Revolutionizing Aerospace Coatings: Trends and Innovations

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction:

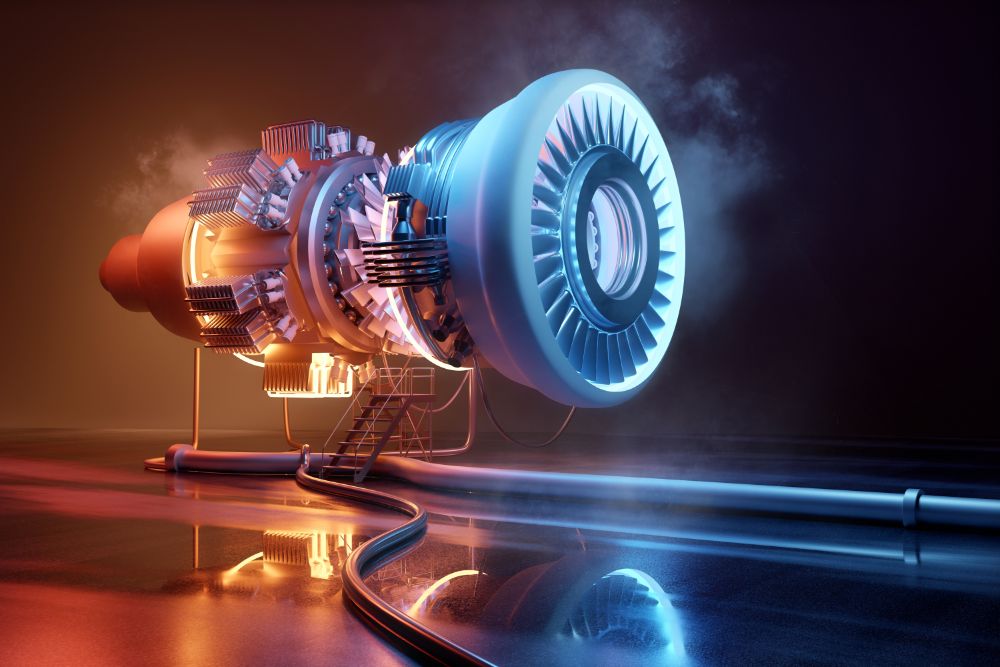

Aerospace coatings play a pivotal role in the performance, safety, and longevity of aircraft, spacecraft, and satellites. From the protective coatings on aircraft bodies to the specialized materials used in space exploration, coatings are integral to ensuring optimal operation in some of the most demanding environments. As technology advances, aerospace coatings are evolving with new innovations that enhance performance, sustainability, and efficiency. Among the most exciting developments are smart aerospace coatings, which leverage sensors and self-repairing technologies to further improve the reliability and functionality of aerospace systems.

This article explores recent trends and developments in aerospace coatings, with a focus on the cutting-edge advancements in smart coatings. We’ll look at how these coatings are changing the aerospace landscape, providing enhanced protection and more efficient, cost-effective solutions for the aerospace industry.

1. What Are Aerospace Coatings and Why Are They Essential?

Aerospace coatings are specialized materials applied to the surfaces of aircraft, spacecraft, and satellites. These coatings serve several important functions, including:

Protection from Environmental Damage: Aircraft and spacecraft are exposed to harsh environmental conditions, such as extreme temperatures, humidity, saltwater, and UV radiation. Coatings act as protective barriers, preventing corrosion and reducing wear and tear.

Fuel Efficiency and Aerodynamics: Coatings can help reduce drag by providing a smooth surface, improving the overall aerodynamic efficiency of aircraft. This translates to better fuel economy and reduced environmental impact.

Thermal and Radiation Protection: In space, spacecraft and satellites must deal with temperature extremes and radiation. Specialized coatings provide insulation and protect sensitive components from these hazards.

Surface Aesthetics: Coatings not only improve the performance and durability of aerospace vehicles but also contribute to their visual appeal, helping manufacturers and airlines maintain brand identity and improve customer perception.

In recent years, the focus has shifted toward advanced coatings that do more than just protect the surface. Smart coatings, incorporating sensors and self-repairing technologies, represent a significant leap forward in aerospace coating innovation.

2. What Are Smart Aerospace Coatings?

Smart coatings are a new generation of coatings that integrate advanced technologies to provide enhanced functionality beyond traditional protection. These coatings can sense changes in their environment, monitor the health of the surface, and even repair themselves when damaged. The two most notable advancements in smart aerospace coatings are:

Sensors Integrated into Coatings: Smart coatings equipped with sensors can detect various factors such as pressure, temperature, humidity, and impact. These sensors can monitor the condition of the coating in real-time, providing valuable data that helps maintain the health of aircraft and spacecraft.

Self-Repairing Technologies: Self-healing coatings can repair minor damage, such as scratches or cracks, autonomously. This ability helps extend the life of the coating and reduce maintenance costs, as minor damages are automatically addressed without the need for manual intervention.

Let’s take a closer look at how these two innovations are transforming the aerospace industry.

3. How Do Sensors in Aerospace Coatings Enhance Performance and Safety?

The integration of sensors into aerospace coatings offers numerous benefits for both the operational performance and safety of aircraft and spacecraft. These sensors can monitor the condition of the coating and provide early warnings of potential issues, helping to prevent costly repairs or failures.

A. Detecting Structural Damage and Wear

One of the most significant advantages of sensors embedded in coatings is their ability to detect early signs of damage or wear on the surface. Sensors can measure changes in pressure, temperature, and strain that indicate the presence of cracks, stress, or material degradation. For example:

Crack Detection: Sensors embedded in the coating can detect when cracks begin to form on the surface of the aircraft or spacecraft. This information can trigger an alert, prompting maintenance teams to address the issue before it worsens.

Corrosion Monitoring: Corrosion is one of the most common causes of aircraft and spacecraft failure. Sensors can track moisture levels, temperature fluctuations, and environmental conditions to detect the early stages of corrosion, allowing for timely intervention.

B. Monitoring Environmental Conditions

Smart coatings can also monitor environmental factors that may affect the performance of aerospace vehicles. This includes temperature, humidity, UV radiation, and atmospheric pressure. For example:

Temperature Sensors: Coatings with temperature sensors can detect areas of excessive heat, which is particularly useful for spacecraft reentering the Earth’s atmosphere. These sensors can provide real-time data on heat levels and help optimize the vehicle’s thermal protection system.

UV and Radiation Monitoring: Spacecraft and satellites operating in outer space are subjected to intense radiation from the sun and cosmic rays. Smart coatings with built-in radiation sensors can detect harmful radiation levels and provide insights into how well the coating is protecting the vehicle from radiation damage.

C. Enabling Predictive Maintenance

By collecting data on the condition of the coating and the environment, smart coatings allow for predictive maintenance. This approach moves away from traditional scheduled maintenance and instead focuses on addressing issues as soon as they arise. Predictive maintenance helps reduce downtime, increase operational efficiency, and lower the overall cost of repairs.

4. How Do Self-Repairing Technologies in Aerospace Coatings Work?

Self-repairing coatings represent a major leap in the development of aerospace coatings. These coatings are designed to automatically fix minor damage, such as scratches, cracks, and chips, without human intervention. The technology behind self-repairing coatings is based on a variety of mechanisms, including:

Microencapsulation: In this approach, tiny capsules containing a healing agent are embedded in the coating. When the coating is damaged, the capsules break open, releasing the healing agent that fills in the cracks or scratches and bonds the surface back together.

Vascular Systems: Similar to the circulatory system in living organisms, vascular systems are networks of channels embedded within the coating. When damage occurs, the channels release healing agents to repair the surface.

Shape Memory Polymers (SMPs): These materials can return to their original shape when exposed to certain conditions, such as heat. SMPs are incorporated into coatings to allow them to ‘heal’ by reshaping themselves and closing minor cracks or deformations.

Self-repairing coatings are particularly valuable in aerospace applications, as they reduce the need for frequent touch-ups or maintenance and extend the lifespan of the vehicle. For example:

Aircraft: Self-repairing coatings can address small scratches or surface cracks that could otherwise lead to corrosion or other performance issues. This means fewer disruptions to flight schedules and less downtime for maintenance.

Spacecraft and Satellites: In the extreme environment of space, even small amounts of damage can have serious consequences. Self-repairing coatings help ensure that spacecraft and satellites can continue to operate efficiently, even after sustaining minor damage.

5. What Are the Benefits of Smart Aerospace Coatings?

The integration of sensors and self-repairing technologies into aerospace coatings offers a range of advantages for the aerospace industry, including:

Increased Safety: Sensors that detect early signs of damage or wear help prevent accidents and failures, ensuring the safety of both passengers and crew.

Cost Savings: By enabling predictive maintenance and reducing the need for frequent repairs, smart coatings help reduce operational costs. Self-repairing coatings also minimize the need for manual intervention, lowering labor costs.

Extended Lifespan: The ability to detect and repair damage in real-time allows aerospace vehicles to operate for longer periods without the need for costly refurbishments or replacements.

Enhanced Efficiency: Smart coatings optimize the performance of aerospace vehicles by reducing drag, preventing corrosion, and ensuring that components remain in peak condition for longer.

6. What Does the Future Hold for Smart Aerospace Coatings?

The future of the Smart Aerospace Coatings Market looks promising, with continued research and development leading to more advanced materials and technologies. Some potential future developments include:

Download FREE Sample of Aerospace Coatings Market

Advanced Self-Healing Materials: Future self-healing coatings will likely be more efficient, capable of repairing a wider range of damages and functioning in more extreme environments.

Integration with AI and Machine Learning: Smart coatings could integrate with artificial intelligence (AI) and machine learning systems to predict maintenance needs and optimize performance, further enhancing operational efficiency.

Sustainability: As the aerospace industry strives for more sustainable practices, smart coatings will likely evolve to be more eco-friendly, utilizing renewable materials and reducing environmental impact.

Conclusion

Smart aerospace coatings, which incorporate sensors and self-repairing technologies, are transforming the aerospace industry. These coatings offer a wide range of benefits, from improving safety and performance to reducing costs and enhancing operational efficiency. As technology continues to advance, the potential for even more sophisticated coatings will reshape the way aircraft, spacecraft, and satellites are maintained and operated, ensuring a safer, more sustainable future for aerospace exploration. Whether for commercial aviation or space missions, smart coatings are set to play a pivotal role in the skies and beyond.

Read the complete blog

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.