Guide to Diesel Generator Set Disassembly and Cleaning

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Comprehensive Guide to Disassembling, Cleaning, and Maintaining Diesel Generator Set Components

We are a leading generator manufacturer in China, providing cost-effective diesel generator sets and dependable power solutions tailored to meet your project requirements.

Diesel generator sets are vital power sources for a wide range of industries and infrastructure systems. Their performance and reliability directly influence the continuous operation of the systems they support. To maintain optimal performance and extend their service life, regular and thorough maintenance is essential. A key aspect of this upkeep is the proper disassembly, cleaning, and care of the generator's components. Given the complexity and number of parts involved, every maintenance step must be executed with precision to avoid compromising the equipment’s efficiency and durability.

This guide outlines the critical procedures for the disassembly, cleaning, and maintenance of diesel generator set components, emphasizing the importance of proper handling to ensure long-term functionality and operational reliability.

Preparation Before Disassembly

Before beginning disassembly, careful preparation is crucial. This includes understanding the generator's construction, preparing the necessary tools, setting up a safe and clean working environment, and reviewing technical requirements. Proper preparation minimizes errors, reduces the risk of damage, and helps ensure a smooth and cost-effective maintenance process.

1. Understanding Generator Composition

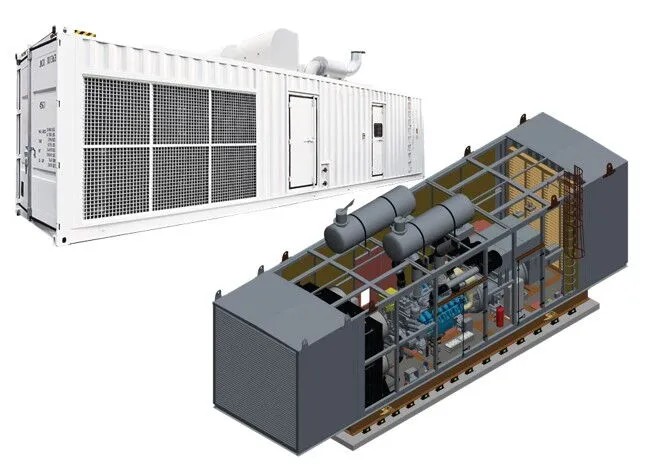

A typical diesel generator set includes multiple integrated systems: the engine, generator, cooling system, lubrication system, fuel system, starting system, and control system. Each component has specific disassembly and cleaning requirements. Technicians must be thoroughly familiar with the structure and function of each system to handle and maintain them correctly.

2. Preparing Tools and Equipment

Effective maintenance requires a comprehensive toolset, including:

Basic hand tools: wrenches, screwdrivers, torque wrenches

Specialized disassembly tools

Cleaning supplies: brushes, cloths, high-pressure washers, chemical cleaners

Advanced cleaning systems: ultrasonic cleaners or spray washers

Having the appropriate tools readily available ensures efficiency and prevents unnecessary damage during disassembly and reassembly.

3. Environmental and Safety Considerations

Maintenance should be performed in a clean, well-ventilated workspace to minimize exposure to harmful fumes or airborne particles. Technicians should wear protective gear—gloves, safety glasses, and dust masks—and follow established safety protocols, especially when working with chemicals or electrical systems.

Component Disassembly Procedures

Disassembling a diesel generator set requires a systematic approach to prevent damage and ensure accurate reassembly. The process typically involves breaking down the following key components:

1. Engine Disassembly

As the core of the generator set, the engine demands careful attention. Before starting:

Disconnect the power and fuel supply

Begin by removing the battery and cabling

Detach piping from the cooling and exhaust systems

Remove the engine casing and internal components in sequence

It’s critical to label and document each part’s position to ensure proper reinstallation. Avoid impact damage or seal compromise, which could lead to operational failures.

2. Generator Disassembly

The generator section includes the rotor, stator, and bearings. Steps include:

Disconnect all power and electrical wiring

Remove the securing elements for rotor and stator

Detach the casing and other components

Care should be taken to prevent surface damage to precision-matched parts like the rotor and stator. After disassembly, inspect for debris, corrosion, or signs of wear.

3. Fuel and Lubrication System Disassembly

Shut off all fuel and lubrication valves before proceeding. This system includes pumps, filters, and injectors, all of which must be handled carefully to prevent contamination or damage.

Maintain a precise record of the order and position of each part. Pay extra attention to sensitive components such as injectors, as their integrity is crucial for proper engine performance.

4. Control System Disassembly

The control system includes the electronic control unit (ECU), sensors, and actuators. During disassembly:

Handle all wiring with care to avoid short circuits

Use diagnostic tools to test the system’s functionality

Replace any faulty components immediately to prevent future failures

Cleaning Methods for Generator Components

Cleaning is essential to remove contaminants that can impair function or cause breakdowns. Different methods apply depending on the component and its material.

1. External Cleaning

Begin by cleaning external surfaces to prevent contaminants from entering internal systems during reassembly.

High-Pressure Water Cleaning: Removes dust and oil from surfaces.

Chemical Cleaning: Solvent application followed by scrubbing for tough stains.

Compressed Air Blowing: Clears dust from hard-to-reach areas.

2. Chemical Cleaning

Internal parts such as injectors and pumps benefit from chemical cleaning. Common solvents include:

Kerosene/Diesel: For cleaning metallic surfaces.

Gasoline: Effective against carbon buildup and grease.

Acid Solutions: Used sparingly to remove rust or oxidation.

3. Ultrasonic Cleaning

Ideal for delicate or intricately shaped parts, ultrasonic cleaning uses high-frequency waves to remove stubborn deposits from small crevices without damaging the component.

4. Mechanical Cleaning

Manual scrubbing or scraping is suitable for larger components or those incompatible with chemical methods. Care must be taken to avoid surface damage.

5. Drying and Inspection

After cleaning, all components must be thoroughly dried using air drying or drying machines. Inspect each part to confirm complete removal of dirt, oil, and cleaning agents. This ensures readiness for reassembly and continued performance.

Maintenance and Component Care

Ongoing maintenance is key to sustaining the generator set’s performance and preventing unexpected failures.

1. Lubrication

Lubricate the engine, generator, and moving components regularly using the appropriate oil for the operating conditions. Periodically test oil quality and replace as needed to prevent wear.

2. Routine Inspection and Replacement

Check parts prone to wear—seals, bearings, and injectors—for signs of damage or loosening. Promptly replace worn components to avoid secondary failures.

3. Corrosion Protection

For idle generators, corrosion prevention is critical:

Apply rust inhibitors and lubricants to exposed metal surfaces

Ensure protective covers and seals are intact, especially in outdoor environments

Conclusion

Proper maintenance of diesel generator sets—including systematic disassembly, effective cleaning, and routine care—is essential for ensuring reliable operation and extending service life. With a well-planned maintenance strategy, the right tools, and adherence to safety protocols, technicians can keep diesel generators running smoothly, reduce downtime, and avoid costly repairs. Consistent attention to detail in every maintenance step ensures the generator remains a dependable power source for years to come.Know more about Google SEO Directory

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.