Vapor Permeation – A Simple Guide by i3nanotec

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

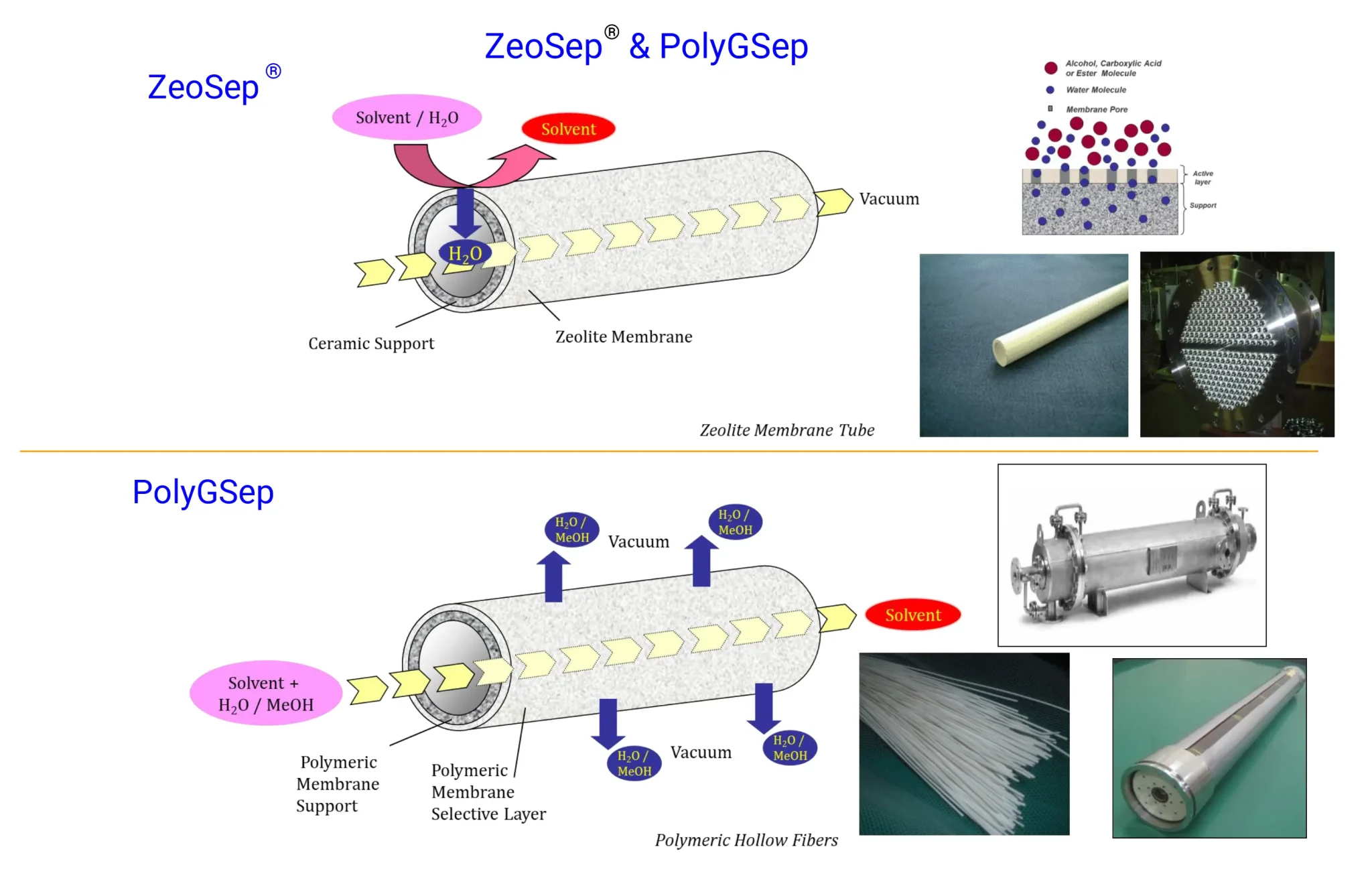

In many industries today, separating chemicals or purifying liquids is a big part of the process. One of the advanced and useful methods for doing this is vapor permeation. If you are in a field like chemical manufacturing, bio-processing, or solvent recovery, you may have already come across this term. At i3nanotec, we focus on making this process easier to understand and apply through our membrane-based technologies.

This article gives you a simple guide to what vapor permeation is, how it works, where it is used, and how i3nanotec is helping companies use it for better results.

What is Vapor Permeation?

Vapor permeation is a membrane-based separation process. It is used when you need to separate or purify vapors (gases or steam). In this method, a special membrane is used to allow certain parts of the vapor mixture to pass through it while keeping others behind.

Think of it like a sieve for vapors. The membrane lets specific vapor molecules go through and blocks others. This method is very useful when dealing with mixtures of water and solvents, or different organic solvents.

How Does Vapor Permeation Work?

Here’s a simple step-by-step look at how vapor permeation works:

Feed vapor: A vapor mixture is passed over a special membrane.

Separation: The membrane is selective. It allows certain molecules (like water or specific solvents) to pass through.

Permeate side: The molecules that pass through are collected on the other side.

Retentate side: The remaining part of the mixture stays on the feed side.

This process happens without the need for chemicals or high energy. It’s simple, clean, and efficient.

Where is Vapor Permeation Used?

Vapor permeation is used in many applications. At i3nanotec, we help companies use it for tasks such as:

1. Solvent Recovery

Many factories use organic solvents in their processes. After use, these solvents can be recovered and reused instead of throwing them away. Vapor permeation makes this recovery possible by separating solvents from water or other mixtures.

2. Ethanol Dehydration

Removing water from ethanol is important in many industries, especially in fuel and pharmaceutical sectors. Traditional methods use distillation, which takes a lot of energy. Vapor permeation is a more energy-saving option. Our zeolite membrane is perfect for this task because it allows water vapor to pass while holding back ethanol.

3. Peptide Purification

In biopharmaceutical work, separating peptides and purifying them is a common need. Membrane-based vapor permeation provides a gentle and precise way to do this, protecting sensitive molecules while still doing the job.

4. Organic Solvent Nanofiltration (OSN)

While vapor permeation works with vapors, OSN works with liquids. At i3nanotec, we use both methods to provide full solutions. OSN is great for purifying, concentrating, or separating valuable products from organic solvents.

What is Special About Zeolite Membranes?

At i3nanotec, we use zeolite membranes for many vapor permeation tasks. Zeolites are tiny crystal-like materials with pores that are just the right size to separate small molecules like water from ethanol. These membranes are:

Highly selective

Stable at high temperatures

Resistant to solvents

This makes them ideal for tough industrial jobs like ethanol dehydration or solvent recovery.

What is the Difference Between Vapor Permeation and Pervaporation?

You might hear the word pervaporation and wonder if it’s the same as vapor permeation. They are similar, but not exactly the same.

In pervaporation, the liquid feed is first in a liquid state. It touches the membrane directly and then evaporates through it.

In vapor permeation, the feed is already in vapor form before it touches the membrane.

Both processes are used to separate similar types of mixtures, but the setup and conditions are a bit different. At i3nanotec, we provide solutions for both.

Why Choose i3nanotec?

At i3nanotec, our goal is to make advanced separation technologies simple and practical. We design, build, and support membrane systems for industries of all sizes. Here’s what sets us apart:

We specialize in zeolite membranes that are highly efficient for vapor permeation.

We understand real industrial needs—like solvent recovery, peptide purification, and ethanol dehydration.

Our team provides full support from selecting the right membrane to setting up and running your system.

We combine technologies like OSN, pervaporation, and vapor permeation for the best results.

Final Thoughts

Vapor permeation is a smart and efficient way to separate vapor mixtures. It saves energy, reduces waste, and works well in many industries. Whether you are working with solvent recovery, ethanol dehydration, or peptide purification, vapor permeation can make your process better.

At i3nanotec, we are ready to help you apply this technology in a simple and cost-effective way. We bring the latest membrane technology, including zeolite membranes and OSN, into your process so you can meet your goals without complexity.

Contact us at i3nanotec today if you’d like to learn how vapor permeation can work for your needs.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.