Everything About The Amazing Strip Brushes

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Among the ocean of machinery and components within the universe of factories, strip brushes are almost invisible. They are not the newest and greatest, hi-tech device on the factory floor nor can they be overlooked. They are bare-sawing brushes made for only performance, productivity, and life and they perform an unimaginable variety of functions from product making and product moving to electronics and food processing. Are you someone who wants to gather more facts about the strip brushes? If Yes. This is the best place where people can gather more facts about the strip brushes.

What Are Strip Brushes?

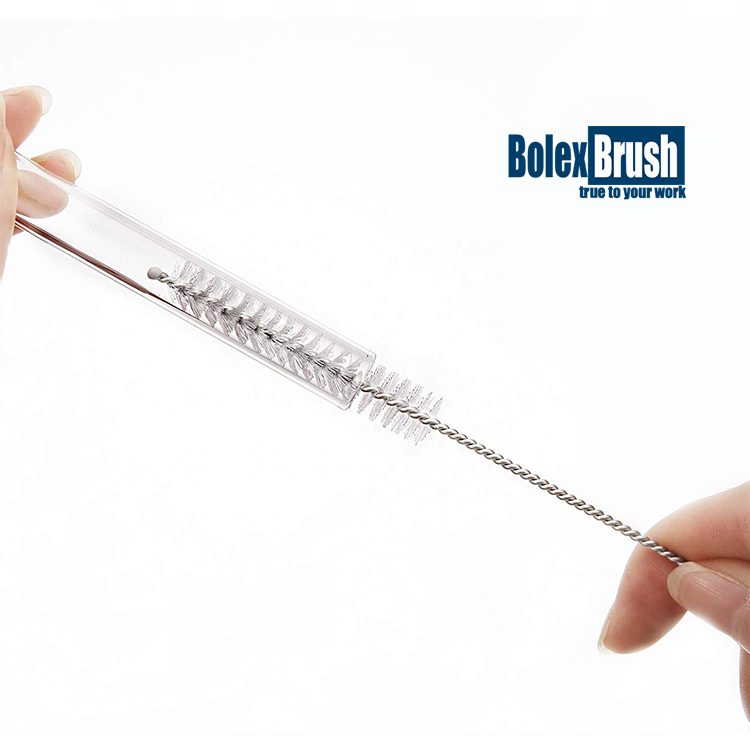

Strip brushes consist of a close row of bristles securely attached to a metal, plastic, or composite strip. They perform their primary function of providing a resilient, flexible barrier, but that is only the beginning. Gentle cleaning and product direction, equipment guarding, and static electricity management – strip brushes are wonderfully diverse. There are many benefits of choosing the strip brushes that you must know. You should gather more facts about the strip brushes for best experience.

On factory floors, they sweep parts on moving lines or prevent trash and dirt from reaching sensitive machinery. On office buildings and warehouses, they serve as weather seals to keep out dust, insects, and drafts and conserve energy.

Strip Brushes

Product handling and positioning is another major use. Strip brushes on fast conveyor lines provide a cushioned surface for sensitive or irregularly shaped products to prevent damage during smooth conveyance. Durable yet soft bristles will reduce friction, remove static, and position products for each production or packaging phase.

The stripping brushes can be of varying shapes: helical, circular, or straight; equipped with synthetic, metallic, or natural bristles. Right from closing top doors to cleaning small-sized electronic components, there could be a brush that could meet your very particular needs. The reverse stripping also can be stainless steel, galvanized steel, aluminum, or plastic a material which all is suitable for the environments as well as the working conditions.

Strip brushes most secret benefit is they are cost-effective and long-lasting. Needing zero or low maintenance and care to begin with, installed, they just get on with day after day under tough conditions. Strip brushes present a cost-efficient, effective option that will not sacrifice quality at any stage in the case of more complicated sealing or cleaning options.

Aside from providing efficient sealing on doors and hatches, strip brushes also render buildings energy-efficient. They minimize heating or cooling requirements and reduce dust and pollutant dispersion making them not just a logical option, but an environmentally friendly one at that.

While often overlooked, strip brushes play a silent but essential role in keeping operations running smoothly. Their simplicity, durability, and customization make them a go-to solution for engineers, maintenance teams, and designers alike. If you’re seeking a reliable tool that delivers on both performance and value, look no further than the trusted strip brush an unsung hero in the world of industrial maintenance. Go ahead! And claim the best benefits of the most amazing strip brushes.

Author’s Bio:

Now, its time for people to uncover the hidden benefits of the strip brushes.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.