Cold Rolled VS Hot Rolled

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Hot-rolled steel sheet, mechanical properties are far inferior to cold processing, also inferior to forging processing, but has better toughness and ductility.

Cold-rolled steel sheet has a certain degree of work hardening and low toughness, but can achieve a good yield strength ratio. It is used for cold bending spring pieces and other parts. At the same time, because the yield point is closer to the tensile strength, there is no danger during use. Predictability, accidents easily occur when the load exceeds the allowable load

1) The cold plate is processed by cold rolling without surface oxide scale, and the quality is good. The hot plate is processed by hot rolling with oxide scale on the surface, and the thickness of the plate is lower.

2) The toughness and surface flatness of the hot-rolled sheet are poor, and the price is low, while the cold-rolled sheet has good stretchability and toughness, but the price is more expensive.

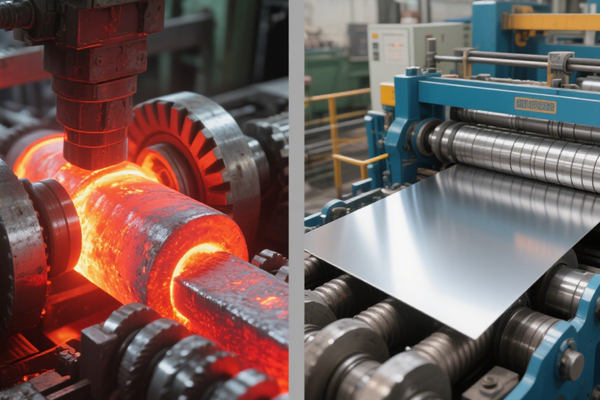

3) Rolling is divided into cold rolling and hot rolling, with the recrystallization temperature as the distinguishing point.

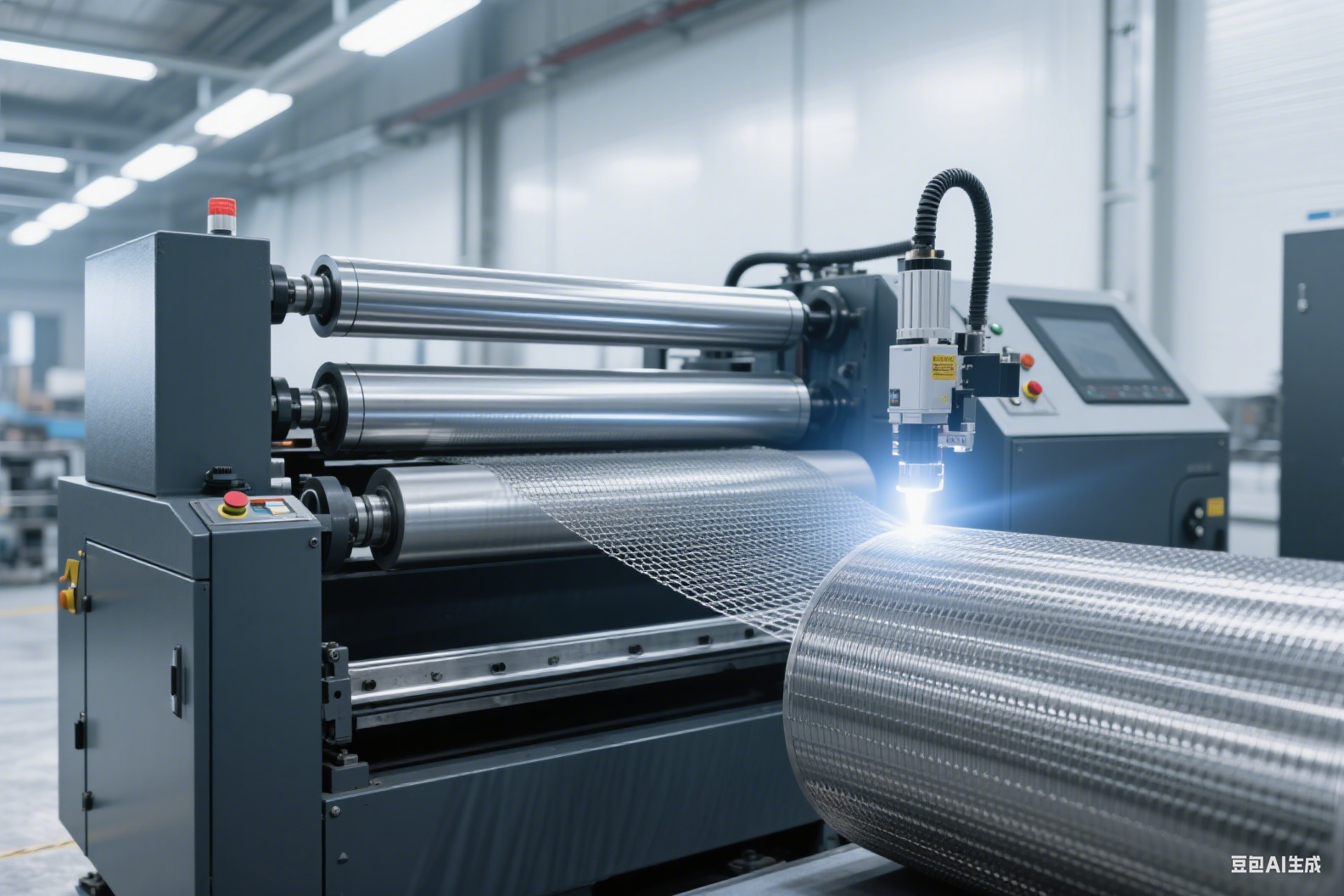

4) Cold rolling: Cold rolling is generally used to produce strip, and its rolling speed is high. Hot rolling: the temperature of hot rolling is similar to the temperature of forging.

5) The surface of the non-plated hot rolled plate is dark brown, and the surface of the non-plated cold rolled plate is gray. After electroplating, it can be distinguished from the smoothness of the surface. The smoothness of the cold rolled plate is higher than that of the hot rolled plate.

The difference between cold rolling and hot rolling in terms of processing technology: hot rolling is hot processing, cold rolling is cold processing. Hot rolling is rolling above the recrystallization temperature, and cold rolling is rolling below the recrystallization temperature. The use of cold rolling is used in home appliances such as cars, refrigerators, washing machines, as well as industrial equipment and various building materials.

The use of hot rolling, structural steel is used to produce general structural steel and welded structural steel, mainly for the production of steel structural parts, bridges, ships, and vehicles. Weather-resistant steel adds special elements (P, Cu, C, etc.), has excellent corrosion resistance and atmospheric corrosion resistance, is used in the production of containers and special vehicles, and is also used in building structures.

High-strength steel plate with excellent DRAWING function and welding function for car structural steel is used for car FRAME, WHEEL and other production. Carbon steel, alloy steel and tool steel for general mechanical structure of hot-rolled special steel are used for the production of various mechanical parts after heat treatment.

Cold rolled original sheet is used to produce various cold rolled products, including CR, GI, color coated sheet, etc.

Steel plate for steel pipe has excellent processing function and compressive strength. It is used to produce high-pressure gas pressure vessels filled with LPG, acetylene gas and various gases within 500!u0013. The steel plate for high-pressure container has excellent processing function and compressive strength. It is used to produce high-pressure gas pressure vessels with an internal volume of 500!u0013 and filled with LPG, acetylene gas and various gases.

For structural applications demanding high toughness at lower cost—like ship hulls, building frames, and crane booms—hot-rolled grades (e.g., ASTM A36, S355JR) remain preferred. Their thicker oxide scale necessitates blasting before painting but withstands dynamic loads better. Conversely, cold-rolled SPCC/DC01 steels dominate automotive subframes and appliance panels where precise forming and Class A surfaces are critical. The work-hardening effect in cold-rolled sheets allows thinner gauges for weight savings while maintaining dent resistance in door skins. Notably, high-strength cold-rolled DP780/980 grades enable safety cage reinforcements through controlled yield-point elongation, whereas hot-rolled pickled-and-oiled (HRPO) steel serves suspension arms needing balanced ductility-to-cost ratios.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.