"Environmental Advantages of Pneumatic Pumps: Energy Savings in Manufacturing"

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

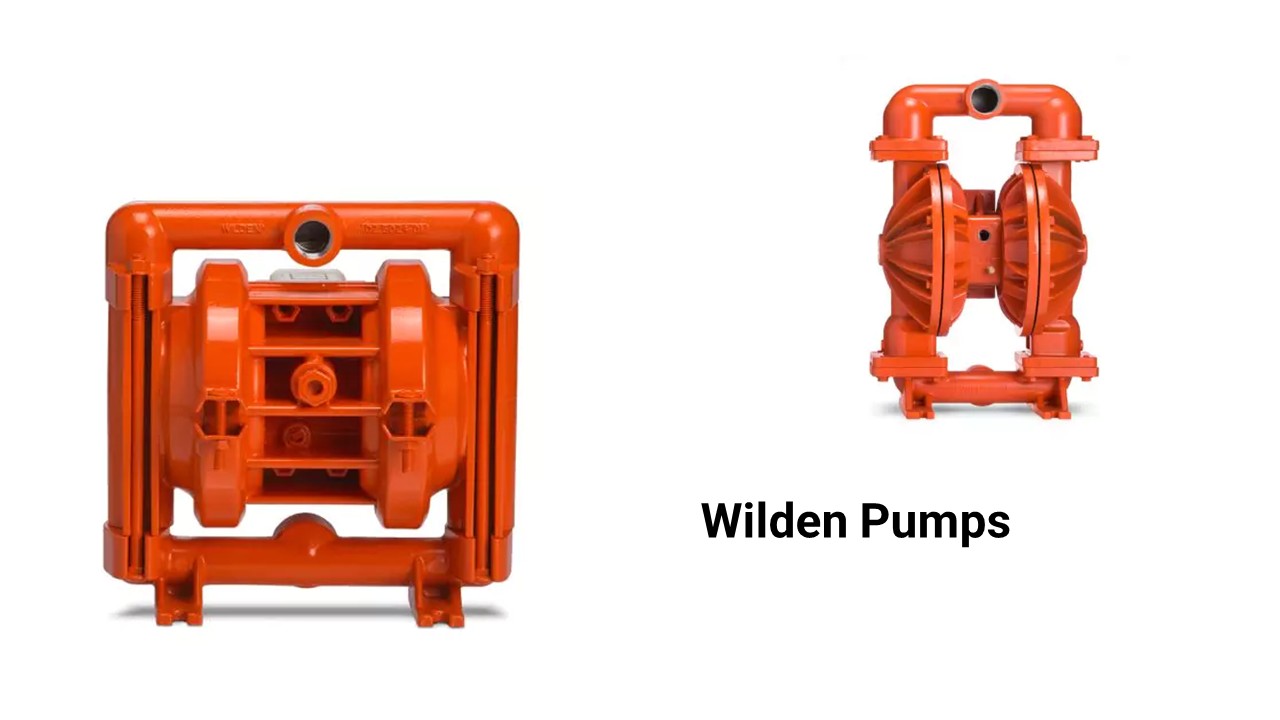

Pneumatic pumps are multi-purpose equipment that employs compressed air or gas for the aim of displacing media of any form. They are used in common applications in industries as they are convenient, efficient, and can be used to achieve a range of applications. Of many types of pneumatic pumps, pneumatic grease pumps are especially well known in industrial lubrication.

What is Pneumatic Pump?

The Pneumatic pump works on the fundamental principle of working under compressed air pressure or compressed gas to supply the fluid flow. The fundamental idea is constructed on components such as pistons, diaphragms, or impellers to provide pressure pulses to enable the fluid movement. The Pneumatic pumps operate very efficiently with abrasive chemicals and viscous fluids and are hence applied universally in manufacturing, automobiles, and minerals industries.

The Key Features:

Positive Displacement Mechanism: Offers accurate fluid transfer without backflow.

Self-Priming Facility: For operation even under conditions when the pump chamber remains unfilled.

Cost-Effectiveness: Compressed air driven, thus lesser running costs over traditional pumps.

Pneumatic Grease Pumps: A Powerful Lubrication Tool

The Pneumatic grease pumps are sophisticated pneumatic equipment that have their applications in greasing to a precise and exact level. Compressed air operates them to push grease via pressure systems to provide constant lubrication to machine parts. They are used with applications of paramount importance in those industries where accuracy and certainty of lubrication are truly necessary.

Working Principle:

Compressed air powers the air motor of the pump, resulting in reciprocating motion of the piston.

This motion triggers the pump mechanism, generating pressure to propel grease out of the reservoir.

High-pressure hoses are used to facilitate accurate delivery of grease to the point of application.

Benefits:

Precise Lubrication: Imposes the optimal amount of grease to prevent over-lubrication or under-lubrication.

High Viscosity Operation: Operates in heavy greases in harsh operating conditions.

Long Life: Operating continuously for a long time even under harsh operating conditions such as very high temperature or dirty operating conditions.

Efficiency: Conserves physical effort compared to manual process and accelerates maintenance activities.

Applications in all Industries

All these Pneumatic grease pumps have universal application in every industry:

Manufacturing: Lubricates assembly lines, robots, and manufacturing equipment.

Automotive: Ensures smooth operation of chassis parts and assembly lines.

Mining and Construction: Lubricates severe-duty gear like crushers and drilling rigs in extreme conditions.

Conclusion

Both pneumatic grease pumps and pneumatic pumps are important agents in industrial process through improved efficiency, accuracy, and dependability. Pneumatic pumps suit fluid transfer from one viscosity to another, and pneumatic grease pumps suit lubrication delivery of the optimal type to equipment components. Both are very versatile and cost-effective and, as such, very useful tools in industries that wish to maximize the output of equipment and reduce maintenance.

By harnessing the power of compressed air, these technologies keep moving higher-quality manufacturing standards in the manufacturing, automotive, mining, and construction sectors.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.