The Complete Beginner’s Guide to Mastering Resin 3D Printing

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

If you’ve ever scrolled through photos of incredibly detailed miniatures, dental models, or sleek product prototypes, you’ve probably already seen the magic of resin 3D printing at work. While filament-based 3D printers get plenty of attention, resin printers are quietly revolutionizing industries that demand precision, smooth surfaces, and intricate detail.

For hobbyists, professionals, or complete newcomers looking to explore the world of high-resolution 3D creation, this guide will walk you through what resin 3D printing is, why it’s different, and how you can get started successfully.

What Is Resin 3D Printing?

Resin 3D printing is a type of additive manufacturing that uses liquid photopolymer resin as the raw material, which is cured layer by layer using light—typically UV light—to build objects. The two most common methods are SLA (Stereolithography) and DLP (Digital Light Processing), both of which offer incredible accuracy and detail.

Unlike FDM (Fused Deposition Modeling), which extrudes melted plastic, resin printing creates parts by solidifying a liquid resin into a solid layer. This makes it ideal for small, highly detailed parts where surface finish and dimensional accuracy are critical.

Why Choose Resin Over FDM?

Before you decide on your first 3D printer, it’s important to understand the pros and cons of different technologies. Here’s why many people are turning to resin:

1. Superior Detail and Surface Finish

Resin printers can achieve layer heights as low as 25 microns, resulting in incredibly smooth finishes and highly detailed prints. This is why they’re often used for figurines, jewelry, dental applications, and even engineering prototypes.

2. Complex Geometry Made Easy

Because of the way light cures resin, complex geometries with overhangs, fine details, and intricate inner structures are much easier to print cleanly compared to filament printers.

3. Material Versatility

Today’s resin market offers a wide range of options—standard, flexible, tough, high-temperature, dental, and even castable resins for metal casting. This allows users to choose exactly the right material for their project needs.

4. Less Warping and Layer Lines

FDM prints often suffer from warping or obvious layer lines. Resin prints tend to avoid these issues, giving users a more professional result with minimal post-processing.

The Resin Printing Workflow (And What You’ll Need)

While resin 3D printing is powerful, it’s a bit more involved than plug-and-play filament printing. Here’s a quick overview of the workflow and what’s required:

Step 1: Choose a Resin Printer

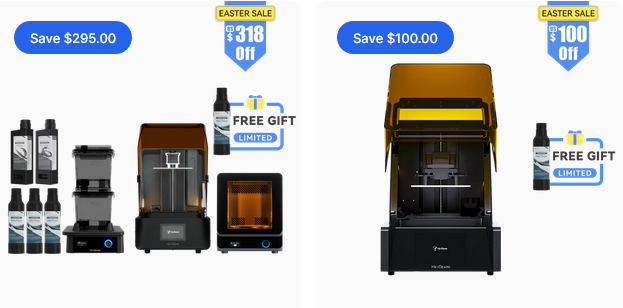

Modern desktop resin printers come in many forms, with varying build sizes, resolutions, and light technologies (LCD, SLA, or DLP). Brands like HeyGears, Anycubic, and Elegoo offer solid options for both beginners and professionals.

When selecting your machine, consider:

Build volume: How large do you need your prints to be?

Resolution: Higher resolution means finer details.

Ease of maintenance: How easy is it to clean and replace parts?

Slicing software: Is it intuitive and compatible with common file types?

Step 2: Pick the Right Resin

Not all resins are created equal. Some are brittle but detailed; others are tough but sacrifice precision. Match your material to your application. For instance:

Standard resin for general-purpose prints.

Tough or ABS-like resin for functional parts.

Flexible resin for rubber-like components.

Biocompatible or dental resin for medical applications.

Step 3: Slice Your Model

You’ll need slicing software to convert your 3D model into printer instructions. Popular slicers like Chitubox, Lychee Slicer, or proprietary tools from printer manufacturers allow you to:

Orient and scale your model

Add supports (critical for overhangs)

Adjust exposure times and layer heights

A good slice is the difference between a perfect print and a failed one, so don’t rush this step.

Step 4: Printing and Monitoring

Once sliced, you transfer your file to the printer (usually via USB or Wi-Fi), pour your resin into the vat, and start printing. Print times vary by object height and layer thickness. Be patient—resin printing isn’t fast, but the results are worth it.

Keep an eye on the print early in the process to catch any errors like failure to adhere to the build plate.

Step 5: Post-Processing

This is where resin printing differs most from FDM. After printing, your part isn’t ready until it’s washed and cured.

Washing: Remove uncured resin using isopropyl alcohol (IPA). This can be done manually or with a wash station.

Curing: Use a UV curing chamber or sunlight to finish hardening the part. Improper curing can affect strength and finish.

Support removal: Carefully cut away supports using flush cutters or tweezers.

Finishing touches: Sanding or priming might be necessary depending on your final use.

Common Beginner Mistakes (And How to Avoid Them)

If you’re new to resin 3D printing, mistakes are part of the learning curve. Here are a few common pitfalls and how to dodge them:

Insufficient support structures: Leads to failed or sagging prints.

Inadequate curing: Results in soft or sticky surfaces.

Dirty FEP film or vat: Affects print quality and adhesion.

Overexposure or underexposure: Can cause prints to warp, over-cure, or delaminate.

Always follow your resin and printer manufacturer’s exposure settings as a baseline and adjust as needed.

Is Resin 3D Printing Right for You?

Ask yourself what you value most in a 3D printer:

Need high-detail prints for display or prototyping? Resin is for you.

Want functional parts with excellent surface quality? Resin still wins.

Looking for a quick and easy hobby with minimal cleanup? You might prefer FDM.

That said, even with its post-processing demands, many users fall in love with the incredible output of resin machines. Once you print your first detailed miniature or dental arch, it’s hard to go back.

Tips for Getting the Best Results

Here are a few tips to keep your resin printing experience smooth and productive:

Work in a ventilated area and wear gloves when handling resin.

Store resin properly in opaque, sealed containers to avoid degradation.

Clean your equipment regularly—resin can gunk up quickly.

Level your build plate frequently to ensure consistent adhesion.

Use exposure calibration tools to dial in perfect settings for each resin type.

Final Thoughts

Resin 3D printing opens up a world of possibilities for creators, engineers, medical professionals, and hobbyists alike. With its unmatched detail and material versatility, it’s quickly becoming the go-to solution for anyone who wants professional-grade parts at home.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.