Tube Cleaning Brushes For The Amazing Results

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In a manufacturing setting where efficiency and reliability are paramount, adequate equipment cleaning and maintenance can be the deciding factor. Among the most precious yet lesser known tools in achieving this are twisted in wire brushes and tube cleaning brushes. Both are uncomplicated in design but are instrumental in enabling machines and systems to run smoothly, safely, and at peak performance. Are you someone who wants to gather more facts about the twisted in wire brush, Tube Cleaning Brushes? If Yes. This is the best place where people can gather more facts about the twisted in wire brush, Tube Cleaning Brushes.

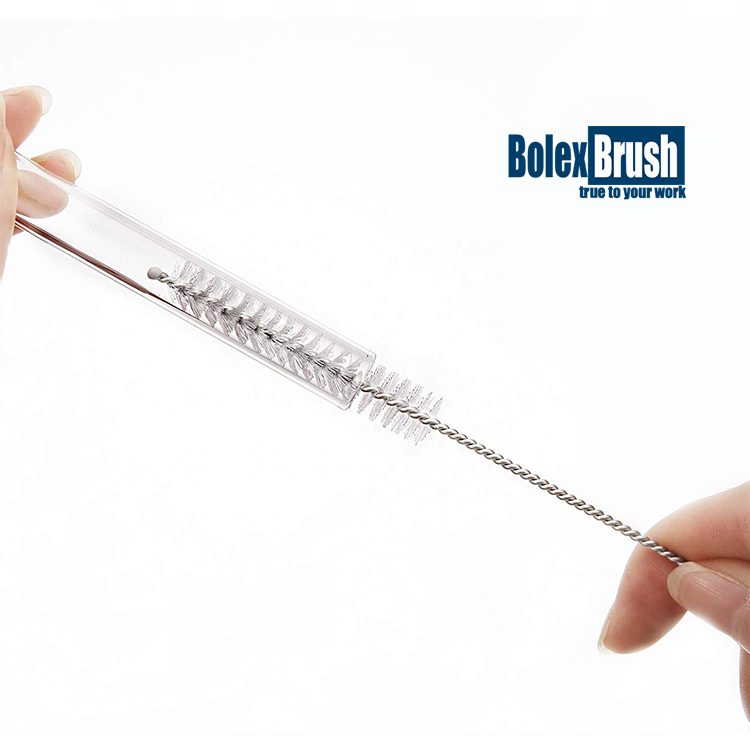

The Tube Cleaning Brushes

Twisted in wire brushes, or spiral brushes, are constructed by twisting two wires together with bristles firmly wedged between them. The structure enables the brush to sweep the interior of thin crevices such as drilled holes, tubes, nozzles, or internal grooves with accuracy. Their narrow size and flexibility enable them to be inserted into areas inaccessible to bigger tools. These brushes are employed very heavily in automotive, aerospace, plumbing, and medical industries for applications from the removal of carbon deposits to polishing and the application of lubrication. Bristle materials range from mild to highly aggressive, depending on the application.

Tube cleaning brushes also remain an important tool in tube and pipe system-reliant industries. These tubes are used to clean tube sinner surfaces and remove undesirable detritus such as scale, rust, grease, and sediment. Tube and conduit cleanliness can directly affect performance in HVAC, power generation, chemical processing, and food processing industries. A dirty or clogged tube can limit fluid flow, lessen the efficiency of heat transfer, and enhance the tendency of system failure. Tube cleaning brushes, both handheld and attached to power tools, offer system integrity without the expense of downtime. There are many facts about the Tube Cleaning Brushes that you must know. The importance of the Tube Cleaning Brushes is huge for many reasons.

Tube Cleaning Brushes

So effective are these brushes because they can clean without degrading the inner surfaces of sensitive equipment. They are durable and designed for use over the long term, and thus are a practical choice for maintenance in routine applications. Whereas twisted-in-wire brushes are well-suited to cleaning smaller, finer jobs, tube cleaning brushes are designed to thrust through harder tasks in greater systems. By using them alongside one another, they offer overall interior cleaning protection across a whole variety of industries.

Both brushes are not only cost-effective but simple to use and very versatile. They are available in different sizes and shapes to suit particular industrial uses. Spending money on the correct brush for the correct task prevents performance problems, saves repair costs, and prolongs the life of costly assets.

In an age so desperate for precision and efficiency, tube cleaning brushes and wire-in-twisted brushes remain outstanding in their ability to hold up. These very straightforward devices are scarcely high-tech or sophisticated but provide practical solutions that ensure smooth industrial process operations through cleanliness. For that reason alone, they must have a place in every maintenance kit.

Author’s Bio:

Now, its time for people to go for the twisted in wire brush, Tube Cleaning Brushes.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.