How to Choose the Best Materials for 4-Layer PCB Boards

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

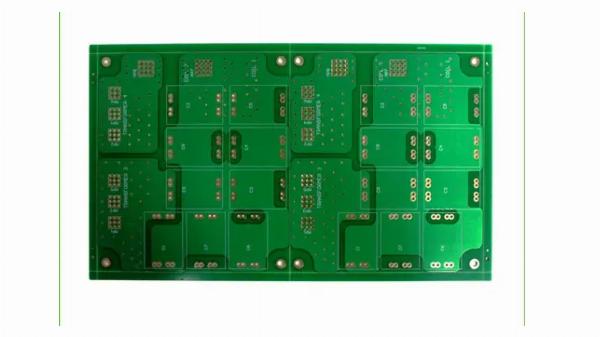

When designing a 4-layer PCB board, picking the right materials is crucial. Your choices will affect the board's performance, durability, and even cost. Here’s a simple guide to help you make the best material choices for your 4-layer circuit board.

Understanding PCB Layers

A 4-layer PCB board consists of four distinct layers. These include two signal layers and two power/ground layers. The layers are separated by insulating material, which helps maintain the board's integrity and performance. Choosing the right materials for these layers ensures that the board functions as intended and remains reliable over time.

Key Materials for 4-Layer PCB Boards

FR-4: The Most Common Choice: For most 4-layer PCB boards, FR-4 is the go-to material. It’s a type of fiberglass laminate that’s both affordable and reliable. FR-4 offers a good balance of strength, flexibility, and electrical insulation. It’s especially popular in consumer electronics due to its cost-effectiveness and durability.

Copper Foil: Essential for Conductivity: Copper foil is used for the conductive layers on the PCB. For 4-layer circuit boards, copper foil is crucial as it carries electrical signals between different layers. The thickness of the copper foil can affect the board's performance. Thicker copper foils can handle higher currents but might increase the board’s cost.

Aluminum: For Heat Dissipation: Aluminum is a popular choice for PCBs that require good thermal management. It is often used in applications where heat dissipation is critical, such as LED lighting and power electronics. Aluminum PCBs are designed with a layer of aluminum for effective heat transfer, helping to keep components cool and prevent overheating. This material is more expensive than traditional FR-4 but offers excellent thermal conductivity.

Ceramic: High-Performance Applications: Ceramic materials are used in specialized PCBs that require high performance and reliability. Ceramic PCBs offer superior thermal conductivity and excellent electrical insulation. They are ideal for high-frequency applications and environments where high temperatures are a concern. Although they are more costly than other materials, their performance benefits often outweigh the additional expense.

Core Material: The Foundation: The core material of a PCB board forms the base for all other layers. For a 4-layer board, the core material is usually a rigid laminate with a stable dielectric constant. This helps in maintaining signal integrity and preventing signal loss. Materials like FR-4 and CEM-1 are commonly used for the core.

Considerations When Choosing Materials

Electrical Performance: Think about the electrical performance of your PCB board. Different materials have varying dielectric constants, which affect signal speed and quality. For high-frequency applications, you might need materials with low dielectric constants, such as Rogers materials. These can handle higher frequencies better than standard FR-4.

Thermal Management: PCBs often generate heat during operation. Good thermal management materials help dissipate this heat efficiently. For high-power applications, you may need materials with better thermal conductivity to prevent overheating and maintain board performance.

Cost vs. Performance: While high-quality materials can enhance performance, they often come with a higher price tag. It’s essential to balance your needs with your budget. FR-4 provides a good balance of performance and cost for many standard applications.

Environmental Factors: Consider the environment where the PCB will be used. If the board will be exposed to harsh conditions, like extreme temperatures or moisture, you’ll need materials that can withstand these environments. Choose materials that offer resistance to these factors to ensure the board’s longevity.

Final Tips for Selecting Materials

When selecting materials for your 4-layer PCB board, it’s essential to keep your specific requirements in mind. Evaluate the performance needs, environmental conditions, and budget constraints. Don’t hesitate to consult with PCB manufacturers or material suppliers for their expertise and recommendations. They can provide valuable insights and help you choose the best materials for your project.

The Ending NOTE

Choosing the right materials for a 4-layer PCB board involves understanding the different types of materials available and how they affect performance. By considering factors such as electrical performance, thermal management, and cost, you can make informed decisions that will lead to a successful and reliable PCB design!

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.