Industrial Chillers Price In Pakistan - Chiller House

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The Importance of Industrial Chillers in Modern Manufacturing

In today’s fast-paced industrial world, keeping equipment and processes cool is not just a preference, it's a necessity. This is where industrial chillers come in. These cooling systems are a vital part of many industries, helping to maintain safe temperatures, reduce downtime, and protect sensitive machinery from overheating.

Industrial chillers work by removing heat from a process or equipment and transferring it elsewhere, usually through the use of water or a water-glycol mixture. Whether it’s a plastic manufacturing plant, food processing facility, or pharmaceutical setup, chillers ensure that operations continue smoothly without heat-related interruptions.

Why Are Industrial Chillers So Important?

The role of an industrial chiller goes beyond just cooling. It ensures that every part of the production process remains stable and consistent. Overheating can lead to equipment failure, low product quality, and even total production shutdowns. With a properly functioning chiller, manufacturers can operate confidently and efficiently, knowing their machinery is protected.

In industries such as plastic injection molding or metal finishing, temperature control is crucial. A fluctuation of just a few degrees can impact the strength or finish of the final product. That’s why industrial chillers are often considered the backbone of any heat-sensitive process.

Types of Industrial Chillers

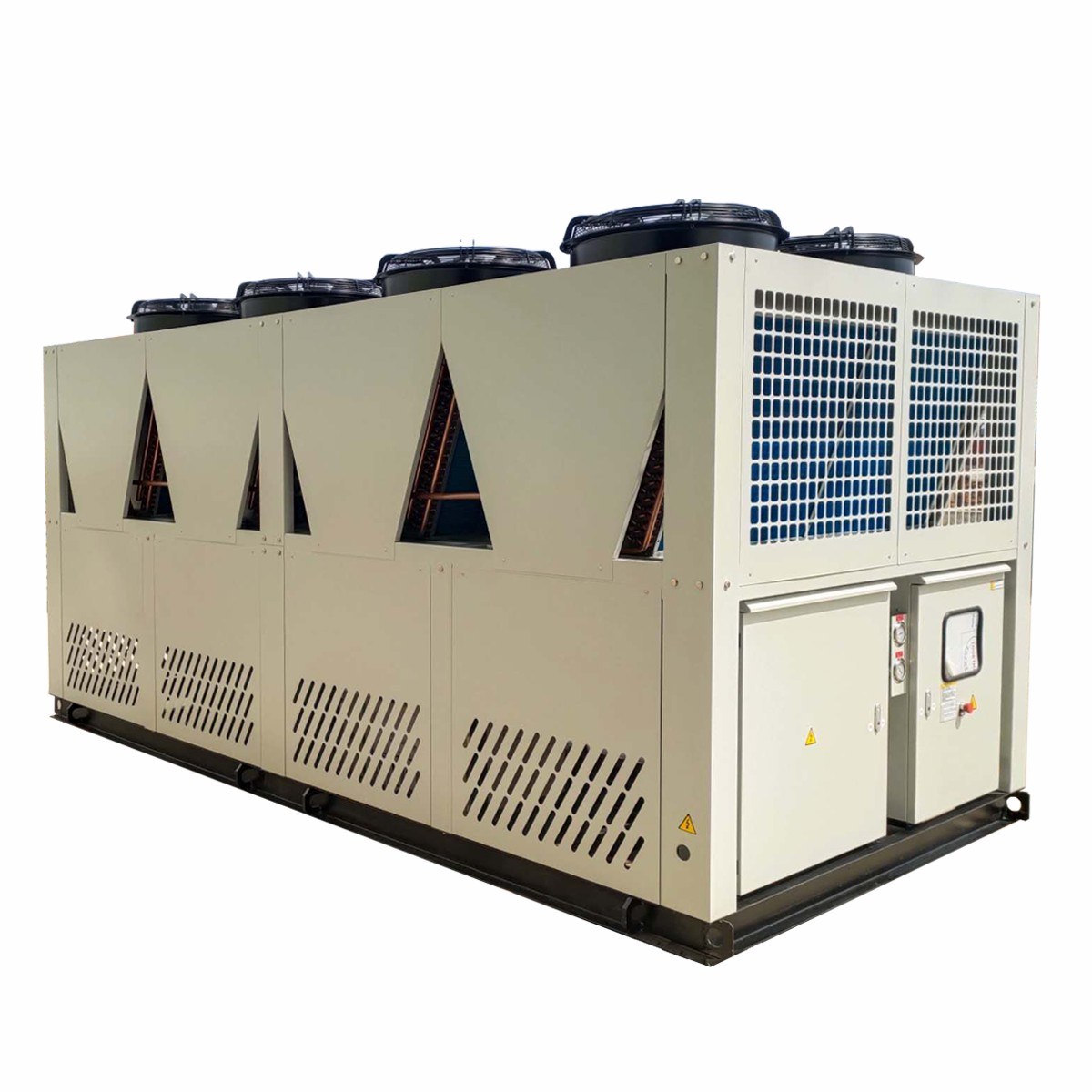

There are mainly two types of industrial chillers used today: air-cooled and water-cooled.

Air-cooled chillers use ambient air to remove heat and are often used in outdoor environments. They are easier to install and maintain but may not be as efficient in hotter climates.

Water-cooled chillers use a separate water source for heat exchange and are preferred for large-scale applications where efficiency and temperature stability are priorities.

Choosing the right type depends on the nature of your application, available space, and cooling requirements.

Energy Efficiency and Cost Savings

Modern industrial chillers are designed with energy efficiency in mind. Many newer models come equipped with variable speed compressors, advanced control panels, and eco-friendly refrigerants that help lower electricity costs while minimizing environmental impact.

For businesses, this translates to long-term savings and a better return on investment. The initial cost of a chiller may seem high, but the durability, efficiency, and performance they offer make them a smart financial decision in the long run.

Choosing the Right Chiller

When investing in an industrial chiller, factors such as cooling capacity, flow rate, environmental conditions, and energy consumption must be considered. Working with an experienced manufacturer or supplier can help ensure you get a system that’s tailored to your specific needs.

Final Thoughts

Industrial chillers are essential to maintaining the reliability and efficiency of manufacturing operations. As industries grow and technology advances, the demand for high-performance, energy-efficient cooling solutions continues to rise. By investing in the right industrial chiller, businesses can ensure smoother operations, better product quality, and significant cost savings over time.

Frequently Asked Questions About Industrial Chillers

1. What is an industrial chiller?

An industrial chiller is a cooling system designed to remove heat from equipment, processes, or materials in commercial and industrial settings. It circulates chilled water or glycol through a closed-loop system to maintain desired temperatures and prevent overheating.

2. What industries use industrial chillers?

Industrial chillers are used in a wide range of industries, including plastics, food and beverage, pharmaceuticals, HVAC, chemical processing, dairy, printing, and laser cutting. Any process that generates heat or requires temperature control can benefit from a chiller.

3. What’s the difference between air-cooled and water-cooled chillers?

Air-cooled chillers use fans to remove heat using ambient air, making them ideal for outdoor installations and smaller spaces. Water-cooled chillers use a water source and cooling tower, offering higher efficiency and better performance in large-scale or high-load operations.

4. How do I choose the right industrial chiller?

Choosing the right chiller depends on factors like cooling capacity, flow rate, temperature requirements, energy efficiency, environmental conditions, and installation space. It’s best to consult with a professional chiller manufacturer or supplier to get a system tailored to your needs.

5. Are industrial chillers energy-efficient?

Yes, modern industrial chillers are designed for energy efficiency. Many come with variable speed compressors, smart controllers, and eco-friendly refrigerants to reduce electricity consumption and operational costs.

6. How much does an industrial chiller cost in Pakistan?

The price varies depending on the type, capacity, and features. For the best industrial chiller house price in Pakistan, it's recommended to contact a reliable manufacturer like Chiller House for a customized quote.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.