DTG vs Screen Printing: Which Printing Method Is Best?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

When it comes to custom T-shirt printing, two of the most widely used techniques are Direct to Garment (DTG) and Screen Printing. Each has its own strengths, limitations, and ideal applications. Whether you're starting a clothing line, running a print-on-demand business, or simply curious about how your favourite graphic tees are made, understanding the difference between DTG vs screen printing can help you make the right choice.

This article explores the key differences between DTG and screen printing, covering quality, cost, speed, design compatibility, and more.

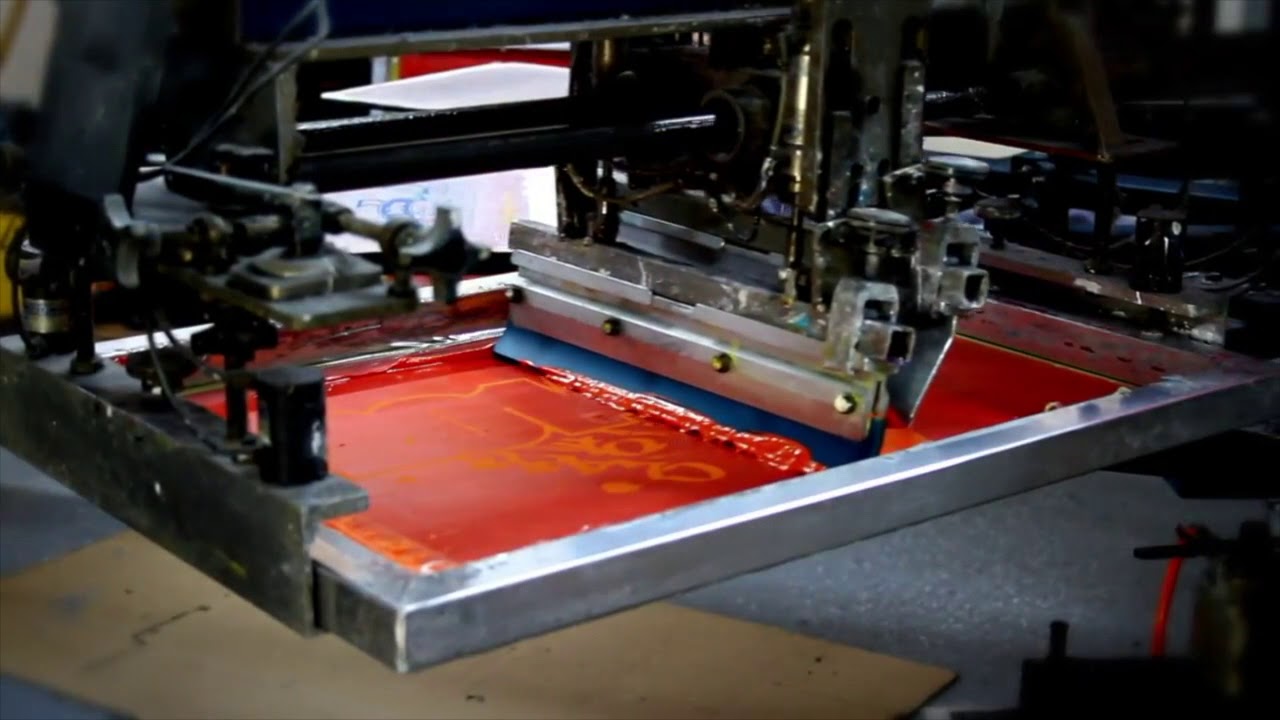

What is Screen Printing?

Screen printing, also known as silkscreen printing, is a traditional method that uses a stencil (or screen) and ink to print designs onto fabric. Each colour in the design requires a separate screen and layer of ink.

Key Features:

Uses thick, vibrant inks

Best suited for bulk printing

Ideal for designs with few colours

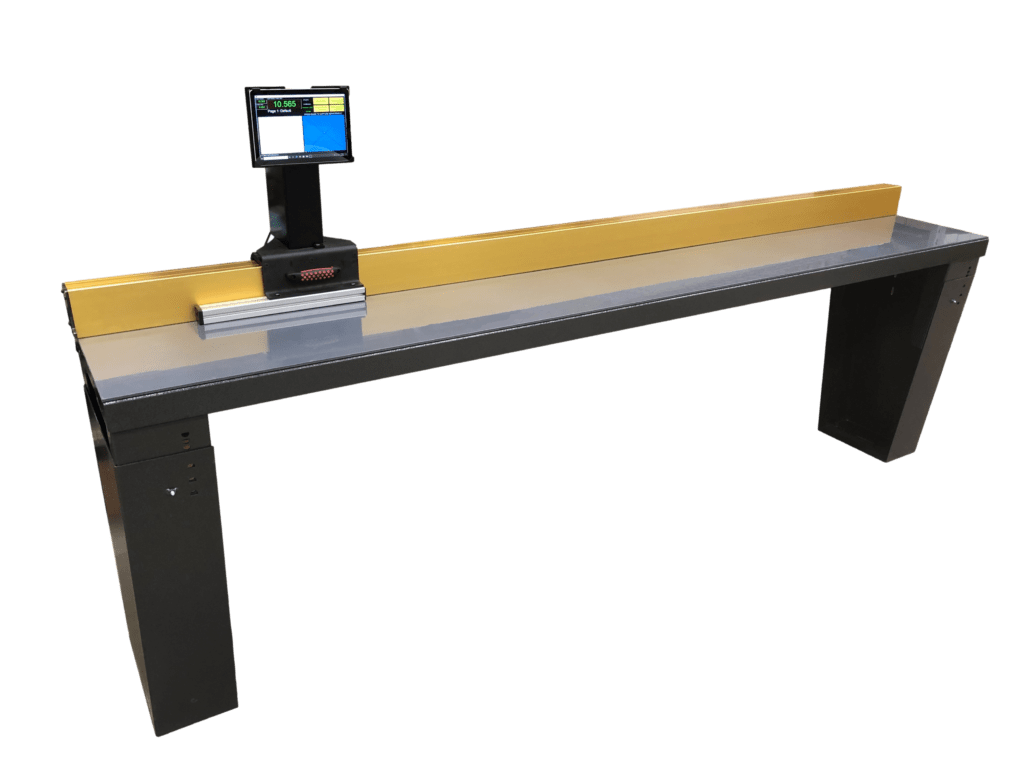

What is Direct to Garment (DTG) Printing?

DTG printing is a modern technique that uses inkjet technology to print designs directly onto the fabric, much like a paper printer. It sprays water-based ink directly onto the T-shirt, allowing for detailed, full-colour images.

Key Features:

Allows complex, multi-colour designs

Great for small orders or one-off prints

Works best on 100% cotton garments

DTG vs Screen Printing: Side-by-Side Comparison

1. Print Quality

Screen Printing: Produces bold, vibrant prints, especially on darker fabrics. Colours are rich and opaque.

DTG Printing: Excellent for high-resolution images and photo-like details. Prints feel softer and integrate into the fabric.

Winner:

For bright, bold logos – Screen Printing

For detailed artwork or photos – DTG

2. Durability

Screen Printing: Known for longevity. Prints can withstand many washes without significant fading or cracking.

DTG Printing: Durable, but may fade more quickly, especially if washed frequently or improperly.

Winner: Screen Printing for long-term durability.

3. Order Size & Cost Efficiency

Screen Printing: Best suited for large orders. Initial setup is time-consuming and costly, but the per-shirt cost drops with volume.

DTG Printing: Perfect for small runs or single items. No setup costs, but higher per-shirt cost for bulk orders.

Winner:

For 1-10 shirts – DTG

For 50+ shirts – Screen Printing

4. Design Complexity

Screen Printing: Limited to simple designs with fewer colours (typically up to 6 colours without special setup).

DTG Printing: Handles full-colour gradients, shading, and photo-realistic images with ease.

Winner: DTG Printing for complex, detailed designs.

5. Fabric Compatibility

Screen Printing: Works on nearly any fabric type—cotton, polyester, blends, and more.

DTG Printing: Performs best on 100% cotton. Results may vary on blends or dark polyester.

Winner: Screen Printing for versatility.

6. Feel of Print (Hand Feel)

Screen Printing: The ink sits on top of the fabric, so it may feel thicker, especially on large prints.

DTG Printing: Inks absorb into the fabric, producing a softer feel.

Winner: DTG for soft and lightweight prints.

7. Setup and Turnaround Time

Screen Printing: Requires setup of screens and inks for each colour. Time-consuming for small jobs.

DTG Printing: Quick setup—upload design and print. Ideal for on-demand services.

Winner: DTG for speed and convenience on small orders.

8. Environmental Impact

Screen Printing: Uses plastisol inks (which may be less eco-friendly), water use for cleaning screens, and potential chemical waste.

DTG Printing: Uses water-based inks, less waste, and is considered more eco-friendly.

Winner: DTG for environmentally conscious printing.

When to Choose DTG or Screen Printing

Choose DTG Printing If:

You’re printing fewer than 20 shirts

You want photo-realistic or intricate designs

You need fast turnaround or print-on-demand

You prefer a soft print feel

You’re focused on eco-conscious production

Choose Screen Printing If:

You’re printing large volumes (50+)

Your design uses solid colours or simple graphics

You need durable, long-lasting prints

You’re printing on a variety of fabric types

Cost efficiency in bulk is a priority

Final Verdict

Both DTG and screen printing have their place in the world of custom apparel. DTG is the best choice for detailed designs and small-batch printing, while screen printing shines in durability and cost-efficiency for large runs. Your choice should depend on your specific needs: quantity, design complexity, turnaround time, and budget.

For businesses that cater to both custom and wholesale clients, using both methods where appropriate can help maximize efficiency and customer satisfaction.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.