Website Copy Makeover – Turn Visitors into Buyers Instantly!

Website Copy Makeover – Turn Visitors into Buyers Instantly!

Roles and Responsibilities of a Tannic Acid Manufacturer in Delhi

Written by Aryan Chemicals » Updated on: June 17th, 2025

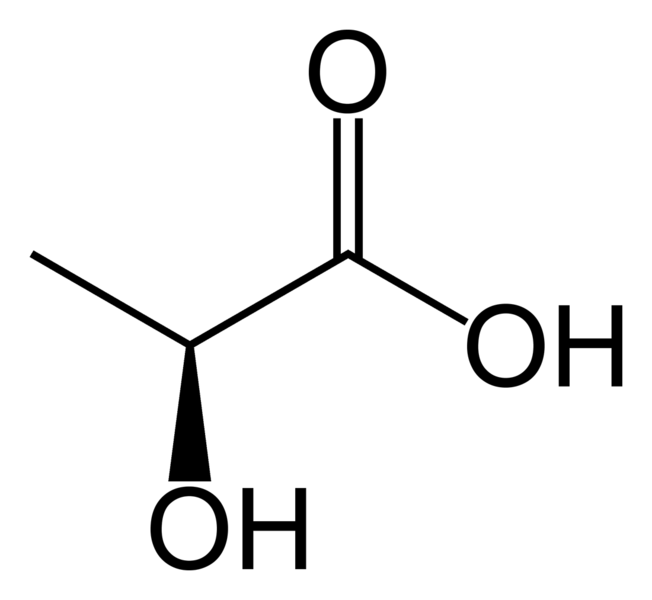

Tannic acid, a polyphenolic compound derived from plants, is widely used across various industries like pharmaceuticals, food and beverages, textiles, and more. Manufacturers of tannic acid play a crucial role in ensuring that the production and supply of this versatile compound meet high standards of quality and safety. In a bustling industrial hub like Delhi, tannic acid manufacturers must adhere to strict regulations, market demands, and the dynamic nature of various industries that use the product. The roles and responsibilities of a tannic acid manufacturer in Delhi are multifaceted and vital for ensuring smooth operations and customer satisfaction.

1. Production and Manufacturing

The primary responsibility of a tannic acid manufacturer is the production of high-quality tannic acid. This process involves sourcing raw materials like oak wood, tea leaves, or gallnuts, which are rich in tannins. These raw materials undergo an extraction process, where tannins are separated and refined to produce tannic acid.

Manufacturers need to ensure that the production process is efficient and follows industry-standard procedures. This includes:

Selecting Raw Materials: Choosing the right quality of plant-based sources.

Extraction Process: Implementing methods like solvent extraction or precipitation to isolate tannic acid.

Purification: Ensuring the tannic acid is free from contaminants and impurities.

Consistency in Production: Maintaining the quality and quantity of the product batch after batch.

2. Quality Control and Compliance

Manufacturers must adhere to strict quality control measures. In an industry where quality is paramount, tannic acid manufacturers need to have robust systems in place for testing and inspecting the final product. This ensures that the tannic acid is pure, potent, and safe for use.

Quality control responsibilities include:

Raw Material Inspection: Testing raw materials before the extraction process to confirm their suitability.

In-Process Testing: Monitoring the production stages to check for any anomalies that may affect the quality.

Final Product Testing: Conducting rigorous testing of the final product to ensure it meets industry standards and regulatory requirements.

Compliance with Regulatory Standards: Manufacturers must comply with national and international regulations, such as the Food Safety and Standards Authority of India (FSSAI) for food-grade tannic acid, or pharmaceutical-grade standards for medicinal use.

3. Research and Development (R&D)

To stay competitive in the market and meet evolving industry needs, tannic acid manufacturers often invest in research and development. R&D activities focus on improving the extraction process, developing new uses for tannic acid, and enhancing its efficiency.

The R&D team’s roles include:

Product Innovation: Exploring new uses for tannic acid in various sectors, such as biodegradable materials, medicine, and cosmetics.

Improving Extraction Techniques: Finding ways to improve yield and reduce costs during the extraction process.

Sustainability: Developing eco-friendly processes and reducing the environmental footprint of production.

4. Supply Chain Management and Logistics

Supply chain management is a key responsibility for tannic acid manufacturers. Ensuring a steady supply of raw materials, managing production schedules, and maintaining a smooth distribution system are critical for meeting market demand. Tannic acid is used in various sectors, which require timely deliveries to avoid production delays.

Key supply chain roles include:

Raw Material Sourcing: Establishing reliable relationships with suppliers of raw materials, ensuring their quality, and maintaining a consistent supply.

Inventory Management: Managing inventory levels to avoid shortages or overstocking.

Distribution and Delivery: Ensuring that the finished product reaches customers in a timely manner, often dealing with both domestic and international shipments.

5. Customer Relationship Management

Customer satisfaction is central to the success of any business, and tannic acid manufacturers are no exception. Maintaining strong relationships with existing clients while attracting new customers is crucial. The responsibilities here include:

Understanding Client Needs: Engaging with customers to understand their specific needs, such as the concentration or grade of tannic acid they require.

Customization: Providing customized solutions to clients based on their industry-specific requirements.

After-Sales Support: Offering technical support and addressing any issues or queries that customers might have after the product is delivered.

6. Health and Safety Standards

Manufacturers in Delhi must prioritize the health and safety of their employees. Manufacturing tannic acid involves handling chemicals and substances that can be hazardous if not managed properly. Ensuring that all safety protocols are followed is essential to prevent accidents, injuries, and damage to health.

Safety responsibilities include:

Workplace Safety: Ensuring proper protective gear and safety measures for all employees involved in the production process.

Employee Training: Regular training sessions on safe handling practices and emergency protocols.

Maintaining Cleanliness: Ensuring that production facilities are clean and free from contaminants to prevent cross-contamination of products.

7. Marketing and Sales

To stay competitive in the market, tannic acid manufacturers must also engage in strategic marketing and sales. This includes identifying potential markets, promoting their product offerings, and participating in industry trade shows and exhibitions.

Key roles in marketing and sales include:

Market Research: Understanding trends in industries that use tannic acid, such as food, pharmaceuticals, and textiles.

Sales Strategy: Developing a sales strategy that includes pricing, promotion, and customer outreach.

Brand Development: Building a reputable brand that reflects the quality and consistency of the product.

Conclusion

Tannic acid manufacturers in Delhi play a vital role in producing a valuable product used across various industries. Their responsibilities range from production and quality control to research and development, supply chain management, and customer relations. In a fast-paced and competitive market, manufacturers must focus on efficiency, innovation, and adherence to safety and quality standards to maintain their position and contribute to the success of industries that depend on tannic acid.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.