Maintenance Tips to Maximize the Life of Your Planetary Gearbox

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

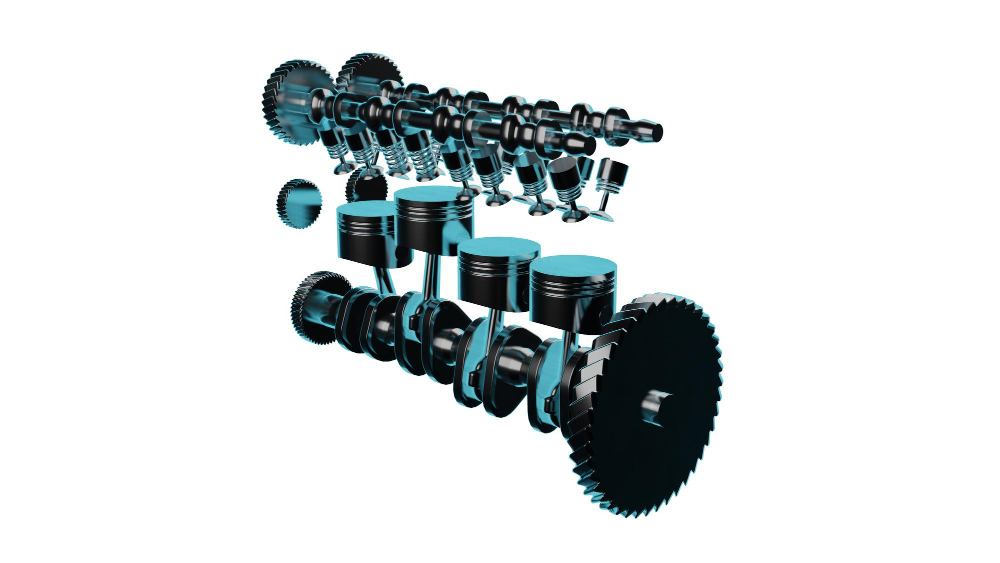

A planetary gearbox is a workhorse in many industrial applications—from robotics and automotive systems to heavy machinery and aerospace equipment. Known for their compact size, high torque density, and durability, these gearboxes are essential for smooth and reliable motion control. However, like all mechanical systems, planetary gearboxes require regular maintenance to ensure optimal performance and to extend their service life.

In this guide, we’ll share practical and proven maintenance tips to help you get the most out of your planetary gearbox.

Why Maintenance Matters

Before diving into specific tips, it’s important to understand why maintenance is non-negotiable.

Neglecting maintenance leads to:

- Increased wear and tear

- Loss of efficiency

- Unexpected breakdowns

- Costly downtime and repairs

Regular checks and preventive care reduce operating costs, improve productivity, and maximize the lifespan of your investment.

1. Regularly Check Lubrication Levels

Lubrication is the lifeblood of any gearbox. Proper lubrication reduces friction, minimizes wear, and prevents overheating.

What to do:

- Check lubricant levels as per the manufacturer's schedule (weekly or monthly).

- Use only manufacturer-recommended oil or grease.

- Replace the lubricant if it appears discolored, milky, or gritty—signs of contamination or degradation.

Pro Tip:

High-performance planetary gearboxes often require synthetic oils with excellent thermal stability and anti-wear properties. Don’t compromise on quality.

2. Keep It Clean

Dust, dirt, and grime can accumulate around the gearbox and slowly make their way inside, leading to contamination.

What to do:

- Wipe down external surfaces regularly.

- Ensure that seals and gaskets are intact to prevent foreign particles from entering.

- For outdoor gearboxes, consider protective covers or enclosures.

- Clean environments equal longer-lasting components.

3. Monitor Temperature

Excessive heat is a major enemy of mechanical parts, especially in high-speed or high-torque applications.

What to do:

Monitor gearbox operating temperature with thermal sensors or infrared guns.

If the gearbox runs hotter than recommended, it could signal:

- Overloading

- Poor lubrication

- Misalignment

- Address the issue promptly to prevent internal damage.

A well-maintained gearbox should operate within the normal temperature range specified by the manufacturer.

4. Listen for Unusual Noises

Gearboxes in good health are relatively quiet. Unusual sounds—grinding, whining, or clunking—are early signs of trouble.

What to do:

- Conduct routine sound checks while the machine is running.

- Note any changes in pitch, vibration, or noise patterns.

- Investigate and troubleshoot early. These sounds may indicate bearing wear, gear misalignment, or insufficient lubrication.

Trust your ears—they're one of your best diagnostic tools.

5. Inspect Shaft Alignment and Mounting

Misalignment puts uneven stress on gears, shafts, and bearings, significantly shortening the lifespan of your gearbox.

What to do:

- Regularly check alignment between the gearbox and connected machinery.

- Ensure bolts and fasteners are secure and that the base is stable.

- Use dial indicators or laser alignment tools for precision.

- Correct alignment ensures smooth torque transmission and reduces wear.

6. Perform Vibration Analysis

Vibration is a common early indicator of gearbox problems such as imbalance, looseness, or gear damage.

What to do:

- Conduct routine vibration analysis using portable devices or condition-monitoring systems.

- Compare readings over time to detect changes or trends.

- Investigate any spikes or irregularities.

- Predictive maintenance saves money by addressing issues before failure occurs.

7. Replace Seals When Necessary

Seals prevent lubricant leaks and block contaminants. A failed seal can lead to major damage if not addressed in time.

What to do:

- Inspect seals for wear, cracks, or leaks.

- Replace seals during scheduled maintenance—don’t wait for failure.

- Always use compatible, high-quality seals.

An inexpensive seal replacement now can save you from replacing an entire gearbox later.

8. Avoid Overloading the Gearbox

Overloading can cause teeth to chip, bearings to fail, and heat to build up—leading to a catastrophic breakdown.

What to do:

Follow the gearbox's rated torque and load capacity strictly.

- If your application has frequent start-stop cycles or shock loads, consider using a torque limiter.

- Upgrade your gearbox if operational demands exceed its limits.

- Always match the gearbox to the application. Bigger isn’t always better, but “just enough” isn’t either.

9. Schedule Preventive Maintenance

Don’t wait for something to go wrong. Proactive maintenance saves you time, money, and frustration.

What to do:

- Create a preventive maintenance schedule based on usage and environmental conditions.

- Log inspections, oil changes, and component replacements.

- Train your team to recognize early signs of wear or damage.

- Consistency is key—set a routine and stick to it.

10. Partner With Your Gearbox Manufacturer

Manufacturers offer valuable support, including maintenance guides, replacement parts, and expert consultations.

What to do:

- Refer to the user manual for specifications, torque ratings, and recommended maintenance.

- Use genuine spare parts to ensure compatibility and performance.

- Contact technical support if you're unsure about symptoms or repairs.

Building a long-term relationship with your gearbox supplier helps keep your equipment running smoothly.

Bonus Tip: Upgrade When It Makes Sense

Even with the best maintenance practices, gearboxes eventually wear out or become outdated. If your gearbox is struggling to meet your current demands, it may be time for an upgrade.

- Modern planetary gearboxes offer:

- Improved energy efficiency

- Higher torque capacities

- Compact and lightweight designs

- Smart monitoring features

Consult with an expert to evaluate whether a new gearbox could enhance your system's performance and reliability.

Final Thoughts

Planetary gearboxes are built for strength, efficiency, and reliability—but only if they’re treated with the care they deserve. By following the tips outlined above, you can extend the life of your gearbox, reduce downtime, and improve your equipment’s overall performance.

Whether you operate in automation, manufacturing, mining, or renewable energy, regular maintenance is your best strategy for protecting your investment.

Need help choosing the right lubricant? Wondering if it's time for a replacement? Reach out to your gearbox provider for expert advice tailored to your application.

Keep your planetary gearbox running like clockwork—because when your gearbox runs smooth, your business runs better.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.