Why Your Motion Control System Fails Without a Quality Servo Drive

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

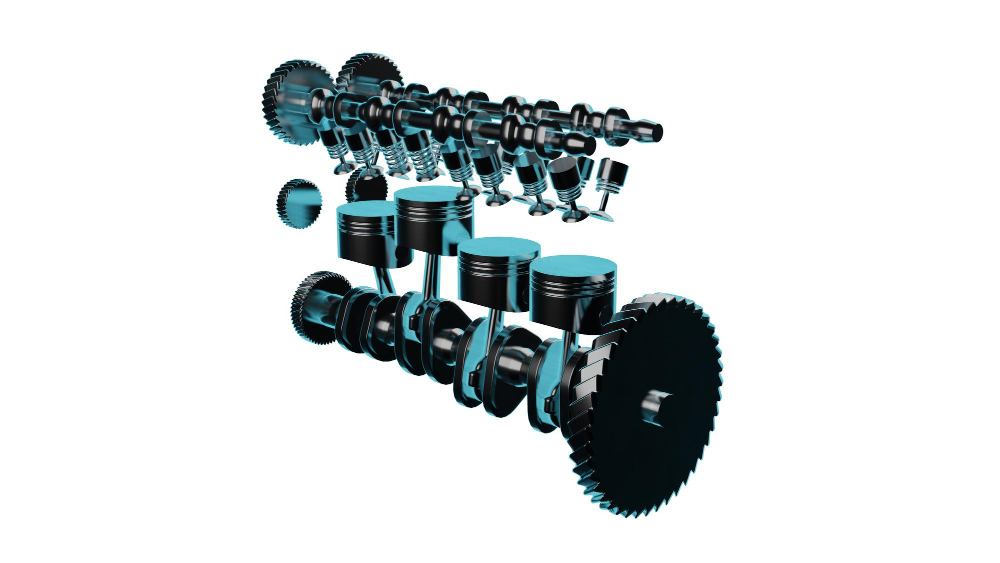

When it comes to automation and precision machinery, motion control systems are the heart of many industries—robotics, packaging, manufacturing, CNC machines, and beyond. These systems are engineered to move mechanical parts with accuracy and speed. But there’s one essential component that often determines their success—or failure: the servo drive.

Think of the servo drive as the brain-to-muscle connection of your machine. It interprets commands from the control system and delivers power to the motor with precise timing and regulation. If your servo drive isn't up to par, it’s not just an inconvenience—it can bring your entire system down.

Let’s explore why your motion control system is at risk without a quality servo drive, and what makes investing in the right one so critical.

1. Servo Drives Are the Power Translators

At its core, a servo drive takes low-level command signals from a controller (like position or speed data) and turns them into high-power voltage and current that can move a servo motor precisely.

Without a quality drive, these signals can get lost, distorted, or delayed. That leads to inaccurate movement, motor instability, or even damage.

A high-quality servo drive ensures:

- Accurate motor response

- Stable torque and speed control

- Smooth operation with minimal vibration

- Efficient energy use

Without it? Expect jerky movements, missed positions, and system errors.

2. Precision and Repeatability Depend on It

Whether you’re cutting materials, assembling electronics, or operating a robotic arm—precision matters. Motion control systems are often expected to perform tasks within tight tolerances, again and again.

A quality servo drive delivers the repeatability you need by:

- Minimizing drift and deviation

- Enabling real-time feedback adjustment

- Supporting high-resolution encoders and sensors

Poor servo drives introduce delays, inaccuracies, and inconsistencies. In the long run, this affects your product quality and production efficiency.

3. Inferior Drives Cause Downtime and Failures

If your servo drive can’t keep up with your system’s demands, it becomes a bottleneck—or worse, a failure point.

Low-grade or mismatched drives tend to:

- Overheat under load

- Struggle with sudden speed or direction changes

- Cause noise or interference

- Fail prematurely under continuous use

Downtime caused by servo drive failure can be expensive—not just in repair costs, but in lost productivity and deadlines missed.

A quality servo drive, built with proper heat dissipation, overload protection, and compatibility, can run reliably for years under demanding conditions.

4. Energy Efficiency Starts with the Drive

Servo drives play a critical role in regulating power to the motor. An efficient drive reduces power consumption during idle times, controls acceleration smoothly, and prevents energy spikes during operation.

Over time, using an energy-efficient servo drive translates to:

- Lower electricity bills

- Reduced heat generation

- Less strain on the motor and system components

- A greener, more sustainable operation

If you’re scaling production or operating around the clock, these savings add up fast.

5. Modern Drives Offer Smart Features for Smarter Control

Today’s high-performance servo drives come loaded with features like:

- Real-time monitoring and diagnostics

- Integrated safety functions (STO, SS1, etc.)

- Auto-tuning for optimized motor performance

- Network compatibility (EtherCAT, CANopen, Modbus, etc.)

These features don’t just make your system more efficient—they give you greater control, faster troubleshooting, and flexibility to scale or modify your system in the future.

If you're still using basic or outdated servo drives, you're missing out on valuable tools that modern automation requires.

6. Your Entire System Depends on It

Your motion controller might be cutting-edge. Your mechanical design might be perfect. But if the servo drive isn't performing at the same level, your system will underperform—or fail entirely.

This is especially true in applications like:

- CNC machining – where a millimeter of error can ruin a job

- Robotics – where smooth, coordinated motion is vital

- Printing and packaging – where speed and precision go hand-in-hand

- Semiconductor production – where cleanliness, accuracy, and repeatability are non-negotiable

In each of these scenarios, a subpar drive leads to defects, misalignment, wasted material, and customer dissatisfaction.

7. You Can’t Afford the Hidden Costs of a Bad Drive

Some businesses try to save money by purchasing budget drives or using mismatched hardware. While the initial cost may be lower, the hidden costs tell a different story:

- More frequent maintenance

- Higher rejection rates

- Missed production targets

- Reduced machine lifespan

- Increased energy costs

The right servo drive may cost more upfront—but it quickly pays for itself in reliability, performance, and long-term savings.

How to Choose the Right Servo Drive

When selecting a servo drive, consider the following:

- Motor compatibility – Ensure it matches the power, torque, and feedback requirements

- Application demands – Choose a drive that can handle load variations and acceleration needs

- Environment – Consider temperature, dust, and vibration resistance

- Communication protocols – Ensure it integrates with your existing control system

- Safety features – Built-in protections are essential for both equipment and operator safety

Partnering with a trusted servo drive supplier or manufacturer also helps ensure technical support and service if issues arise.

Final Thoughts: Don’t Let a Weak Link Break the Chain

A motion control system is a beautifully complex orchestra of hardware and software—each piece playing a vital role. And among those, the servo drive is one of the most critical components.

When you invest in a high-quality servo drive, you invest in the precision, reliability, and efficiency of your entire operation.

So, before you blame your motor, your controller, or your mechanical design for system issues, ask yourself:

Is your servo drive holding everything back?

Because without the right drive, your motion control system is like a race car with a faulty engine—destined to fall short, no matter how polished it looks.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.