Scraped Surface Heat Exchangers Market: A Solution for Challenging Processes

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The Scraped Surface Heat Exchangers (SSHEs) Market addresses these challenges by offering a unique and specialized heat transfer technology that excels in such demanding environments. This article delves into the Scraped Surface Heat Exchangers market, exploring its evolution, applications, key players and future growth trends.

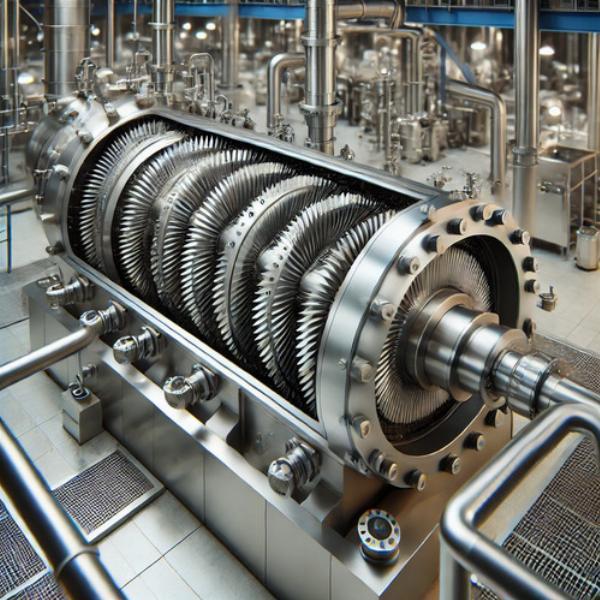

Introduction to Scraped Surface Heat Exchangers

Scraped Surface Heat Exchangers (SSHEs) are heat transfer devices specifically designed for heating, cooling, or crystallizing viscous, sticky, or heat-sensitive materials. The internal design features rotating blades or scrapers that continuously remove product buildup from the heat transfer surface. This action ensures consistent heat transfer rates, minimizes fouling, and improves product quality, making SSHEs indispensable in various industries, including food processing, pharmaceuticals, cosmetics and chemicals.

Evolution of the Scraped Surface Heat Exchangers Market

The SSHE market has witnessed significant growth over the years as industries increasingly demand efficient solutions for handling complex and challenging processes. Initially developed for the dairy industry, where products like creams and yogurts require careful thermal control, SSHEs have now expanded their use across diverse sectors. This evolution has been driven by advancements in SSHE design, materials and automation, enhancing their performance in different industrial applications.

Key Applications of Scraped Surface Heat Exchangers

The versatility of Scraped Surface Heat Exchangers makes them ideal for numerous industries:

Food and Beverage: SSHEs are widely used in the food industry for processing products such as sauces, soups, jams, and dairy items. These systems handle high-viscosity products while maintaining flavor, texture, and nutritional value.

Pharmaceuticals: In the pharmaceutical industry, SSHEs are used for producing ointments, gels, and creams, where precise thermal control is essential to ensure product stability and quality.

Chemical Processing: In the chemical industry, SSHEs help manage high-viscosity products like resins, polymers, and adhesives. Their ability to maintain heat transfer efficiency in demanding conditions is key to consistent product output.

Cosmetics: The cosmetics industry relies on SSHEs to process creams, lotions, and other skincare products, ensuring smooth textures and high product quality.

Benefits of Scraped Surface Heat Exchangers

High Efficiency: SSHEs are engineered to provide efficient heat transfer, especially for high-viscosity materials that would otherwise cause fouling in traditional heat exchangers.

Improved Product Quality: Continuous scraping of the surface prevents buildup and overheating, preserving the integrity of heat-sensitive products.

Versatility: SSHEs are flexible and can handle a wide range of products with different viscosities, making them essential for various industries.

Easy Cleaning and Maintenance: The design of SSHEs allows for easy cleaning, which is critical in industries like food and pharmaceuticals where hygiene is a top priority.

Leading Manufacturers in the Scraped Surface Heat Exchangers Market

Several key players dominate the Scraped Surface Heat Exchangers market, providing innovative solutions to meet industrial needs. These companies focus on product customization, improved efficiency, and customer support. Some of the leading manufacturers include:

SPX FLOW Inc.

Alfa Laval AB

Kelvion Holding GmbH

HRS Heat Exchangers

APV Systems

These companies are continuously innovating their products, incorporating automation, real-time monitoring, and sustainable designs to stay competitive in the market.

Market Segmentation by Type and Application

The SSHE market can be segmented by type and application:

By Type: Batch SSHEs, Continuous SSHEs, and Hybrid SSHEs.

By Application: Food & Beverage, Pharmaceuticals, Chemicals, and Cosmetics.

Each type of SSHE offers unique advantages, with batch systems favored for small-scale production and continuous systems preferred for high-volume processes.

Future Growth Prospects and Trends

The Scraped Surface Heat Exchangers market is expected to grow significantly in the coming years, driven by the increasing demand for efficient heat transfer systems in complex industrial processes. Key trends shaping the market include:

Sustainability: Companies are increasingly focusing on energy-efficient SSHE designs to reduce operational costs and environmental impact.

Automation: Advanced control systems and real-time monitoring of SSHEs are becoming more common, enabling industries to optimize their processes with minimal human intervention.

Customization: With industries having unique processing requirements, manufacturers are offering customized SSHE solutions to meet specific needs.

Conclusion

The Scraped Surface Heat Exchangers market continues to expand as industries seek more efficient and reliable solutions for managing complex, heat-sensitive and viscous products. With advancements in design, automation and sustainability, SSHEs are positioned to play a critical role in the future of heat transfer technology across multiple sectors. As the demand for high-quality, energy-efficient and versatile heat exchangers grows, SSHEs are set to remain at the forefront of challenging industrial processes.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.