Room Heater Testing As Per IS 302-2-30 (2007) Standard

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

A room heater is an electrical or gas-powered appliance that people use to heat indoor spaces during cold weather. This device is designed to offer heating in homes, offices, or small areas. In particular, it is one of the most important solutions for comfort and warmth in winter. Room heater testing as per IS 302-2-30 (2007) standard is an essential evaluation technique to ensure that your heater gives out the right amount of heat and does not overheat while operating. If you want to know what exactly a room heater testing as per IS 302-2-30 (2007) standard is, let's talk about what it entails in simple terms:

Introduction to Room Heater Testing as per IS 302-2-30 (2007) Standard

Room heater testing as per IS 302-2-30 (2007) standard mainly focuses on checking the safety and performance of electric room heaters in India. Manufacturers rely on this testing method to produce reliable and trustworthy room heaters, including fan heaters, oil-filled heaters, and quartz heaters.

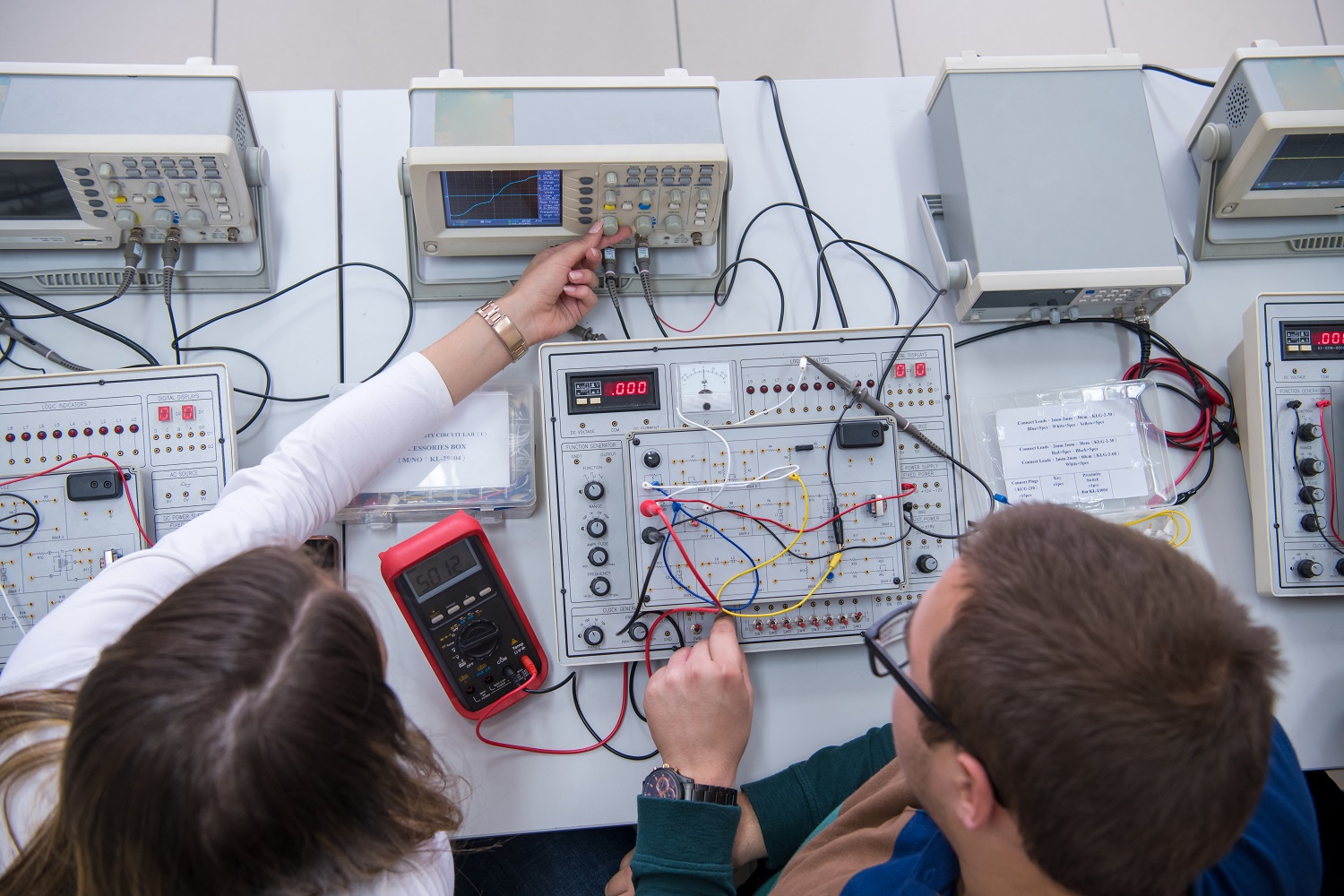

A trained team of experts offers room heater testing services. They carry out the tests using the IS 302-2-30 (2007) standard and use tools like temperature testers, insulation testers, and high-voltage testers to check the room heater’s safety and performance. With the help of room heater testing as per IS 302-2-30 (2007) standard, you can ensure that the heater you have manufactured is safe to use, energy efficient, and meets Indian safety standards.

Types of Room Heater Testing?

Room heater testing covers various types of tests to check different aspects of the heater. From temperature rise tests to leakage current tests, each type helps users to ensure the safety, efficiency, and durability of their products under various conditions. Let’s talk about the types of room heater testing:

Temperature Rise Test

The temperature rise test is the most important way to check how hot the heater part gets during use. This evaluation method helps to identify problems and malfunctions of your room heater. With the help of this electronics testing, you can prevent burns or fire hazards. The temperature rise test gives you confidence to sell your products effectively in the market.

Insulation Resistance Test

The insulation resistance test helps manufacturers measure the insulation of the electrical parts of the heater. This ensures that there is no risk of electric shock, short circuit or fire. Insulation resistance testing is an important part of home appliance testing designed for home appliances such as room heaters. It enhances wiring safety, improves reliability, and provides performance during everyday use.

High Voltage Test

High-voltage tests ensure room heaters can handle voltage surges without failing. A manufacturer who wants to prevent electrical malfunctions may resort to high-voltage testing to enhance product safety. You can also comply with safety standards and regulations. This evaluation method avoids electrical shocks, improves safety, and prevents damage during the use of the product.

Earth Continuity Test

The earth continuity test ensures that the heater is properly grounded. This test method protects users from electrical shock, improves safety, and confirms that the electrical path is complete for safe fault current flow. This examination process helps heater makers ensure their product is safe and won’t cause electric shocks to customers.

Power Consumption Test

The power consumption test is an ideal test method to check the energy efficiency potential of a room heater. This home appliance test checks how much electricity the heater uses during its operation. Manufacturers get to know that their product is working perfectly and will not increase their consumer bills much.

Leakage Current Test

The leakage current test is a part of environmental testing that checks if any harmful electrical current is leaking from the heater. This helps users to use it safely. A trained team of experts helps users check if any harmful electrical current is leaking from the heater. This ensures safety by preventing electric shock and maintaining trust and meeting safety standards.

Mechanical Strength Test

Mechanical strength testing ensures that the room heater is strong and durable. This increases its longevity and enables it to withstand wear and tear. Mechanical testing prevents damage during handling or use, reducing the risk of injury, malfunction, or product failure.

Bottom Line

Room heater testing as per IS 302-2-30 (2007) allows manufacturers to ensure proper markings of their room heaters. It analyses its voltage, maintenance, installation, and other aspects of the heater. Testing your home appliance against these standards ensures clear user instructions for safe operation, maintenance, and installation. That helps users operate the heater correctly and reduce the risk of misuse or accidents.

Small and large manufacturers of room heaters turn to a recognised testing laboratory for comprehensive testing solutions. Today, the testing services' support allows businesses to test their products and make their room heaters ideal for the preferences of the audience. Room heater testing services help them to make their products in line with local and global standards and avoid legal consequences.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.