How Smart Advanced Manufacturing Boosts Efficiency and Quality in Modern Industries?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Manufacturing has undergone a remarkable transformation with the introduction of smart technologies. Traditional production methods are being replaced by intelligent, data-driven systems that enhance efficiency and quality. This shift is redefining how industries operate, creating a seamless connection between digital technology and physical production processes. Businesses that integrate smart advanced manufacturing gain a competitive edge by streamlining workflows, reducing errors, and maximizing productivity.

Automation as the Foundation of Efficiency

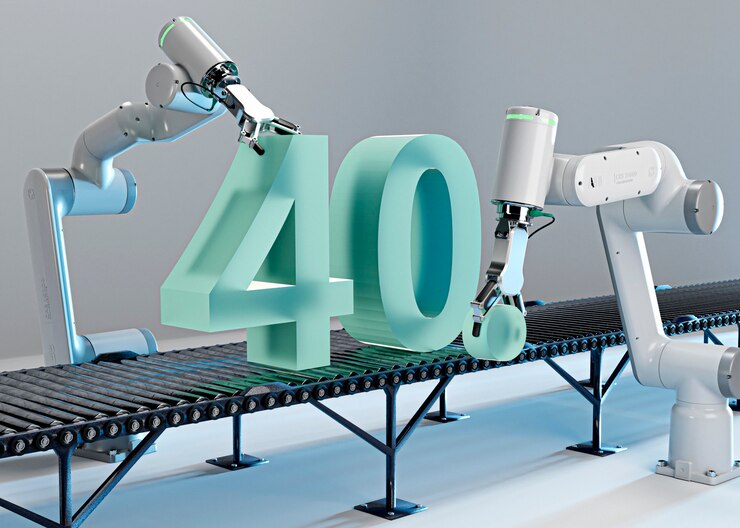

Automation plays a key role in smart manufacturing by minimizing manual intervention and increasing production speed. Robots, artificial intelligence, and machine learning work together to handle repetitive tasks with precision. This not only reduces the risk of human error but also ensures consistent product quality. Automated systems analyze real-time data to optimize processes, making production lines more responsive to fluctuations in demand.

Predictive maintenance further enhances efficiency by using sensors and analytics to detect potential equipment failures before they occur. Instead of reacting to breakdowns, manufacturers can schedule repairs proactively, avoiding costly downtime. With interconnected machinery communicating through the Internet of Things, factories operate with unprecedented synchronization, boosting overall efficiency.

Improving Quality Through Smart Manufacturing

Quality control is a critical aspect of modern manufacturing, and smart technologies provide innovative solutions to maintain high standards. Advanced sensors and computer vision systems detect even the smallest defects in products, ensuring that only flawless items reach the market. Machine learning algorithms analyze production data to identify patterns that may indicate quality issues, allowing adjustments before defects become widespread.

Real-time monitoring provides manufacturers with instant feedback on performance metrics, helping them fine-tune their operations. This level of control minimizes waste and ensures that products meet industry regulations and customer expectations. With digital twins—virtual replicas of physical assets—manufacturers can simulate production scenarios and test improvements without disrupting operations. These digital models help refine processes and enhance product quality without physical experimentation.

Data-Driven Decision Making for Smarter Operations

Manufacturing success increasingly depends on data-driven decision-making. Smart factories generate vast amounts of data, providing valuable insights into operational efficiency. By leveraging advanced analytics, manufacturers can identify bottlenecks, predict supply chain disruptions, and optimize resource allocation. Artificial intelligence processes complex datasets in real time, offering actionable insights that improve production planning and reduce costs.

Supply chain management also benefits from real-time data analysis. By tracking inventory levels and material flow, manufacturers can avoid overproduction or shortages. Automated logistics systems coordinate deliveries precisely, reducing lead times and improving customer satisfaction. The integration of blockchain technology ensures transparency and traceability, further strengthening supply chain reliability.

Enhancing Sustainability in Manufacturing

Smart manufacturing is not only about efficiency and quality but also about sustainability. By optimizing energy consumption and reducing waste, advanced technologies contribute to environmentally responsible production. Energy-efficient machinery, powered by smart sensors, minimizes excess power usage and lowers operational costs. Data-driven insights help manufacturers develop greener production methods, reducing carbon footprints and complying with sustainability regulations.

Recycling and material optimization strategies benefit from smart systems that track and minimize resource waste. Additive manufacturing, such as 3D printing, allows precise material usage, eliminating excess raw material consumption. With a focus on circular economy principles, smart manufacturing enables industries to produce high-quality goods while minimizing environmental impact.

Human Collaboration with Smart Systems

Despite the rise of automation, human expertise remains vital in smart manufacturing. Instead of replacing jobs, technology enhances human roles by reducing manual labor and allowing workers to focus on complex decision-making. Collaborative robots, or cobots, assist employees in assembly lines, ensuring safety and efficiency. Augmented reality tools provide real-time guidance to workers, improving accuracy and reducing errors.

Workforce training is evolving alongside smart technologies, with digital learning platforms helping employees adapt to new systems. Smart manufacturing does not eliminate human involvement but enhances it by empowering workers with the tools needed for precision and innovation.

The Future of Smart Advanced Manufacturing

Industries that embrace smart manufacturing are poised for long-term success. With continued advancements in artificial intelligence, robotics, and data analytics, production processes will become even more refined. The expansion of edge computing and 5G connectivity will further enhance real-time decision-making capabilities, making factories more agile and responsive.

Companies that invest in smart technologies today are securing a more efficient, sustainable, and high-quality future. By integrating automation, data-driven decision-making, and sustainability initiatives, modern manufacturing is not just improving, it is redefining the industry.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.