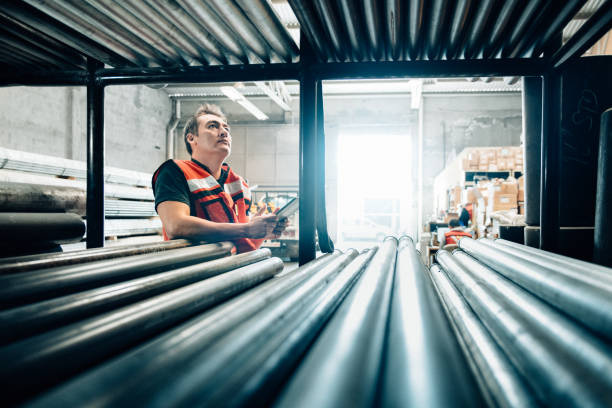

Understanding Industrial Metal Supply: A Vital Component of Modern Infrastructure

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The position of commercial metallic supply in shaping nowadays’s infrastructure is simple. From skyscrapers to bridges and pipelines to machinery, metals serve as the spine of commercial progress. This significant and interconnected device ensures that industries starting from construction and automotive to energy and manufacturing have constant get right of entry to to the substances they want. Without a dependable industrial metal supply, the chain of development can be extensively hindered.

Modern business operations rely closely at the efficient sourcing, processing, and distribution of various metals. This includes carbon metal, chrome steel, aluminum, copper, and more. Alongside these, the steel and pipe supply area supports industries by way of supplying critical components used in structural and mechanical programs. Together, they shape an atmosphere that fuels country wide and international economies.

Types of Metals in Industrial Supply Chains

Structural Steel

Structural steel remains one of the most extensively used materials in creation. Its high power, flexibility, and affordability make it perfect for frameworks of homes, bridges, and business facilities. It comes in various shapes and grades tailor-made to unique applications, together with beams, angles, and channels.

Stainless Steel

Stainless metallic is vital in environments in which corrosion resistance is important. Found in food processing flora, medical gadgets, and chemical factories, it is valued for its sturdiness, hygienic residences, and aesthetic appeal.

Aluminum and Non-Ferrous Metals

Aluminum is every other major participant in industrial metallic deliver because of its lightweight and splendid resistance to corrosion. It is usually utilized in transportation, aerospace, and packaging industries. Non-ferrous metals like copper, brass, and bronze also are necessary in electric, plumbing, and architectural packages.

The Supply Chain Behind Industrial Metals

Raw Material Extraction and Processing

The journey begins with the extraction of raw ore from mines. This raw cloth is then processed into usable metallic via smelting and refining. The complexity of this manner depends on the metallic being produced and its supposed use.

Distribution Networks

Once processed, the metals are allotted through a large network of suppliers and distributors. This step is essential because it bridges the distance among manufacturers and give up customers. Efficient logistics and stock management make certain timely deliveries and limit downtime for industries that rely on just-in-time production models.

Fabrication and Customization

Metals frequently require cutting, bending, welding, and different fabrication strategies earlier than being suitable for very last use. Industrial metallic supply providers generally provide those offerings to fulfill the precise needs of their customers, improving performance and reducing overall mission costs.

Industrial Applications and Uses

Construction Industry

Construction remains the largest patron of commercial metals. Steel beams, rebar, pipes, and sheets shape the inspiration of residential, industrial, and infrastructural tasks. Metal’s strength and durability make certain the toughness and protection of those structures.

Oil and Gas Sector

The oil and gas enterprise heavily is predicated at the metallic and pipe supply chain to supply excessive-grade metal pipes capable of withstanding extreme pressures and temperatures. These pipes are vital in both offshore and onshore drilling operations and the transportation of oil and natural fuel.

Manufacturing and Heavy Equipment

Manufacturing industries use a big selection of metals in creating machinery, tools, and components. These encompass elements for motors, generators, engines, and industrial machines. Reliability and electricity are key attributes that make metals a desired preference in those packages.

Challenges in the Metal Supply Industry

Fluctuating Prices

Metal fees are difficulty to international market forces, which includes supply and call for, geopolitical factors, and production fees. These fluctuations can make budgeting hard for industries counting on consistent costs.

Environmental Concerns

Mining and metallic processing have environmental implications which include emissions, water utilization, and waste technology. There is increasing pressure on businesses inside the business metallic supply chain to adopt sustainable practices and reduce their carbon footprint.

Supply Chain Disruptions

Natural screw ups, political instability, and pandemics can disrupt the supply chain, leading to shortages and delays. Diversification of sourcing and improved transparency are techniques industries use to mitigate these dangers.

Innovations Shaping the Future of Metal Supply

Automation and Digitalization

Modern metallic supply chains are an increasing number of adopting virtual gear to enhance accuracy, pace, and efficiency. Automated warehouses, predictive analytics, and digital stock structures enable providers to control resources better and respond to market needs hastily.

Sustainable Practices

Recycling is gaining traction as an environmentally accountable manner to meet steel needs. Recycled metallic and aluminum require drastically less electricity than producing new metal, reducing the enterprise's average environmental impact.

Advanced Materials and Alloys

Technological advancements have led to the improvement of high-performance alloys that provide advanced strength, warmness resistance, and corrosion protection. These substances are particularly valuable in industries like aerospace, protection, and energy, wherein overall performance and reliability are important.

Regional and Global Outlook

Domestic Production vs. Import Dependence

Countries with wealthy mineral resources and robust manufacturing abilties consciousness on self-sufficiency in business metal supply. However, many countries also rely on imports to fulfill their wishes, making worldwide exchange and logistics key components of the metallic supply panorama.

Economic Growth and Infrastructure Development

The demand for commercial metals often mirrors financial activity. Developing nations experiencing rapid industrialization generally show improved intake of metallic, aluminum, and other key metals. Infrastructure initiatives, along with highways, bridges, and ports, function predominant drivers of metal demand in those regions.

Choosing the Right Supplier

Reliability and Quality

Consistency in first-rate and well timed shipping are crucial trends of a reliable steel provider. Industrial initiatives perform on tight schedules, and any delays can have cascading results on productivity and price.

Product Range and Services

An perfect dealer offers a extensive variety of merchandise, from uncooked sheets and beams to fabricated custom components. Additional services like cutting, coating, and transportation can add price to the overall supply package deal.

Compliance and Certification

Suppliers need to adhere to enterprise standards and rules. Certifications related to safety, environmental compliance, and first-class assurance make certain that the substances meet the required specifications and are secure to apply in essential applications.

Conclusion

The commercial metallic delivery machine is a long way more than a simple transaction of goods. It is a complicated and strategic component of contemporary improvement, helping limitless industries and driving innovation. From sourcing uncooked materials to turning in precision-reduce steel elements, this deliver chain keeps the wheels of progress turning.

The synergy between industrial metallic carriers and the steel and pipe supply network enables the construction of resilient infrastructure, the operation of heavy machinery, and the innovation of destiny technology. As industries grow and evolve, so too will the steel deliver systems that assist them—becoming smarter, extra sustainable, and more and more essential to global development.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.