How Nanotechnology Is Reinventing Plastic Materials

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Plastic is found in every aspect of life today, for instance, it’s in packaging, electronics, vehicles and medical field. Still, compared to the latest plastic materials, conventional kinds may lack in toughness, high-heat resistance or practicality. Let’s focus on nanotechnology and plastics. This new field is completely reshaping the development, purpose and perception of plastics.

The Nanotech Revolution in Plastics

Visualize plastics that can repair themselves, notice changes in the environment or beat metals in being both strong and heatproof. This is actually happening today because of nanotechnology in plastics. By using nanotechnology, we can handle materials at the smallest level which allows us to achieve things believed to be impossible.

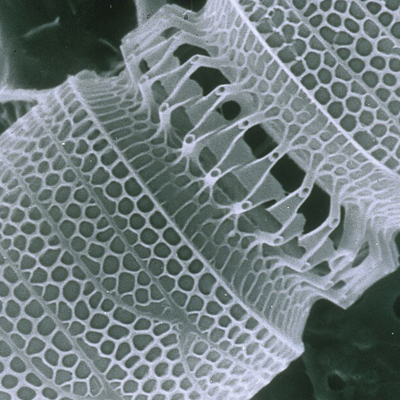

Essentially, combining nanoscale materials with polymer components is what nanotechnology in plastics is about. Examples of nanomaterials are nanoparticles, nanotubes, nanoclays and nanosilica, all of which help turn regular plastics into improved kinds and even high-performance plastic materials.

What Are Nano-Enhanced Plastic Materials?

That brings us to the question: What makes nano-enhanced plastic materials special when compared to ordinary plastics? The key to it is found in how large the plant is and the purpose it serves. Despite being very little in size, nanomaterials are loaded with significant power. If added to polymers, conductive materials usually change the qualities of plastics by making them lighter, stronger, more conductive and more environmentally friendly.

Since this change has occurred, it is now possible to make plastics that perform better than ever imagined before. As an illustration, using carbon nanotubes as reinforcement for plastic parts in cars reduces the weight and makes them better in crash simulation tests than metal-only ones.

Combining nanomaterials with plastics through nanocomposites leads to practical results with great performance and gives rise to high-performance plastic materials.

Nanocomposites in Plastic Manufacturing: The Game Changer

Nanocomposites in plastic manufacturing have become a very exciting new trend in nanotechnology for the manufacturing of plastics. Plastics that become nanocomposites are mixed with small particles of graphene, carbon nanotubes or nanoclays. Fillers play a major role in upgrading the strength, heat stability and resistance to different gases.

In terms of strengthening and increasing the durability of plastic, nanocomposites offer answers that traditional improvement techniques fail to provide. A minor amount of nanoclay can make plastic much tougher and more flame resistant while not increasing its weight. Therefore, these plastics are popular in aerospace, automotive and sports equipment factories for producing high-performance plastic materials that meet industry demands.

Benefits of Nanomaterials in Plastic Product Design

The scope of using nanomaterials in plastic design surpasses several areas. In addition, they make plastics more durable and lighter, while adding useful new aspects. Plastics with added silver nanoparticles, for example, are used in medical as well as food packaging since they are antibacterial.

In addition, there are a number of more benefits to note. UV resistance, less loss of food quality due to gas and conductivity are among the features nanomaterials provide in electronics plastics. They are much more than just improvements; they change the basic approach used in smart plastics technology, leading to the rise of high-performance plastic materials.

Smart Plastics Technology: Intelligence at the Molecular Level

Smart plastics adapt their performance when things like temperature, pH or moisture come into contact with them. As a result of nanotechnology in plastics, these materials are able to respond differently as their environment changes. Some plastic coatings can change their color when they come in contact with specific chemicals and some packaging can monitor how fresh food stays in real time.

A lot of positive effects can be seen in this area.

Both wearable sensors and drug-delivery systems in healthcare use plastic materials that are enhanced with nanotechnology. They are able to notice changes in the body and provide medications accordingly, making therapy more suited to each person’s needs and turning them into high-performance plastic materials designed for smart functions.

Nano Additives for Polymers: Customizing Performance

How these materials have become so innovative is thanks to the application of nano additives for polymers. They are simple and small agents that are mixed with the plastic to boost its capabilities for different functions. For example, if the goal is to improve flexibility, conductivity or make plastic biodegradable, these agents like molecular engineers to change every part of plastic.

One recent trend in the industry is combining various nanoparticles to balance advanced plastic materials’ properties. You can make plastics with both strength and strong thermal stability by joining graphene and silicon dioxide, suitable for electronics or aerospace parts that require high-performance plastic materials.

How Nanotechnology Improves Plastic Strength and Durability

It is obvious that nanotechnology greatly influences both plastic’s strength and durability. Very small nanoparticles attach to the polymer chains which results in an extremely strong and yarr bond in the composite. The weaving at the nanoscale enables plastics to fulfill the same roles where metals were once used.

As an example, in construction and car manufacturing, plastics combined with nanocarbon have displayed a higher ability to resist impacts, wear and tough temperatures. These abilities are influencing the way engineers and designers pick different materials that can compete as high-performance plastic materials.

Innovations in Nanotechnology for Plastic Manufacturing

Nanotechnological breakthroughs for plastic production are moving very fast, starting in labs and continuing on factory floors. The latest progress enables the use of nanomaterials in 3D printing materials which can make tough plastic parts easily when needed. People are working on new nanoplastics that keep their strength while using fewer resources.

Factories are now using their resources more effectively than they did before.

Companies applying nanotechnology can process materials more efficiently, spend less energy, use fewer raw materials and still improve the final product’s quality. Such technological improvements encourage using nanocomposites in plastic industry more widely, especially for producing high-performance plastic materials at scale.

The Future of Nano-Enhanced Plastic Materials

It looks like the opportunities for nano-enhanced plastic materials will keep increasing. Several studies aim to design materials that perform well, repair themselves when damage happens, detect problems and respond to different stresses. It is possible that AI and nanotechnology will soon allow plastics to learn by themselves and update their actions depending on their environments.

It is expected that smart plastics will help to improve gadgets, packing materials, cars and helmet linings used by the armed forces. Because the difference between synthetic and intelligent materials is diminishing, nanotechnology in plastics will keep being central to developments in this field, particularly in the creation of high-performance plastic materials.

Wrapping Up: A Paradigm Shift in Plastic Design

Other than boosting their performance, nanotechnology also helps set new standards for plastics. With better durability, lightness and smart technology along with being friendly to the environment, the changes are impressive.

There is much more that nanoscience can do with plastic materials. With more benefits of nanotechnology in plastic design being seen, money and resources will be allocated for increased research and investments. By using creativity and science, people are breaking new ground and making old materials active and useful in today’s world.

The ultimate truth is that advanced plastic materials added with nano additives for polymers are really a brand-new idea, not only better. Because of new developments in nanotechnology for making plastics, it is expected that we will have plastics that are smarter, stronger, more sustainable and more purposeful in the future — a future driven by high-performance plastic materials....Explore more

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.