Plant Asset Management Market Growth, Trends and Opportunity 2024-2032

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

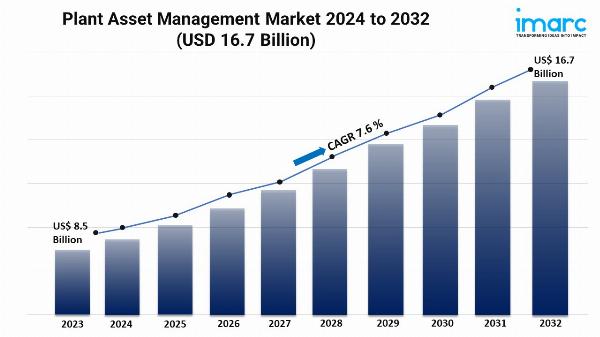

Global Plant Asset Management Market Statistics: US$ 16.7 Billion Value by 2032

Plant Asset Management Industry

Summary:

The global plant asset management market size reached USD 8.5 Billion in 2023.

The market is expected to reach USD 16.7 Billion by 2032, exhibiting a growth rate (CAGR) of 7.6% during 2024-2032.

North America leads the market, accounting for the largest plant asset management market share.

Services account for the majority of the market share in the offering segment due to the growing demand for specialized expertise and maintenance support.

Cloud-based holds the largest share in the plant asset management industry.

Production asset (motors, rotating, reciprocating equipment, process and mechanical equipment, and remote equipment, wiring and other electrical equipment) remains a dominant segment in the market.

Energy and power represent the leading end user segment.

The growing emphasis on predictive maintenance strategies is a primary driver of the plant asset management market.

Regulatory compliance and safety standards are reshaping the plant asset management market.

Request for a sample copy of this report: https://www.imarcgroup.com/plant-asset-management-market/requestsample

Industry Trends and Drivers:

Rising Focus on Predictive Maintenance:

The growing emphasis on predictive maintenance strategies is offering a favorable market outlook. By leveraging advanced technologies like artificial intelligence (AI), machine learning (ML), and the industrial internet of things (IIoT), businesses are increasingly moving towards proactive asset management. Predictive maintenance assists in forecasting equipment failures before they occur, thereby minimizing downtime and reducing costs associated with unexpected breakdowns. This shift is especially important in industries, such as manufacturing, oil and gas, and energy, where unplanned downtime can have significant financial and operational impacts. Companies are thus investing in plant asset management solutions to ensure continuous, optimized performance and to extend the lifespan of their machinery and equipment.

Increasing Adoption of Industrial IoT (IIoT):

The integration of IIoT is propelling the market growth. IIoT connects various physical assets, equipment, and systems to a centralized platform, allowing for real-time monitoring, data collection, and analysis. This connectivity enables plant managers to have a comprehensive view of asset health and operational efficiency, facilitating quicker decision-making. The data-driven insights offered by IIoT solutions aid in optimizing asset usage, identifying potential issues early, and ensuring that maintenance activities are performed efficiently. As industries continue to digitalize, IIoT-based plant asset management solutions are becoming essential tools for enhancing productivity, reducing operational costs, and improving overall asset reliability.

Stringent Regulatory Compliance and Safety Requirements:

Regulatory compliance and safety standards are increasingly influencing the adoption of plant asset management systems. In sectors, such as chemicals, pharmaceuticals, and energy, strict regulations mandate the regular inspection, maintenance, and reporting of equipment conditions. Non-compliance can result in heavy penalties, operational halts, or even accidents. Moreover, companies are investing in asset management solutions that not only ensure optimal functioning but also help in adhering to legal and safety requirements. These systems facilitate easier tracking of maintenance records, inspections, and compliance metrics, reducing the likelihood of regulatory breaches. Additionally, maintaining a safe working environment by preventing equipment failures also mitigates the risk of accidents, further driving the demand for reliable asset management solutions.

Plant Asset Management Market Report Segmentation:

Breakup By Offering:

Software

Services

Services exhibit a clear dominance in the market due to the growing demand for specialized maintenance, support, and consultation required for managing complex industrial assets.

Breakup By Deployment Mode:

Cloud-based

On-premises

Cloud-based represents the largest segment because of its scalability, cost-effectiveness, and ability to provide real-time data access and remote monitoring across multiple locations.

Breakup By Asset Type:

Production Asset

Motors, Rotating, Reciprocating Equipment

Process and Mechanical Equipment

Remote Equipment, Wiring and Other Electrical Equipment

Automation Assets

Field Devices

Control Values Position and Associated Equipment

Production asset (motors, rotating, reciprocating equipment, process and mechanical equipment, and remote equipment, wiring and other electrical equipment) hold the biggest market share, as it is critical to core operations, requiring continuous monitoring and maintenance to ensure high productivity and minimal downtime.

Breakup By End User:

Energy and Power

Oil and Gas

Petrochemical

Mining and Metal

Aerospace and Defense

Automotive

Others

Energy and power account for the majority of the market share owing to its heavy reliance on efficient asset management to maintain uninterrupted service and meet regulatory standards.

Breakup By Region:

North America (United States, Canada)

Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

Latin America (Brazil, Mexico, Others)

Middle East and Africa

North America enjoys the leading position attributed to its advanced industrial infrastructure, stringent regulations, and strong focus on sustainability and asset optimization.

Top Plant Asset Management Market Leaders:

The plant asset management market research report outlines a detailed analysis of the competitive landscape, offering in-depth profiles of major companies. Some of the key players in the market are:

ABB Ltd

Bentley Systems Incorporated

Emerson Electric Co.

Endress+Hauser AG

General Electric Company

Honeywell International Inc.

Rockwell Automation Inc.

Schneider Electric SE

Siemens AG

Yokogawa Electric Corporation

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

IMARC Group is a global management consulting firm that helps the world’s most ambitious changemakers to create a lasting impact. The company provide a comprehensive suite of market entry and expansion services. IMARC offerings include thorough market assessment, feasibility studies, company incorporation assistance, factory setup support, regulatory approvals and licensing navigation, branding, marketing and sales strategies, competitive landscape and benchmarking analyses, pricing and cost research, and procurement research.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: [email protected]

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.