The Essential Guide to Heat Exchangers: Types and Applications

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

They form an integral part of a variety of industrial procedures. They facilitate the transfer of energy across various fluids. This guide explains the basic principles of heat exchangers, their many types in addition to their diverse uses. This guide will explain the function of Nash vacuum pumps in enhancing certain heat exchange systems.

What are Heat Exchangers?

Heat exchangers are made to make it easier for the transfer of heat between the two liquids or. The fluids could be directly in contact, or separated using an impermeable barrier that stops mixing. The main function of heat exchangers is can be to rise efficiency of energy by transferring heat from warmer fluids into a cooler, which conserves the energy and reduces costs.

The Importance of Heat Exchangers

Within the field of energy production as in chemical processing, as well as HVAC (heating and ventilation and cooling) heat exchangers can be essential role. They boost the effectiveness of energy production, regulate temperature fluctuations in processes, and improve efficiency of the entire system. These payoff can be significant in terms of beneficial economic and environmental benefits.

Types of Heat Exchangers

There is a wide range kinds of heat exchangers which were designed to fit the needs of a specific customer. There are various varieties of heat exchangers such as:

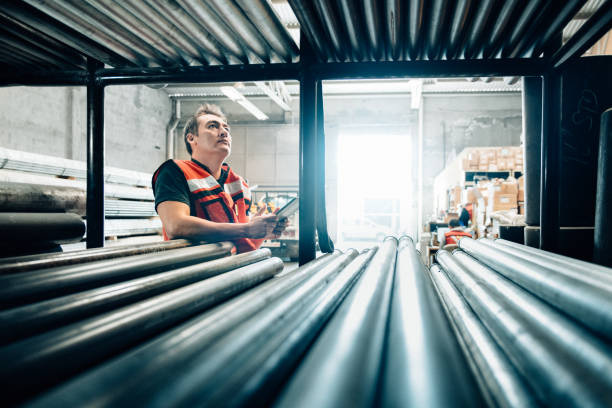

1. Shell and Tube Heat Exchangers

Tube heat exchangers and shells could be one of the more popular types. They comprise several tubes. There is one tube that carries hot fluid and the other carrying cold liquid. They are wrapped in an oval shell, which permits heating to be transferred between two fluids. The type is frequently employed in refineries, power stations along with chemical facilities because of its flexibility as well as its efficiency.

2. Plate Heat Exchangers

Heat exchangers for plates consist of many small Corrugated plates stackable. Each plate has a channel that allows fluids moving through the channels in alternating fashion. The huge area of the plates enhances the effectiveness of the heat transfer. Plates with heat exchangers typically are used in food production or refrigeration and the water processing.

3. Air-Cooled Heat Exchangers

The air-cooled exchangers,, often known as finned tube heat exchangers make use of cooling air to reduce the temperature of the liquid. They comprise tubes that have fins joined to rise the surface area that allows heat dissipation. They are usually used in locations that do not have water accessible or when additional cooling is needed, such as for power stations, Petrochemical plant.

4. Double Pipe Heat Exchangers

Double pipe heat exchangers are the most basic form, consisting of two pipes which are in a concentric arrangement. One fluid is pumped through the inner pipe while the other moves through the annular space that is between the pipe. This kind pipe is ideal for small-sized applications in terms of size and require the smallest of footprints, as well as cost-effective costs are important.

5. Spiral Heat Exchangers

Spiral heat exchangers consist of two channels, which spiral. There have one channel per liquid. They create an unidirectional flow which yields efficiently efficient thermal transfer. They're ideal for handling viscous fluids in addition to liquids making them suitable for businesses that need paper or pulp in addition to the treatment of water.

Applications of Heat Exchangers

They are employed across numerous applications.

- Power generation is an essential part of steam generation and condenser cooling. Recycling of heat from waste.

- Chemical Processing Assures that the process operates with the correct temperature within the distillation columns as well as other chemical processes.

- HVAC Systems Transmits heat out of cooling and heating systems to regulate the temperature of indoors.

- Food and Beverage Industry This ensures the safe sanitation, sterilization, and storage of food products in all forms.

- Oil and Gas Industry The process used to refine the gas compression process, Liquifaction and liquefaction.

The Role of Nash Vacuum Pumps in Heat Exchange Systems

Nash vacuum pumps are often employed for heat exchange for the purpose of increase efficiency. They create the illusion of a vacuum, by decreasing the temperature of liquid, as well as increasing the transmission of energy. It allows the processes like condensing, evaporation, or distillation to occur at lower temperatures and pressures thus reducing energy use and operating expenses.

Conclusion

They're essential elements of various industrial processes. They provide efficiency in heat transfer and conserving energy. Learning about the various types of heat exchangers as well as their applications can aid in deciding on the best one that meets your needs. Furthermore, the use of technologies like Nash vacuum pumps can improve the efficiency of heat exchangers. This leads to greater efficiency as well as reductions. With the development of technologies in industries and technology, the use of heat exchangers are essential to the development of environmentally friendly and productive processes.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.