Introduction to UV Printers

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Welcome to the world of UV printers! If this isn’t your first exposure to UV printers, then you know the limitless creative possibilities that UV printing offers to those looking to create new products and present them with a competitive advantage. If you’re new to UV printing, then your eyes are about to open wide! Malrem innovations have created powerful new ways to prepare and present cutting-edge products, while being friendly and easy to use and clean. UV printers can give any business or creative endeavour an edge. If you’re looking to accelerate product development, fulfil custom orders, produce truly unique gifts and art pieces, or enter the rewarding world of one-off manufacturing, UV printing is one of several solutions that can help you get there. We’ll briefly explore what makes the technology so special.

What is a UV Printer?

Definition and Explanation

A UV’s or ultraviolet printer uses UV light to cure or dry the ink as it is being printed. This is a great way to print on many different substrates. For example my UV printer can print on almost anything! A UV printer prints using UV light. The UV printer is a flexible machine that can print onto many different types of materials.

A normal ink jet printer uses heat to ‘trap’ the ink and air to dry up the ink whereas with a UV printer the UV light instantly cures the ink.

How UV Printers Work

UV printers have light sources that emit UV light to cure the ink as it is deposited on the print medium. The UV light source travels behind the print head, curing immediately as the ink is deposited. The resulting film result is very durable, quick-drying ink. The cured ink is a layer on top of the surface medium, which means it can be printed on nearly any material, without absorption issues.

Benefits of Using UV Printers

Versatility in Printing

The versatility of UV printers is a highly celebrated perk of the technology: you can print almost anything, including on almost any material – wood, glass, metal, plastic, even fabric – for just about any industry or use that you can think of.

Speed and Efficiency

One of the advantages of UV printers is they are very quick to use. Once the image has been exposed, UV curing takes place instantaneously, and so the whole process is quicker than with other, more traditional methods of printing. This means that businesses can meet deadlines more efficiently, and when dealing with higher volumes, getting things done faster is imperative.

Durability and Quality

Another advantage for UV printers is their ability to print durable prints. The ink used by UV printers is UV-cured, which is scratch-resistant and doesn't fade or rub off, regardless of the material it's printed on. Besides having a longer lifetime, UV printed signs can be used in a wide range of environments both indoors and outdoors.

Types of UV Printers

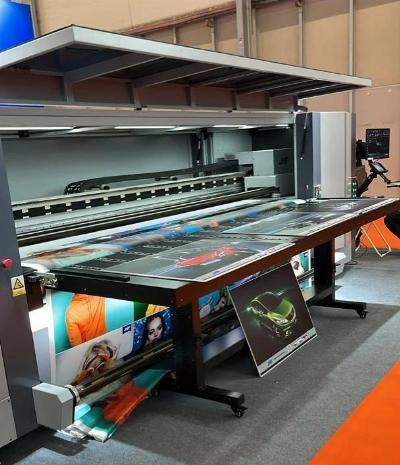

Flatbed UV Printers

One way is with flatbed UV printers, where the print head moves over a stationary bed and the material to be printed on is placed on the bed. This method enables flatbed UV printers to create highly accurate, detailed images. The other principle is roll-to-roll UV. Here, the print head moves, just like in inkjet printing, and the material being printed onto is fed through the printer on a roller. These provide flexibility and are used in applications such as printing on plastic film to produce flexible packaging materials, labels for car windscreens, bottle wrapping and more. UV roll-to-roll printers account for more than three-quarters of the functional ink print and decoration market.

Features of Flatbed Printers

Flatbed UV printers are capable of extremely high resolution and can be used to print on thick and/or uneven surfaces. They’re also a natural fit, as software, memory and powerful ‘print heads’ – the machines that actually lay down the ink – become the factors that determine how fast they can work. As a result, they are likely to be fitted with a vacuum bed to hold the material in place, as well as four or more print heads.

Common Uses of Flatbed Printers

Nowadays, these printers can produce full-colour signage, art, decor and many industrial components from virtually any material. Really, the possibilities appear endless.

Roll-to-Roll UV Printers

They are designed for flexible materials supplied on rolls rather than flat sheets, which load into the roll gap at the rear of the machine and exit in roll form – think of banners and vinyl. As a result, they are also good for larger volumes of print (rather than one-off customised bits). This makes this type of UV printer particularly popular for use in producing banners, vehicle wraps and large-format graphics.

Features of Roll-to-Roll Printers

These printers feature long material feed systems that are designed not only to prevent materials from jamming but also to properly tension them over hundreds of metres of print width. These are incomparable to inkjet printers due to their high speed, which makes them suitable for very large print runs.

Common Uses of Roll-to-Roll Printers

These durable, high-quality banners, vehicle-wraps and large-format prints are commonly produced by roll-to-roll printers. They are highly productive, creating amazing images, and have been widely used in the advertising and market industry. For more information visit Canon, a world leader in imaging solutions.

Hybrid UV Printers

These hybrid UV printers share the desirable characteristics of both flatbed UV and roll-to-roll UV printers: the ability to work on both rigid and flexible materials. With the performance of flatbeds combined with unmatched throughput of roll-to-roll systems, hybrid printers are suitable for everything from custom branded promotional products to large-format displays.

Features of Hybrid Printers

Hybrid printers have adjustable beds that switch between flatbed and roll-to-roll modes, can be configured according to a particular application, and have many print heads for fast, precise printing.

Common Uses of Hybrid Printers

These models are often used by industrial manufacturers and the production of signs, packaging, and custom promotional products. Their machines allow for printing on both hard and soft substrates.

Applications of UV Printers

Printing on Various Materials

Another facet of this capability is the ability of the UV printers to print on nearly any surface you can think of. Anything from promotional items to packaging and custom gifts can be produced and delivered with near endless possibilities in terms of the creative and functional nature of the surface. This makes the technology a perfect fit for customers in any sort of industry who require quality, durable and reproducible prints on non-traditional materials.

Industrial Applications

UV technology plays an important role in the industrial area. For example, UV printers are used in printing of components, labels and packaging, for example on industrial components that often are not porous.Printing with UV in industrial applications does not only applied on porous materials. The main advantage that advantage of UV (compared to for example screen printing) is that the prints remains durable also in dry conditions or rough environments.

Creative and Artistic Uses

By using UV printers, artists and designers are creating custom art and graphics on previously unobtainable or low-quality products. With UV printers, we are finally printing on unconventional surfaces, merging art and design in radical new ways. Vibrant colours and extraordinary detail make UV printing popular with graphic design professionals.

Choosing the Right UV Printer

Factors to Consider

Choosing a UV printer depends on the type of material you want to print on, how many prints you need to do, and the level of detail you require.

Budget and Cost

UV printers range from several hundreds of pounds to several tens of thousands. However, you have to balance your budget with the printer’s features and your business needs. The initial outlay may be considerable, but the long-term advantages of UV printing often make it worth it.

Technical Specifications

Take a look at the printer’s technical specifications, including its print speed (how quickly it can print), its print resolution (the clarity of the images), and the kinds and number of ink cartridges it uses. These will all affect the quality and speed of your prints, and being aware of this will help you make the best buying decision.

Maintenance and Care for UV Printers

Routine Maintenance Tips

It is very important to keep your UV printer well maintained. You must clean the print heads of ink in the machine, you must check how much ink is left, and especially you must make sure that the UV lamps are working properly for the best results.

Common Issues and Troubleshooting

Don’t forget to check on problems with ink clogging, curing issues and so on. It’s handy to have a resource of troubleshooting steps or a support team that can save you money in downtime. You’ll notice issues sooner if you’re vigilant, and you’ll save yourself from stressful, unexpected outages that have a potentially negative impact on your company.

. Be aware of a printer’s lifespan and its effect on efficiency Often, your motivation for preserving printer efficiency will become financial. Upkeep of a printer can cost more than purchases. As the cost of older inkjet printers rises, the value of efficient monochrome laser printers can skyrocket.

Future Trends in UV Printing

Technological Advancements

As technology improves, manufacturers are adding features to make UV printers run faster, use different substrates and inks, and enabling numerous new applications for UV printing.

Market Growth and Opportunities

The market size could grow fast driven by exploding demand for high-quality picture production with UV printers. This demand offers tons of opportunities for companies to enter new markets and strengthen the production base of the printing field.

Conclusion

UV printers have arrived, and now you can have custom print jobs in any shape, on anything, at the speed of now and basically forever. Regardless of whether you’re a manufacturer, an artist or a marketing communications professional, investing in a UV printer could dramatically improve the look and feel of all your printing projects. The reality is that, at the rate that media and technology are changing, UV printers offer capabilities that consistently move the needle forward.

FAQs

What materials can a UV printer print on?

UV printers are also being used to directly print into durable and unbreakable plastic as well as metal, hard and soft plastic, glass, wood and fabric, all using their UV curing technology.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.