Predictive Maintenance Market Release Latest Trends & Industry Vision by 2030

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

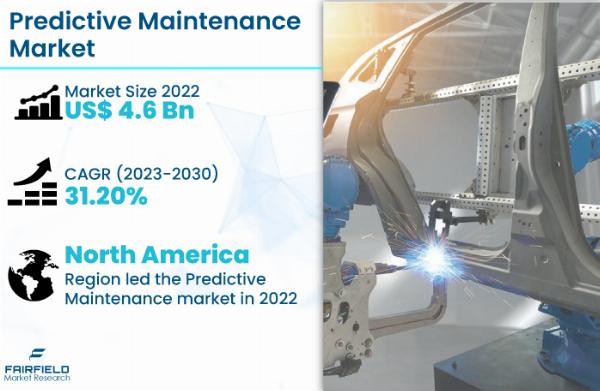

Fairfield Market Research, a leading market intelligence firm, has released its latest report on the Global predictive maintenance market, projecting a significant surge from its current value of approximately $4.6 billion to a staggering $30.8 billion by the year 2030. This exponential growth is expected to be driven by various factors, including increasing adoption in manufacturing applications, the demand for enhanced operational efficiency, and the necessity to reduce equipment downtime.

Key Trends Fueling Predictive Maintenance Market Growth

1. Manufacturing Applications Spearheading Growth: The report identifies a major trend in the rising popularity of predictive maintenance within manufacturing applications. As industries seek to optimize maintenance schedules, prevent equipment failures, and reduce downtime, the adoption of predictive maintenance technologies continues to soar across various sectors.

2. Dominance of On-Premises Deployment: On-premises deployment holds sway in the predictive maintenance market, particularly due to its data control capabilities crucial for sectors with strict compliance requirements. Additionally, its compatibility with existing infrastructure solidifies its dominance in the market.

3. Integrated Solutions Streamlining Operations: Integrated solutions are at the forefront of predictive maintenance, offering end-to-end functionality that simplifies implementation and decision-making processes. These solutions streamline maintenance processes, leading to enhanced operational efficiency and cost savings for organizations.

4. North America Leading the Charge: North America leads the predictive maintenance market, leveraging its well-established industrial sectors and technological advancements. A robust ecosystem of solution providers and stringent regulatory compliance further propels its growth trajectory.

5. Rapid Growth in Asia Pacific: The Asia Pacific region experiences the highest compound annual growth rate (CAGR) in the predictive maintenance market, fueled by rapid industrialization, particularly in countries like China and India. Initiatives such as Industry 4.0 and expansions in automotive and manufacturing sectors are key drivers of demand in this region.

Key Growth Determinants

• Emerging Technologies: The increasing use of technologies like IoT sensors, machine learning, and data analytics empowers organizations to collect and analyze vast amounts of data, leading to proactive maintenance strategies and substantial cost savings.

• Real-Time Condition Monitoring: Continuous monitoring of equipment health through real-time condition monitoring enables organizations to detect anomalies and potential failures, allowing for proactive maintenance actions and reduced downtime.

• Cost Reduction and Downtime Optimization: By shifting from traditional, time-based maintenance approaches to predictive maintenance strategies, organizations can achieve significant cost savings while maintaining operational efficiency and asset reliability.

Major Restraints

• Lack of Skilled Workforce: The shortage of skilled professionals in data analytics, machine learning, and IoT technologies poses a challenge to the successful implementation of predictive maintenance solutions, underscoring the need for investment in training and development programs.

• Data Ownership and Privacy Concerns: Balancing the need for data access with privacy concerns and regulatory requirements remains a challenge in the predictive maintenance market, emphasizing the importance of robust data governance and security measures.

Key Trends and Opportunities

1. IoT Sensors: IoT sensor technology plays a crucial role in predictive maintenance by continuously collecting and transmitting equipment data for real-time analysis, enabling proactive maintenance actions.

2. Edge Computing: Edge computing revolutionizes predictive maintenance by processing data closer to the data source, reducing latency and enabling real-time analysis for quicker response to anomalies.

3. Cloud Computing: Cloud computing offers scalable data storage and processing capabilities, facilitating access to predictive insights and informed maintenance decisions.

Regional Frontrunners

• North America: Home to well-established industrial sectors and a robust ecosystem of technology providers, North America leads the predictive maintenance market.

• Asia Pacific: Rapid industrialization and government initiatives promoting smart manufacturing drive significant growth in the Asia Pacific region.

Leaders in the Global Predictive Maintenance Market

1. IBM

2. SAP

3. Microsoft

4. General Electric

5. Schneider Electric

6. Siemens

7. Honeywell

8. PTC

9. ABB

10. Bosch

11. Rockwell Automation

12. C3.ai

13. Uptake

For More Insights into the Market Read Predictive Maintenance Market Press Release at:https://www.fairfieldmarketresearch.com/press-release/global-predictive-maintenance-market

For More Industry Insights Read:https://www.fairfieldmarketresearch.com/report/predictive-maintenance-market

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.