment, a specific set of procedures needs to be implemented to make sure that no harm comes to the individual maintaining the machine or the equipment itself. This set of procedures is called Lockout Tagout.

Understanding Lockout Tagout (LOTO)

Lockout Tagout is a safety procedure designed to ensure that dangerous machines are properly shut off and cannot be restarted until maintenance work is complete. The primary objective of LOTO is to ensure that all sources of energy, including electrical, mechanical, hydraulic, pneumatic, chemical, thermal, or other forms, are isolated and rendered inoperative before any maintenance work begins. For that, the authorised employee must follow a set of written procedures to lock, tag and safeguard the machinery.

The process of implementing lockout tagout involves critical aspects related to safely de-energising machines or equipment. Following are the 10 crucial guidelines along which lockout tagout must be carried out and sustained.

1- Develop and Document Energy Control Procedures

The Lockout Tagout procedures begin with identifying all the hazardous sources of energy which can lead to unauthorised or accidental re-energisation. On basis of the survey conducted, a detailed document is developed, specifying methods of shutting down, releasing stored energy, locking and restarting the equipment.

2- Train Authorized Employees

A critical aspect of lockout tagout procedures is to train the relevant employees on how to properly implement the safety procedures. The authorised personnel must undergo thorough training as documented in the detailed lockout tagout manual, while all other employees (Affected and Others) must also be trained on lockout tagout to mitigate the risks during a maintenance procedure.

3- Prepare for Lockout Tagout

Before initiating the machinery lockout/tagout, authorised personnel must notify all affected employees about the planned maintenance or servicing and the application of energy control procedures. Accurate information regarding the maintenance schedule and any updates or changes should be communicated promptly to prevent unexpected equipment re-energization attempts.

4- Shut Down

The authorised employee should follow the standardised and documented procedure, such as using the correct power switch, lever and all main sources of energy to shut down the equipment as documented in the guidelines.

5- Isolation of Energy Sources

The next step is to isolate all hazardous energy sources as detailed in the document. This involves disconnecting power cables or closing valves to ensure complete energy isolation.

6- Lock and Tag Placement

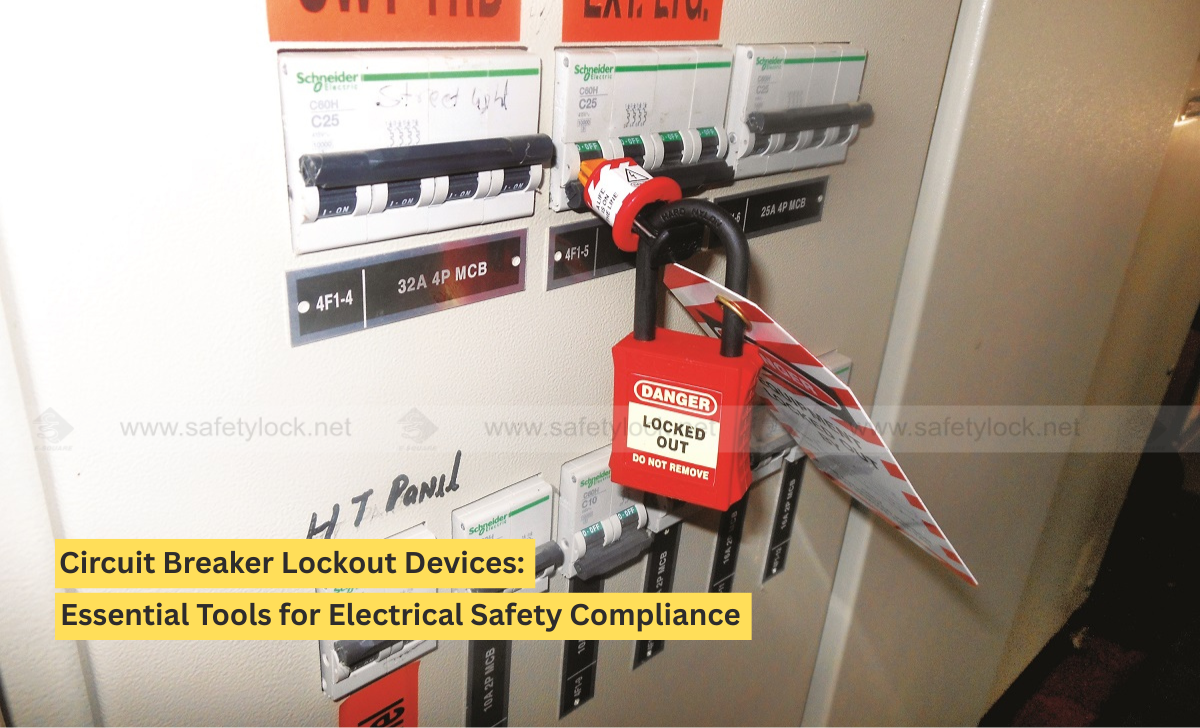

Once the equipment is isolated and shut off, the authorised employee must attach the relevant lockout device and a tag with his name and details. Each type of equipment has its own, specially designed lockout device like di-electric padlocks on electric breaker panels or valve covers on control valves are essential for preventing unauthorized equipment manipulation.

7- Stored Energy Release

Despite proper shutdown and lockout procedures, machinery may still pose safety risks due to residual stored energy. It is important to address the potential hazards such as spring tension, heated liquids, or venting gases to ensure a safe maintenance environment. The authorised employee must release the stored energies as well.

8- Energy Isolation Verification

The final step in ensuring complete lockout tagout implementation is to verify that the machinery has been isolated completely. A thorough inspection of the above-mentioned steps will confirm the isolation. Authorised employees should make use of the detailed procedures and various methods outlined in the LOTO program to verify zero energy state of the machine or equipment.

9- Equipment Re-energisation

Upon completion of maintenance, an authorised employee must confirm that all workers are informed of the planned re-energisation and are positioned safely. All tools and repair equipment should be removed, and the lockout tagout devices should only be removed by the individual who placed them, using the standardised re-energisation procedure of the equipment.

10- Procedure Update

The last and most critical aspect of having a lockout tagout procedure is regularly updating them on the documentation and periodic equipment inspections. It is considered best practice to review and update the lockout tagout procedures at least annually to ensure compliance with current safety standards and OSHA regulations.

The Importance of Effective LOTO Implementation

According to the Occupational Safety and Health Administration (OSHA), failure to control hazardous energy accounts for nearly 10% of serious accidents in many industries. Lockout Tagout stands as the ultimate barrier to preventing maintenance and repair injuries like electrocutions, burns, crushing injuries, amputations, and others. By meticulously following LOTO protocols, companies can significantly reduce the risk of workplace injuries and fatalities, ensuring that employees return home safely to their families each day.

In addition to human safety, the lockout tagout system also plays an important role in protecting valuable machine assets. Accidents involving heavy machinery can cause catastrophic damage, requiring costly repairs or even costly equipment replacement. Each incident can be prevented through the proper use of the LOTO leading to a great deal of savings for the company, reinforcing the financial importance of this security measure. Furthermore, the indirect benefits of the LOTO system extend to increased operational productivity and efficiency. Workplace incidents not only threaten worker safety but also disrupt production processes. After an accident, production is often halted to facilitate immediate treatment and subsequent investigations. Depending on the severity of the issue, this downtime can stretch from hours to days, significantly affecting both business operations and the bottom line.

A proactive technique for maintenance safety is much needed in today’s fast-paced world. Regulatory compliances, safety processes and enforced guidelines create a sense of safety and protection for both employees and employers.

To develop efficient lockout tagout procedures that enhance your unit's productivity and efficiency, E-Square is your No. 1 Energy Isolation Partner. Their experts will survey your facility to suggest and document the ideal solutions for your plant to effectively and easily lockout the required equipment.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.