How Design Instrumentation Training Enhances Efficiency in Industrial Systems

Efficiency becomes key in the industrially fast-moving environment of today. As industries become increasingly reliant on technology, automation, and precision, so does the need for professionals who can construct and maintain such systems grow unprecedentedly. Design instrumentation training, therefore, plays a paramount role in equipping engineers and technicians with the required expertise to work through the intricacies of modern industrial systems and optimize operations with a view to maintaining smooth functionality. This blog shall outline how design instrumentation training and smart plant instrumentation training provide ways of improving efficiency in industrial systems.

Understanding Design Instrumentation

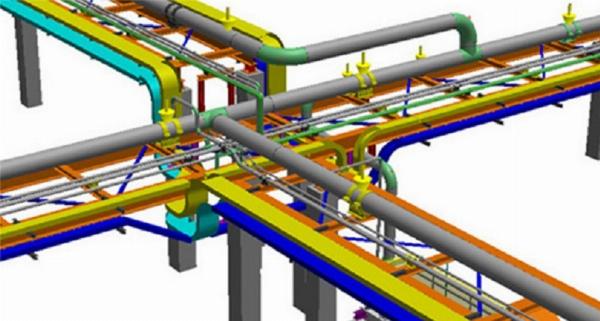

Instrumentation design involves choosing, installing, and operating instruments used in industrial systems for continuous monitoring and controlling of various parameters like pressure, temperature, flow, and level, among others. Since they play a very vital role in the functioning of a system, their malfunction or incorrect functioning will lead to costly down times, inefficiencies, or even safety hazards.

The professional should specially design instrumentation Training so that they can maximize operability. In this way, they will know the functioning of different instruments, how to install and calibrate them, and also how to troubleshoot in case specific problems occur during operability.

Key Benefits of Design Instrumentation Training

Smarter Efficiency of Systems Those who are better trained can design and install instrumentation systems that are truly efficient. Utilizing appropriate instruments for specific applications would allow engineers to optimize the processes, cut down on wastes, and thus allow the operation of the system at peak performance. It results in reduced energy consumption and lowers operational costs.

Improved Accuracy Industrial instruments must be accurate; a small deviation may result in disastrous situations. The training of instrumentation design enables these professionals to choose proper instruments and further tune them for better accuracy; hence, the entire system operates within the desired parameters and meets the production objectives as well.

Reduced Downtime:

Unplanned downtime is one of the major concerns of any industrial system, characterized by lost productivity and increased costs. Good training in instrumentation design helps the engineer to anticipate possible problems and install reliable and easy-to-maintain systems. This minimizes the chances of system failure and ensures that a problem, if it occurs, is identified promptly and resolved in record time.

Improved Safety Industrial systems operate under extreme conditions at times; the safety of the equipment, let alone personnel, is of utmost importance. In design instrumentation training, much importance is given to instrument selection in order to meet safety standards as well as operate at conditions which the plant experiences. This averts accidents and the system also complies with regulatory requirements.

SmartPlant Instrumentation Training and Its Role

The concept of smart plants is, therefore, gaining momentum as the industrial systems are becoming integrated with a complex nature. It is here that the training on smart plant instrumentation focuses on integrating advanced technologies like the Internet of Things, Artificial Intelligence, and cloud computing into industrial systems. This course will provide professionals with the competency in designing, implementing, and maintaining smart instrumentation systems that are capable of availing data in real time while offering predictive maintenance.

Real-Time Monitoring One of the fundamental benefits of intelligent plant systems is the ability to perform real-time process monitoring. Smart plant instrumentation training empowers individuals with more than just designing such a system-a system that can continuously monitor a process through the acquisition of data-but also analyzing the resultant information in a way that operators can identify potential issues before they escalate. With this comes more informed decisions and, thus, increased efficiency.

Predictive Maintenance With smart plant instrumentation, industries can move from reactive maintenance to predictive. In other words, the potential failure in equipment can be forecast and dealt with before it happens to create further downtime. Smart plant instrumentation training helps engineers design such systems that make use of predictive analytics to save industries time and money by not allowing costly breakdowns to occur.

The smooth integration of all systems and technologies is crucial to smart plants. Smart plant instrumentation training teaches trainees how to design and deploy such systems that allow free and clear communication among each other for the collective harmony of all components within the industrial system. All this translates to increased overall efficiency and quicker response times to alterations in production conditions.

Why Design Instrumentation Training is Essential for Modern Industries

With greater relevance of industrial efficiency than ever, the training in instrumentation design needs to be thorough. In this regard, both design instrumentation training and smart plant instrumentation training will provide professionals with tools and knowledge for improving system efficiency, accuracy, and safety.

Specialized training will help industries prepare their personnel for the rigors modern systems present. These, in turn, ensure more reliable operations, with minimal down times and greater productivity overall.

Conclusion:

Looking for expertise in design instrumentation or smart plant instrumentation? Well, at Rudraja Engineers, you get full training on equipping professionals with the proper skill to counter emerging industrial competition. Our application-based courses, in real time, are conducted by expert faculties who help you immediately apply your gained practical knowledge in the industry.

Call to Action: The next step in your career is only a call away. Contact Rudraja Engineers today for more information about our training programs and how we can help you enhance efficiency in your industrial systems!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.