How to Choose Durable Industrial Storage Racks That Actually Work for Your Warehouse?

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

If you require bulk inventory storage or heavy items, the right Industrial Storage Racks are essential to the success of your business. In addition to helping prevent product damage, Racking Systems improve handling speed, and ensure your warehouse runs safely and efficiently, so choosing the right racking system is essential. If you are upgrading or starting from scratch, these warehouse storage racks should provide strength, reliability, and heavy-duty performance.

1. Know Your Load – One Rack Doesn’t Fit All

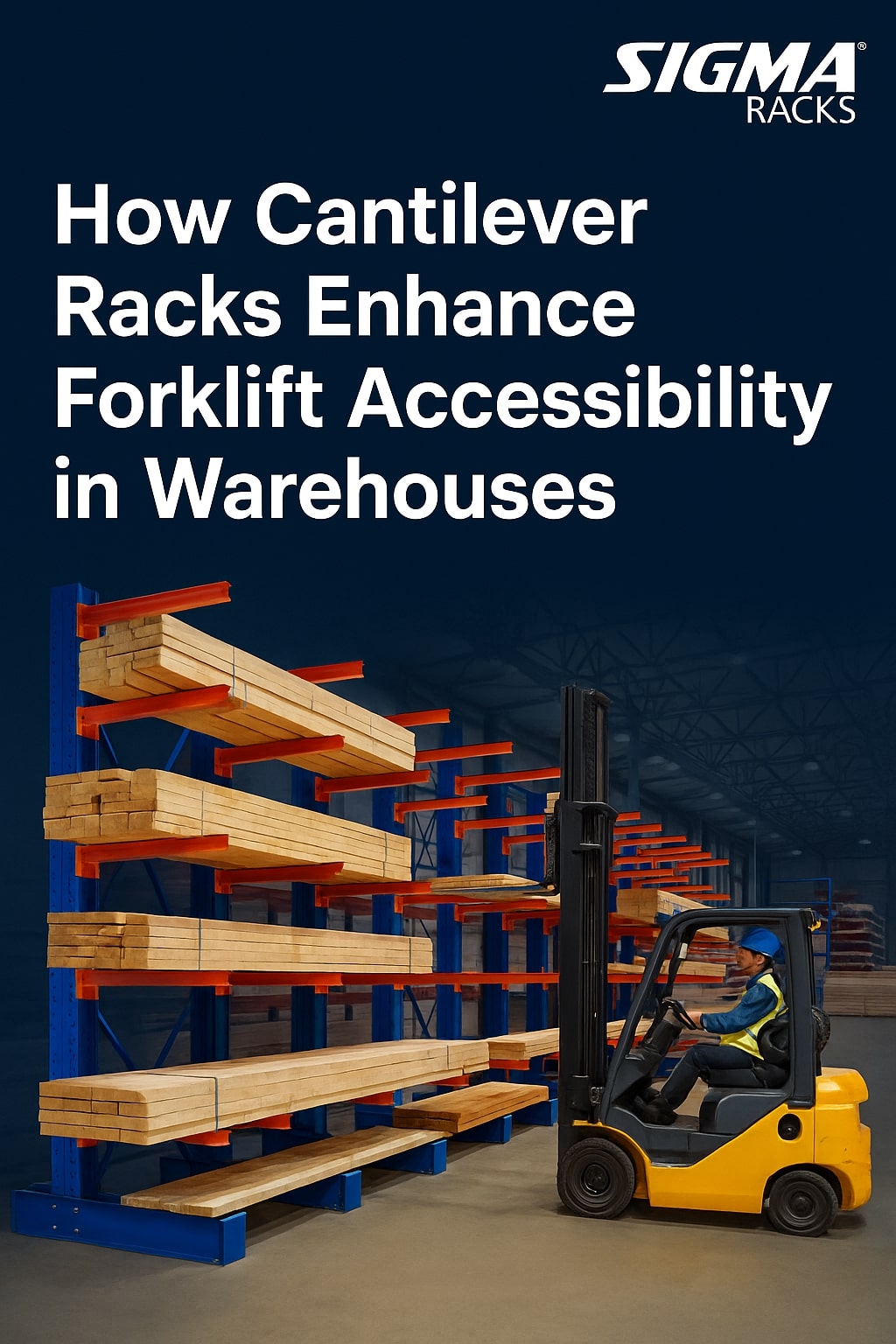

Before picking any rack, ask yourself: What exactly are we storing? Pallets, Long items like rods or pipes? Small inventory boxes? This makes a huge difference. For pallet-based goods, warehouse storage racks or pallet racking systems are your go-to. But for long, bulky materials, a Cantilever Racking System is a much better fit.

Just make sure the racks are genuinely built to carry the weight. Always check weight capacities, frame build quality, and whether the shelves are reinforced for extra durability.

2. Use Your Space Smartly – Not Just Fully

It’s tempting to just fill up every inch of space with racks, but that’s not always the best move. Smart racking means optimizing—not cramping. If floor space is tight, think vertically. Adjustable shelving and Mezzanine Floor Systems help you build upwards while keeping walkways and handling zones open. Your workers should be able to move freely without tripping over inventory or struggling to access items.

3. Strength is More Than Looks

There are many racks that look tough on the first day, but cannot stand up to daily wear and tear. Choose racks that are made from steel and powder-coated to prevent rust. You will want something that can withstand forklifts, weight shifting, and rough use. Good industrial storage racks are built to last — not just survive a few months.

4. Is It Practical for Daily Use?

Installation of racks is one thing, but actually utilizing them is another. Be sure beam heights match product sizes, and shelves can be easily adjusted when needed. Racks should not require your staff to bend, stretch, or climb to get things in and out, and a practical layout will make loading and picking faster and safer.

5. Manufacturer Matters More Than You Think

Choose a manufacturer who doesn't just provide racks — they offer layout advice, customization options, and after-installation support to set them apart from all other sellers. Sigma Racks offers a wide range of custom solutions, including shelving systems, mezzanine floors, and warehouse storage racks, all manufactured in-house with automation and factory-direct pricing.

Conclusion:-

Buying storage racks isn’t just about ticking boxes. It’s about investing in something that will support your daily operations, help reduce product damage, and boost overall efficiency. A smart racking system can save you thousands over time.

So before you buy, slow down and ask — is this really built for the way you work?

🔧 Customized storage systems

🏭 Automated manufacturing

🚚 Pan India delivery & support

🌐 www.sigmastorage.com

📞 +91-9670777737

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.