QFN Package Guide: Benefits, Structure, and Usage in PCB Assembly

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

As modern electronics evolve, so does the demand for high-performance, compact, and thermally reliable components. One of the most important innovations meeting this demand in PCB assembly services is the QFN package—short for Quad Flat No-Lead.

This compact packaging technology is revolutionizing the way devices are designed, enabling engineers to deliver smaller, faster, and more cost-effective electronics without compromising on thermal or electrical integrity.

📦 Types of QFN Packages

Different designs of QFN packages suit specific needs in terms of thermal performance, inspection, and I/O capacity:

✅ 1. Standard QFN (Single Row)

Features: Side-terminated contacts, large thermal pad

Ideal for: Compact electronics with tight board space

Use Cases: Power ICs, IoT modules, mobile devices

✅ 2. Dual Row QFN

Features: Two rows of contacts for higher pin count

Ideal for: Complex ICs needing more I/O lines

Use Cases: Advanced microcontrollers, comms ICs

✅ 3. Wettable Flank QFN

Features: Beveled edge plating for easy AOI inspection

Ideal for: High-reliability applications

Use Cases: Automotive ECUs, aerospace systems

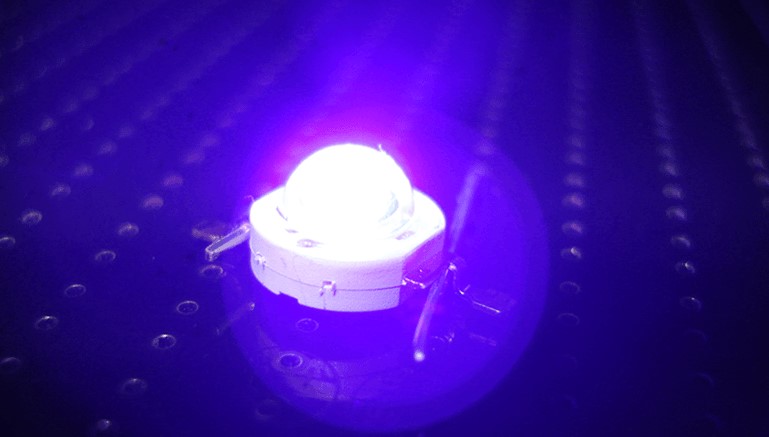

✅ 4. Air Cavity QFN

Features: Internal air gap reduces parasitic capacitance

Ideal for: RF and high-frequency analog designs

Use Cases: Radar systems, telecom modules, RF amplifiers

💡 Why Is the QFN Package Used in PCB Assembly?

QFN components are widely adopted in PCB assembly company in USA due to their superior size-to-performance ratio and cost efficiency. Key benefits include:

Compact Size – Perfect for smartphones, wearables, and IoT

Superior Thermal Dissipation – Thanks to the exposed pad

High Signal Integrity – Short paths reduce inductance

Cost Efficiency – Lower cost than BGA with comparable performance

These benefits make the QFN package ideal for PCB assembly companies focused on miniaturization and high reliability.

🛠️ How Are QFN Packages Made?

The QFN manufacturing process is engineered for scalability and precision. Here's a simplified breakdown:

1. Die Attachment

The silicon die is mounted on a copper lead frame with conductive adhesive. The pad becomes the heat transfer interface. This pad also acts as the heat dissipation interface once integrated into the PCB assembly process.

🔧 Foundation for thermal and mechanical integrity

2. Wire Bonding

Gold or aluminum wires connect the die to surrounding leads.

🔧 Enables data and power signal transmission

3. Encapsulation (Molding)

The package is sealed with epoxy resin for durability.

🔧 Protects the internal components from moisture and damage

4. Singulation

The packages are separated using sawing or punching.

🔧 Creates individual, surface-mountable QFN units

5. Surface Finishing

Leads are coated with finishes like NiPdAu, matte tin, or silver.

🔧 Ensures solderability and protects against oxidation

🔍 What Are the Components of a QFN Package?

A typical QFN package includes:

Exposed Thermal Pad – Directs heat to the PCB

Peripheral Pads – Located beneath the package

Wire Bonds – Connect internal die to outer pads

Mold Compound – Protects internal circuitry

Pin 1 Indicator – Assists with automated placement

These components ensure the package remains small, durable, and thermally reliable.

⚙️ Materials Used in QFN Packages

The following materials are selected for electrical performance and solderability:

Leadframe: Copper or alloy for heat dissipation

Bond Wires: Gold or aluminum for signal fidelity

Molding Compound: Epoxy resin for encapsulation

Solder Finish: NiPdAu, matte tin, or silver

Material uniformity ensures long-term performance and compliance with high-speed PCB assembly services.

🌐 Common Applications of QFN Packages

QFN packages are used across industries due to their performance and versatility:

Consumer Electronics: Smartphones, tablets, wearables

Automotive Systems: ECUs, ADAS, infotainment modules

Medical Devices: Diagnostic tools, hearing aids

Industrial Controls: PLCs, motor drivers, power modules

Telecom Infrastructure: RF processors, switches, amplifiers

Their durability and small footprint support the design of compact, rugged electronics.

Your choice depends on your project’s needs for size, thermal regulation, and inspection compatibility.

✅ Conclusion

The QFN package is more than a trend—it's a cornerstone of modern PCB assembly. Its blend of thermal efficiency, signal integrity, and miniaturization makes it ideal for advanced electronics across sectors.

By partnering with a seasoned PCB assembly company like A2Z Electronics LLC, you gain access to proven expertise in QFN packaging—from component sourcing to precision placement and reflow soldering. Get in touch today and future-proof your designs with trusted QFN solutions.

You May Also Read : PCB Assembly vs. PCB Fabrication: What to Choose for Your Next Electronics Project

❓ FAQs

Q1. What does QFN stand for?

QFN stands for Quad Flat No-Lead, a compact IC package with terminals located underneath the body, enhancing heat dissipation and board space optimization.

Q2. What is the full form of QFN package?

It’s Quad Flat No-Lead Package. "Quad" denotes four edges, "Flat" signals low profile, and "No-Lead" refers to the absence of external pins.

Q3. What’s the difference between DFN and QFN packages?

DFN has leads on two sides, while QFN features terminals on all four edges, offering more I/O and better thermal performance.

Q4. What’s the difference between LGA and QFN packages?

LGA uses flat pads for pressure contact, often socketed. QFN is soldered directly to the board, ideal for permanent, high-density installations.

Q5. What is the size of a standard QFN package?

Sizes vary from 3×3 mm to 12×12 mm, supporting various pin counts (e.g., 32-pin in 5×5 mm).

Q6. What is the structure of a QFN package?

A QFN consists of a die on a thermal pad, wire-bonded to a lead frame, and encapsulated in a mold compound, with pads exposed for surface mounting.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.