Smart Tips to Save Space with Industrial Storage Racks in Your Warehouse

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Running out of warehouse space? The issue might not be your square footage—it’s how you’re using it. With the right planning and proper racking systems, even compact warehouses can operate smoothly and efficiently. In this blog, Sigma Racks shares practical tips to help you optimize your existing space without costly expansion.

Sigma Racks has worked in warehouses of all sizes and has observed firsthand how Industrial Storage Racks can transform cluttered layouts into well-structured, highly efficient operations. In the event that your warehouse is starting to feel overcrowded, here are some practical suggestions to ensure that you make the most of your space, while maintaining safety and speed.

1. Go Vertical with the Right Racking

The quickest way to save space is to look up. Many warehouses underuse their vertical height. Installing Heavy-Duty Pallet Racking Systems or longspan shelving lets you store more without increasing your building footprint. These racks are designed to handle weight safely while improving access to stock.

2. Use the Right Rack for the Right Product

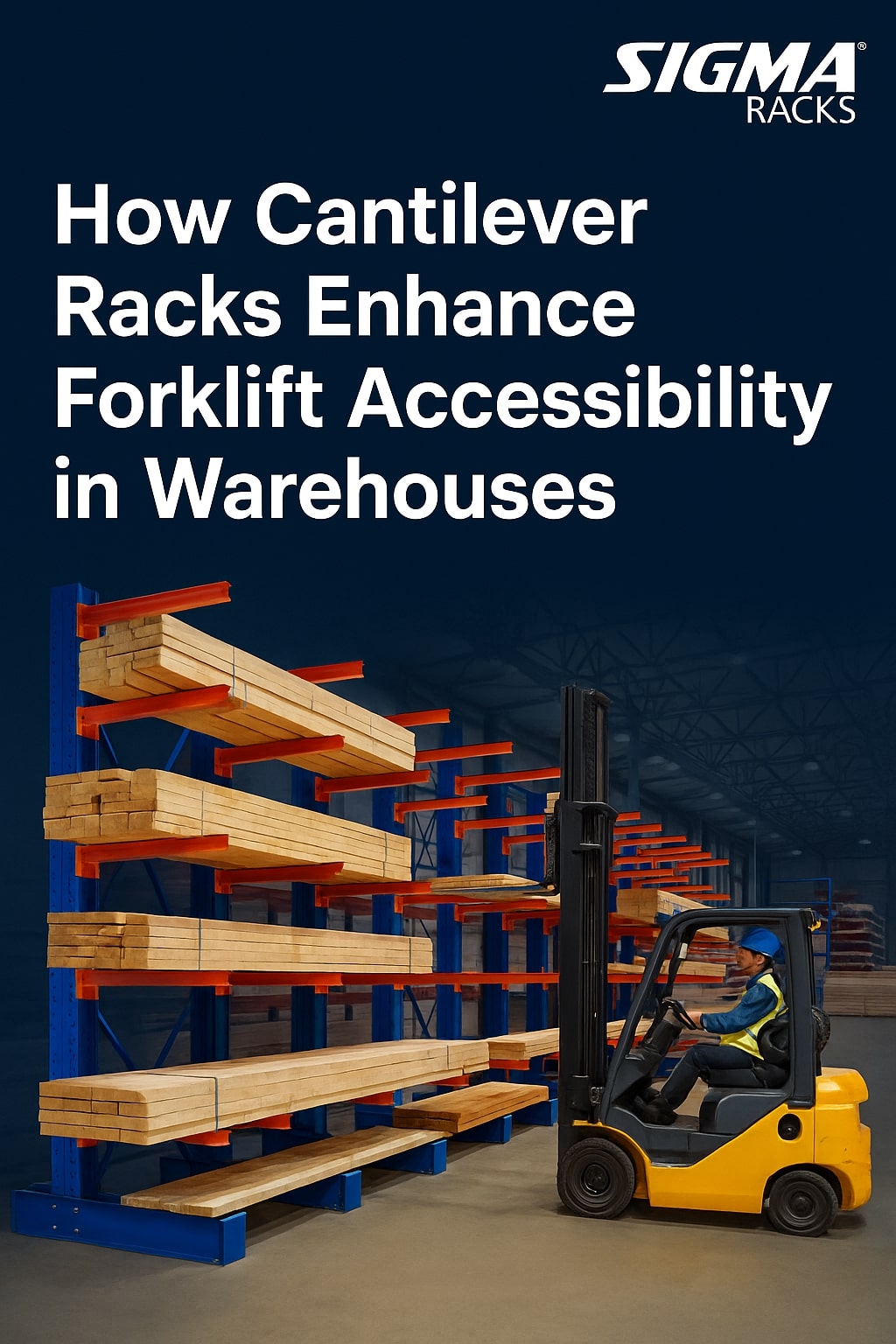

Trying to fit every item into one kind of rack is a common mistake. Long items like pipes and rods? Use Cantilever Racking Systems. Small parts and tools? Pigeon hole racking or slotted angle racks are ideal. When products are matched with suitable storage, it reduces wasted space and improves picking speed.

3. Optimize Aisle Widths and Layout Flow

There should not be a lot of empty space between racks, as this will reduce your total storage area. On the other hand, too little space will cause movement to be slowed and create safety hazards. Plan your layout according to the type of equipment you will be using (manual or forklift), and ensure aisle widths are optimized - not just random.

4. Add a Mezzanine Floor

Creating a Mezzanine Floor System is a cost-effective way to double the usable space of an existing facility without major construction. You can utilize the upper level for storage, offices, or packing zones. It is like adding a second floor without constructing a new building.

5. Keep Fast-Moving Stock Close

The most commonly picked items should be located near packing or dispatch zones if your warehouse layout is rearranged. By doing so, you will reduce unnecessary walking and free up more space in high-traffic areas. A good warehouse racking system is not just for storing — it is also for making moving within the warehouse easier.

Why Industry Leaders Prefer Sigma Racks?

Sigma Racks is a leading provider of customized storage systems designed around your space, your products, and your working pace. Our racks are produced using automated machinery for precision, durability, and consistent quality. We also offer factory-direct pricing and pan-India shipping, ensuring you receive both value and performance.

From modular shelving to custom-built mezzanine floors, we help businesses rethink their storage — not just expand it.

📞 Need help optimizing your warehouse layout? Call: +91-9670777737

🌐 Visit: www.sigmastorage.com

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.