The Future of Manufacturing: Harnessing Innovation for Sustainable

Strong8k brings an ultra-HD IPTV experience to your living room and your pocket.

As the world undergoes rapid technological advancement, the manufacturing industry stands at the forefront of innovation. From automation and robotics to sustainable practices and digitalization, this article explores the transformative trends shaping the future of injection molding gates and driving sustainable growth.

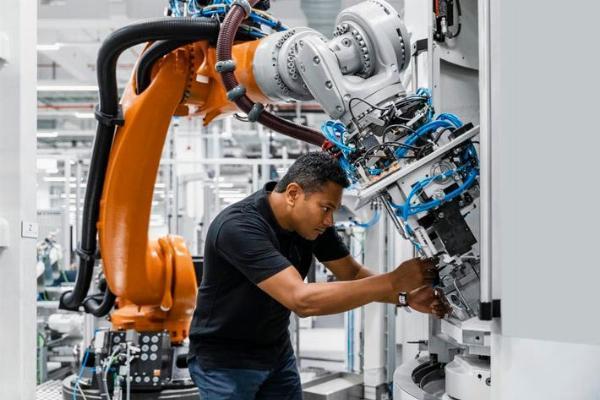

Advanced Robotics and Automation:

Robots and automation have become integral to modern manufacturing, revolutionizing production processes and enhancing efficiency. Advanced robotics, equipped with artificial intelligence and machine learning capabilities, can perform intricate tasks with speed and precision. Collaborative robots, or cobots, work alongside human operators, increasing productivity and safety on the factory floor. Automation streamlines workflows, reduces lead times, and minimizes errors, driving competitiveness and growth in the manufacturing sector.

Additive Manufacturing (3D Printing):

Additive manufacturing, also known as 3D printing, is reshaping traditional manufacturing methods, offering unparalleled design freedom and customization. By building objects layer by layer from digital models, 3D printing enables rapid prototyping, on-demand production, and complex geometries that were previously impossible to achieve. This technology is revolutionizing industries such as aerospace, automotive, and healthcare, where customization and innovation are paramount. Additive manufacturing minimizes waste, reduces costs, and accelerates time-to-market, driving sustainable growth and innovation in manufacturing.

Sustainable Practices and Circular Economy:

Sustainability has become a core focus for manufacturers as they seek to minimize environmental impact and meet consumer demand for eco-friendly products. Sustainable manufacturing practices include using renewable energy sources, minimizing waste, and implementing circular economy principles. Companies are adopting closed-loop systems, where products are designed for reuse, recycling, and remanufacturing, reducing resource consumption and waste generation. Sustainable practices enhance brand reputation, attract environmentally conscious consumers, and drive long-term profitability in the manufacturing industry.

Digital Transformation and Industry 4.0:

Digital transformation is reshaping the manufacturing landscape, ushering in the era of Industry 4.0. This paradigm shift is characterized by the integration of cyber-physical systems, the Internet of Things (IoT), and data analytics into manufacturing processes. Smart factories leverage real-time data and connectivity to optimize production, improve quality control, and enable predictive maintenance. Digital twins, virtual representations of physical assets and processes, enable simulation, analysis, and optimization, driving efficiency and innovation in manufacturing operations.

Supply Chain Resilience and Agility:

The COVID-19 pandemic has underscored the importance of supply chain resilience and agility in manufacturing. Companies are reevaluating their mim parts meaning, diversifying suppliers, and leveraging digital technologies to enhance visibility and flexibility. Blockchain technology ensures transparency and traceability across the supply chain, reducing the risk of disruptions and enabling faster response to changing market conditions. Supply chain optimization drives efficiency, reduces costs, and enhances resilience, ensuring sustainable growth and competitiveness in the manufacturing industry.

Conclusion:

The future of manufacturing is characterized by innovation, sustainability, and digitalization. By harnessing advanced technologies such as robotics, additive manufacturing, and digital transformation, manufacturers can drive sustainable growth, improve efficiency, and meet the challenges of a rapidly evolving market. Embracing sustainable practices, fostering supply chain resilience, and adapting to changing consumer preferences will be key to achieving long-term success and competitiveness in the manufacturing industry

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.