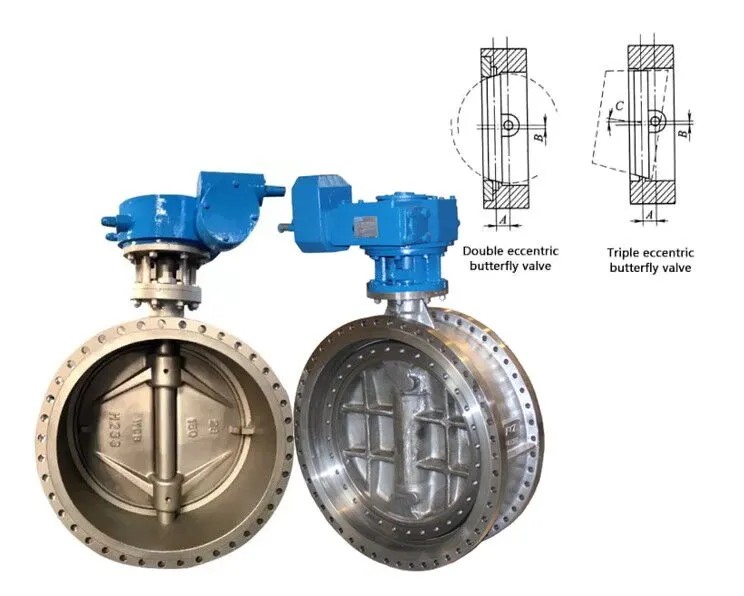

Double Eccentric vs. Triple Eccentric Butterfly Valve

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Understanding Double and Triple Eccentric Butterfly Control Valves: Design, Performance, and Application

In modern industrial systems, fluid control is a fundamental operation. Butterfly valves, as essential components in these systems, are widely employed across various sectors for their efficient performance and compact design. Among the different types available, double eccentric and triple eccentric butterfly valves stand out due to their advanced structures and specific advantages tailored to diverse operational needs. This article delves into the design principles, structural features, performance benefits, and application scenarios of these two valve types, offering insight into proper selection and usage.

What is a Double Eccentric Butterfly Valve?

The double eccentric butterfly valve is an upgraded version of the traditional concentric valve, designed to deliver improved sealing and operational efficiency in medium to low-pressure systems. By incorporating a dual offset structure, this valve significantly reduces operational torque, minimizes wear, and extends service life. It is particularly well-suited for water supply and drainage systems, HVAC applications, and wastewater treatment, where frequent opening and closing are required.

1. Design and Structural Features

The defining characteristic of the double eccentric butterfly valve lies in its dual offset design:

First Eccentricity: The valve stem is positioned behind the sealing surface centerline. This design ensures that the stem does not interfere with the seal, improving integrity and reducing the risk of leakage.

Second Eccentricity: The stem is also offset from the center of the valve bore, which causes the disc to move away from the seat during operation. This minimizes contact and friction, significantly reducing wear and required torque.

Additionally, both the disc and seat surfaces are typically spherically machined, ensuring tight shutoff via elastic deformation of the PTFE or metal seat. PTFE seats are ideal for most fluid systems due to their corrosion resistance, while metal seats are available for higher temperature applications—though their sealing effectiveness is lower under high pressure due to line contact sealing.

2. Key Performance Advantages

Reliable Sealing: The eccentric structure enhances sealing, minimizing internal leakage.

Low Operating Torque: The disc disengages from the seat with minimal friction, reducing energy consumption.

Long Service Life: Reduced wear between the disc and seat prolongs the valve’s operational life.

Versatility: Suitable for a wide range of general-purpose systems with medium or low pressure.

3. Common Applications

Double eccentric butterfly valves are widely used in systems that demand moderate sealing performance under standard operating conditions:

Water Supply Networks

Wastewater Treatment Facilities

HVAC and Refrigeration Systems

Food and Beverage Processing, where hygiene and moderate sealing are essential.

Understanding the Triple Eccentric Butterfly Valve

When handling high pressure, high temperature, or corrosive media, the triple eccentric butterfly valve is the preferred solution. By introducing a third offset—angular eccentricity—this valve achieves zero-leakage performance, exceptional durability, and robust reliability for extreme industrial environments.

1. Principle and Structure

The third eccentricity transforms the sealing surfaces into conical forms:

The disc’s outer edge forms an external cone.

The seat’s inner surface forms a matching internal cone.

The result is an elliptical, non-symmetrical sealing geometry, which eliminates the need for seat deformation. Instead, sealing relies on mechanical interference and tight surface contact.

Typically, triple eccentric valves use metallic sealing components. Advanced versions incorporate multi-layer sealing rings made of alternating stainless steel and graphite, combining resilience, heat resistance, and sealing effectiveness.

2. Performance Highlights

Zero Leakage Capability: Pure surface contact between conical seals eliminates internal leakage, even under high pressure.

Frictionless Operation: During opening/closing, the disc avoids rubbing the seat, reducing torque and increasing ease of operation.

Exceptional Durability: The minimal wear design allows for thousands of open-close cycles with minimal maintenance.

High Pressure & Temperature Resistance: Metal and composite seals withstand extreme environments and aggressive media.

3. Typical Application Areas

Due to its robust performance, the triple eccentric butterfly valve is suited for the most demanding scenarios:

Petrochemical Pipelines

Chemical Processing Plants

Natural Gas Distribution

Thermal and Nuclear Power Plants

High-Temperature Media Control in industrial food processing

Double vs. Triple Eccentric Butterfly Valves: A Comparison Guide

Feature Double Eccentric Triple Eccentric

Sealing Mechanism Elastic deformation; line contact Surface contact; elliptical conical sealing

Seat Material Soft (PTFE), optional metal Metal with layered graphite/metal seals

Pressure Rating Up to ~1.6 MPa >4.0 MPa and above

Temperature Limit Up to ~200°C Up to ~600°C or higher

Wear & Lifespan Moderate wear, shorter life Minimal wear, longer life

Operating Torque Lower than concentric, higher than triple eccentric Lowest among butterfly valves

Leakage Possible under pressure Zero leakage design

Best For Water, HVAC, light industry Oil, gas, power, chemical, high-pressure systems

Cost Economical, simpler Higher due to materials and precision

Conclusion

Both double and triple eccentric butterfly valves offer distinctive advantages based on their structural designs and operational targets. For medium to low-pressure systems with general sealing needs, the double eccentric butterfly valve offers an excellent balance of performance, cost-efficiency, and ease of use. In contrast, triple eccentric butterfly valves are engineered for extreme environments, offering zero leakage, long life, and high durability in high-pressure, high-temperature, and corrosive applications.

Selecting the right butterfly valve requires careful evaluation of system parameters such as pressure, temperature, media type, sealing requirements, and budget. A thorough understanding of these valve types ensures optimal performance, system reliability, and operational efficiency.Know more about Google SEO Directory

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.