Key Features to Look for in the Best Automation Programs Institute

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

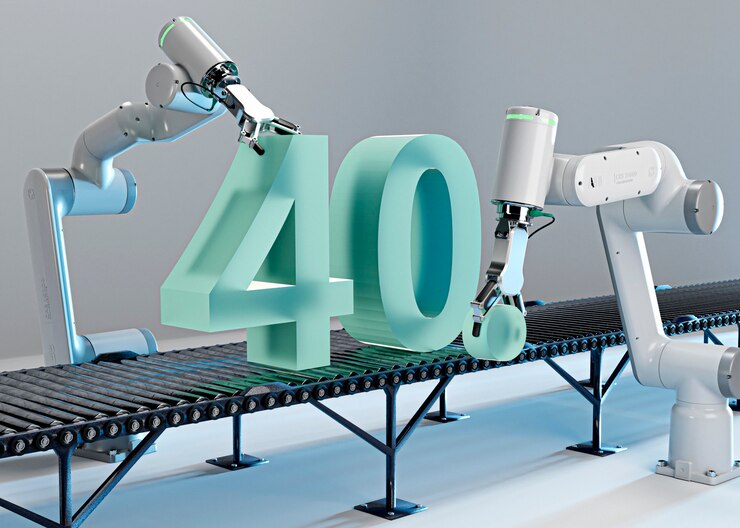

Automation is reshaping global industries at a scale and speed never seen before. From automotive plants to smart logistics, precision systems and data-driven machinery are taking over repetitive, manual processes. In this fast-evolving space, professionals need more than surface-level training, they need real, practical skills. That journey starts with choosing the right institute. But what defines the best automation programs institute?

It’s not about size, branding, or marketing. It’s about deep, relevant content, hands-on learning, career integration, and future-ready instruction.

Industry-Relevant Curriculum That Keeps Up With Change

Top-tier automation programs teach what employers actually need. Their curriculum evolves as the technology does. Students aren’t just reading about programmable logic controllers, they’re writing logic, testing it on live panels, and seeing real results.

The best programs go beyond introductory wiring or relay logic. They include SCADA, HMI development, industrial networking, motion control, and sensor integration. Courses are often linked to developments in smart factories and connected manufacturing. If the syllabus still focuses on outdated systems, or doesn’t mention robotics or IIoT, that’s a sign the program isn’t keeping pace.

Real Equipment, Not Just Theory

No one becomes industry-ready by watching videos or reading manuals alone. In automation, skills are built through physical interaction. You learn by doing, troubleshooting, and adapting.

A best automation programs institute is defined by its lab. It’s where concepts become tangible. Students work with industrial PLCs from major manufacturers, experiment with HMI screens, and solve system-level challenges that mimic plant-floor situations. Equipment quality, access hours, and instructor-guided exercises make a major difference in outcomes.

Faculty With Field Experience

A seasoned automation professional brings more to the classroom than just academic instruction. They explain what happens when a VFD fails under load, or how to manage signal noise in an industrial environment.

That experience only comes from hands-on industry experience. A strong institute invests in instructors who’ve worked in real-world settings and who can mentor students beyond textbooks. When trainers bring practical logic, risk-based decision-making, and troubleshooting scenarios into class discussions, students absorb more than steps, they learn thinking patterns.

Career-Integrated Learning

Great programs prepare students not just to pass, but to perform. Beyond technical modules, the learning experience must include project work, resume development, interview simulations, and industry readiness checks.

This is where a weak program gets exposed, if students finish without the ability to speak confidently about systems they’ve worked on or projects they’ve delivered, something’s missing. Strong institutes embed career skills throughout the course rather than waiting until the final weeks.

Real Ties With Industry

The best automation programs institute doesn’t operate in isolation. It collaborates with manufacturers, system integrators, robotics firms, and energy plants. These partnerships often open doors for internships, plant visits, or job placements. That speaks to the trust they place in the training provided. Guest lectures, employer panels, and real-world challenges brought into the classroom signal a learning environment aligned with industry needs, not just academic requirements.

Evaluating Through Projects, Not Just Exams

Testing should reflect reality. That means capstone projects, live systems development, error handling exercises, and full-cycle PLC programming assignments. Some of the best learning happens when things go wrong, and students are asked to fix them. That’s why top programs emphasize real failure scenarios: sensors misfiring, system timeouts, HMI communication breakdowns. These controlled problems help build the judgment and resilience needed in live operations.

Scalable for All Levels of Learners

Automation isn’t just for engineers. Electricians, technicians, maintenance leads, and even data professionals are entering the field. A strong institute knows how to teach students from different backgrounds without compromising depth.

That often means offering layered learning, introductory theory for beginners, mid-level system design for upskillers, and advanced automation diagnostics for experienced professionals. It’s about inclusivity, but without dilution.

Certifications That Travel Across Borders

For anyone looking to work with multinational companies or abroad, globally relevant certification matters. Vendor-authorized training (e.g., Siemens, Rockwell, Schneider) is a solid sign of quality.

The best automation programs institute will also structure its course content in line with global standards such as ISA-88, IEC 61131, or ISO 50001 (energy management). This gives learners the flexibility to apply their skills in any geography, and the confidence to stand out in competitive hiring pools.

Alumni Outcomes and Institutional Transparency

One of the most reliable indicators of a program’s quality is its alumni. Are past students working in core roles? Do they recommend the program? Are they mentoring others?

Equally important is transparency. A credible institute won’t hesitate to publish details about its syllabus, trainer credentials, placement records, and fee structure. It will also showcase past student work and provide channels to connect with alumni. If basic information is hidden or vague, that’s a red flag.

Final Thoughts

In a world where automation drives growth across every industry, your choice of training institute can define your career trajectory. The best automation programs institute isn’t the one with the biggest billboard. It’s the one with the strongest labs, the most aligned curriculum, seasoned faculty, and students who leave ready, not just certified.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.