Machine Condition Monitoring Market 2024: An Evolving Landscape

The machine condition monitoring market is experiencing significant growth in 2024, driven by the increasing need for predictive maintenance and the adoption of advanced technologies across various industries. Condition monitoring, the process of tracking a machine's performance and health, has become critical in ensuring operational efficiency, minimizing downtime, and reducing maintenance costs.

Rising Demand for Predictive Maintenance

As industries worldwide strive to enhance productivity and reduce operational costs, predictive maintenance has emerged as a key strategy. By continuously monitoring the health of machinery, companies can predict potential failures and perform maintenance before issues escalate, thereby avoiding costly unplanned downtime. This proactive approach is gaining traction across sectors such as manufacturing, energy, oil and gas, and transportation.

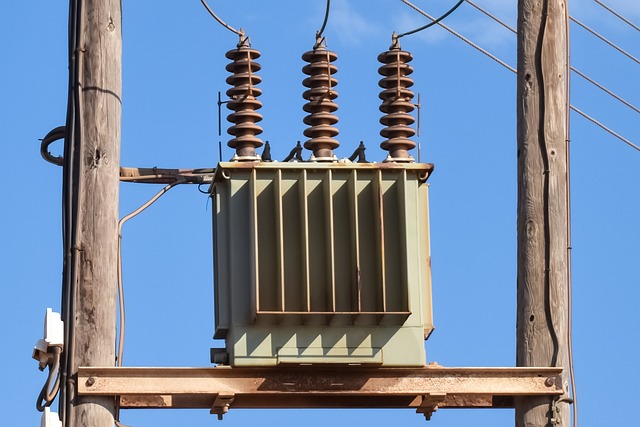

Adoption of IoT and IIoT Technologies

The integration of Internet of Things (IoT) and Industrial Internet of Things (IIoT) technologies is transforming the machine condition monitoring landscape. These technologies enable real-time data collection and analysis, providing valuable insights into machine performance. The ability to monitor machinery remotely and in real-time is particularly beneficial for industries with complex and distributed operations. In 2024, the continued adoption of IoT and IIoT is expected to drive the growth of the machine condition monitoring market, as companies leverage these technologies to enhance predictive maintenance strategies.

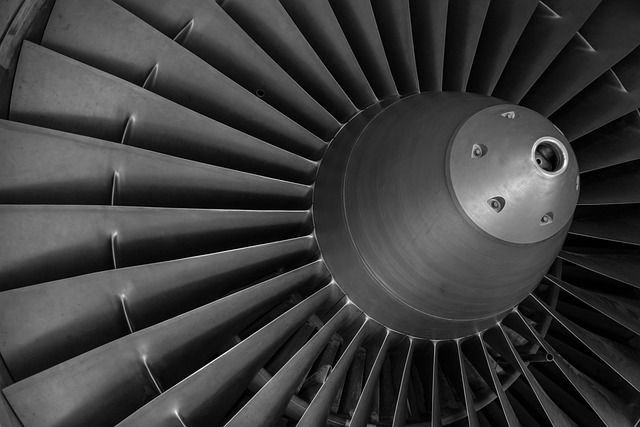

Emergence of Advanced Sensors and Data Analytics

Advanced sensors and data analytics are at the forefront of the machine condition monitoring market's evolution. Sensors have become more sophisticated, capable of capturing a wide range of data points such as vibration, temperature, and pressure. Coupled with advanced analytics, this data is processed to detect anomalies and predict potential failures with greater accuracy. The rise of machine learning and artificial intelligence in data analytics is further enhancing the effectiveness of condition monitoring systems, enabling more precise and actionable insights.

Challenges and Opportunities

Despite the promising growth, the machine condition monitoring market faces challenges. The high initial investment required for implementing advanced condition monitoring systems can be a barrier for small and medium-sized enterprises. Additionally, the complexity of integrating new technologies with existing systems can pose difficulties for some organizations.

However, these challenges also present opportunities for innovation. Companies that can offer cost-effective and easy-to-integrate solutions are likely to find success in this evolving market. Moreover, as industries become increasingly aware of the long-term benefits of condition monitoring, the demand for these solutions is expected to rise, further fueling market growth.

For More Info https://www.gmiresearch.com/report/machine-condition-monitoring-market/

Conclusion

In 2024, the machine condition monitoring market is poised for continued expansion as industries embrace predictive maintenance, IoT, and advanced analytics. While challenges exist, the potential benefits of improved operational efficiency and reduced downtime are driving widespread adoption. As technology continues to advance, the machine condition monitoring market is set to play a critical role in the future of industrial operations.

While challenges exist, the potential benefits of improved operational efficiency and reduced downtime are driving widespread adoption. As technology continues to advance, the machine condition monitoring market is set to play a critical role in the future of industrial operations.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.