Membrane Reactor: A Smart Integration of Reaction and Separation

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

A membrane reactor is an advanced chemical processing unit where reaction and separation occur simultaneously in a single step. This integration allows better control over reaction pathways, improved conversion rates, and reduced energy requirements. I3 Nanotec, an Indian process engineering company, develops and supplies reliable membrane-based technologies that help industries optimize complex reactions and downstream separation tasks. Combining practical design, robust materials, and application-focused engineering, I3 Nanotec supports high-performance systems for use in pharmaceutical, chemical, and petrochemical manufacturing.

Traditional reactors typically require multiple stages, involving a reaction step followed by separation units such as distillation, extraction, or adsorption. In contrast, membrane reactors minimize these needs by allowing specific products or by-products to pass through the membrane barrier while the reaction is ongoing. This creates a continuous driving force that can shift the chemical equilibrium toward the desired outcome, resulting in higher yields and improved process economics.

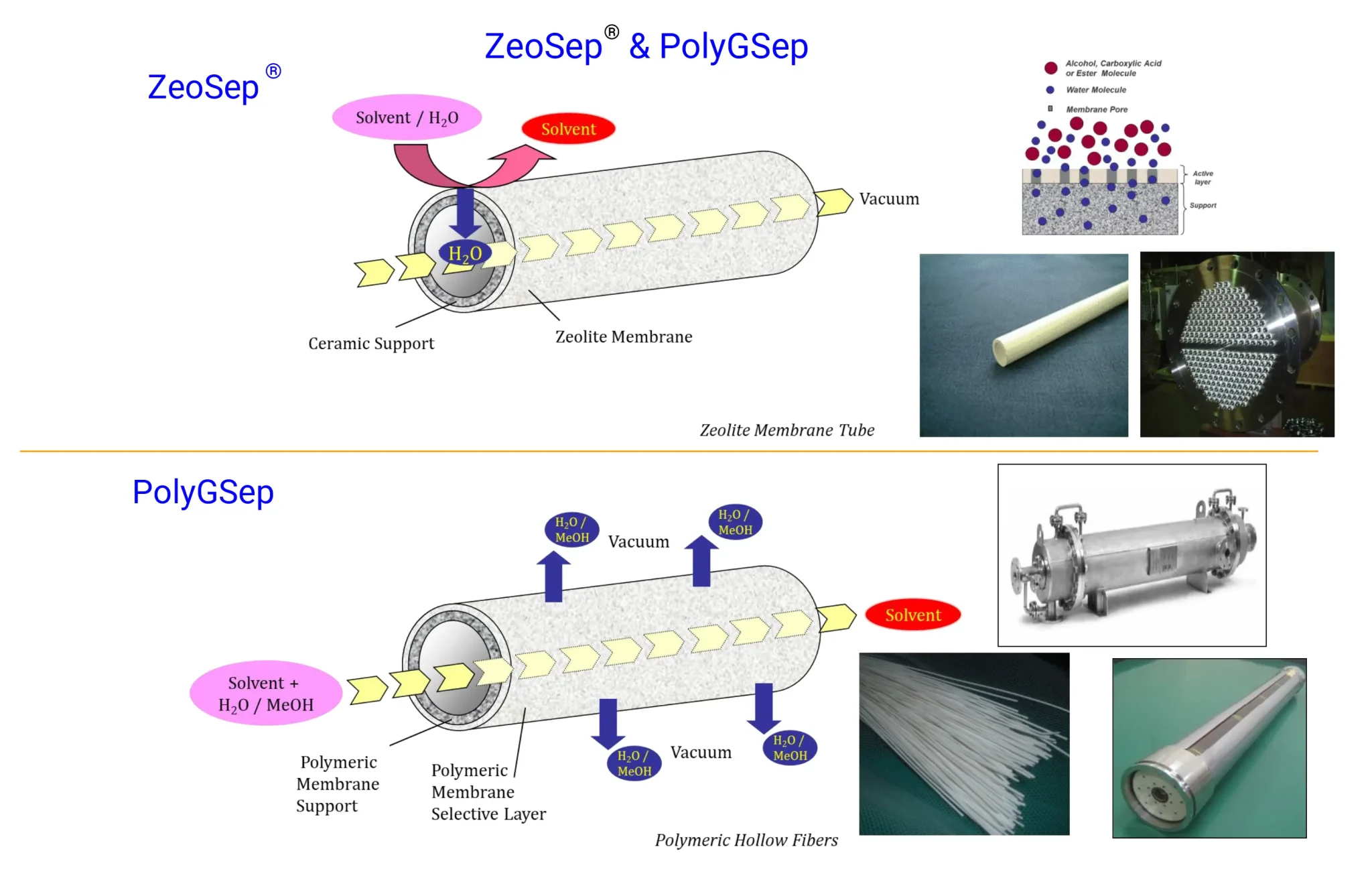

The core advantage of using a membrane reactor lies in its ability to perform selective separation alongside the reaction. Depending on the process requirements, separation methods such as vapor permeation or pervaporation can be integrated within the membrane system. These techniques are especially valuable when dealing with azeotropic mixtures, close-boiling components, or solvents that are difficult to separate by conventional means.

Vapor permeation is ideal for separating components from vapor-phase mixtures, particularly useful in organic-organic or organic-water systems. It works under moderate temperature and vacuum conditions, significantly lowering thermal energy consumption. Pervaporation, on the other hand, handles liquid-phase mixtures where one component preferentially diffuses through the membrane and evaporates on the permeate side. Both techniques offer energy-efficient alternatives to thermal separation, especially when combined within a membrane reactor.

At the heart of these systems lies the zeolite membrane, a highly selective and stable material known for its microporous crystalline structure. Zeolite membranes provide strong chemical resistance, thermal stability, and molecular-level separation capability. These properties are essential when integrating the membrane directly into a reactive system, where pressure, temperature, and solvent compatibility are critical considerations.

I3 Nanotec leverages its experience with zeolite membrane fabrication and application-specific membrane selection to build durable membrane reactor systems. Each reactor is configured based on the kinetics of the target reaction, operating pressure, temperature limits, and feed composition. This results in a system that not only improves yield but also reduces energy input and downstream load, enabling faster processing times and improved operational control.

Applications of membrane reactors are diverse and expanding. In esterification processes, for example, water generated during the reaction can be continuously removed through pervaporation, driving the reaction forward and enhancing conversion. In dehydrogenation reactions, hydrogen gas can be selectively extracted through vapor permeation, reducing its inhibitory effect and enhancing productivity. These examples illustrate how membrane reactors can be tailored for specific reactions to deliver measurable benefits in both batch and continuous operations.

I3 Nanotec’s approach goes beyond supplying equipment. The company works closely with industrial partners to assess feasibility through pilot trials, select appropriate membranes, and design fully integrated systems. Each stage—from concept to commissioning—is supported by detailed process evaluation, material compatibility checks, and performance validation to ensure alignment with production goals and regulatory standards.

The use of membrane reactors also supports long-term sustainability efforts by reducing waste, minimizing solvent loss, and lowering energy demands. By removing the need for energy-intensive steps like distillation or solvent stripping, membrane-integrated systems offer practical solutions for meeting environmental targets and operational budgets. This is particularly beneficial for sectors under increasing regulatory pressure to reduce emissions and optimize resource usage.

I3 Nanotec’s membrane reactors are designed to be compact, modular, and scalable. This allows easy integration into existing plants or expansion of capacity without major redesign. Industries looking to improve throughput, reduce downtime, and enhance product quality find significant value in adopting membrane reactor technology.

If your production process requires efficient reaction and precise separation within a single system, membrane reactors offer a smart and reliable approach. Combined with technologies such as pervaporation, vapor permeation, and robust zeolite membranes, they present a modern solution for process intensification.

The use of zeolite membranes in these systems enhances selectivity and durability. Known for their crystalline microporous structure and resistance to heat and solvents, zeolite-based configurations enable precise molecular separation under varied pressure and temperature conditions. Their stability makes them ideal for hybrid systems where both reaction and separation occur under demanding environments.

Reach out to I3 Nanotec to explore how membrane reactors can help optimize your chemical processes, reduce energy consumption, and improve product consistency—all within a customized, technically sound framework.

https://www.i3nanotec.com/pervaporation/

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.