The Role of FPC Connectors in Modern Mobile Phone Technology

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Introduction

The development of mobile phones from simple devices for communication to advanced multifunctional gadgets has been absolutely groundbreaking. Their sleek design and a powerful performance is an extremely complex system of electronic parts. In this regard, Flexible Printed Circuits (FPCs) are now a fundamental element of design for mobile devices. They allow smaller profiles, better quality, and increased adaptability in design.

One of the most important elements that facilitates the connecting of these circuits that are flexible various internal components is the fpc connector mobile phone interface. The tiny, but powerful component ensures an uninterrupted communication between the device's circuitry as well as functional components including the display, camera as well as the battery.

What is an FPC Connector?

A FPC connector can be described as a form of connector for electrical use that's made to connect various flexible printed circuits to circuit boards or parts of electronic devices. They are utilized for a wide range of small devices like phones, tablets, smartwatches and various other wearables with internal space at an all-time low and flexibility is essential.

FPC connectors can be found in different shapes and sizes, which include zero insertion Force (ZIF) and low Instability Force (LIF) kinds. They typically employ an encapsulation or latching mechanism to hold the FPC to the wall, ensuring the electrical connection and ensuring the mechanical stability.

Benefits of Using FPCs and FPC Connectors in Mobile Phones

Space Efficiency

Modern smartphones are built to be small and light and yet contain increasingly sophisticated parts. FPCs with the ability to bend and fold, let engineers make the most of spaces more effectively. If they are paired with connectors that are compact They ensure the best use of space inside the device.

Weight Reduction

Flexible circuits and connectors are considerably lighter than conventional wiring systems and rigid PCBs. This is a major reason for the light smartphone, which improves the user's comfort as well as portability.

Enhanced Durability

FPCs and connectors can be much more robust than conventional connectors. The components that are used in these circuits were made to stand up to repeated stress and the harsh conditions of environmental. When combined with high-quality connectors and connectors, they provide better longevity as well as less maintenance.

Design Flexibility

FPC connectors offer the most flexibility in layout design. Engineers can design more intricate designs and more ergonomic design without having to worry about strict PCB restrictions. This has resulted in developments like folding phones, curving screens and components that are modular.

Key Applications of FPC Connectors in Mobile Devices

Display Integration

Modern mobile displays--particularly OLED and AMOLED screens--require precise and compact connectors to transmit data from the processor to the screen. FPC connectors are vital for these purposes, allowing speedy data transfer with little use of space.

Camera Modules

Camera modules are among the most advanced technological components of smartphones. FPC connectors aid in bridging the connection between the cameras as well as the processor in the main, making it possible to perform fast and precise image processing.

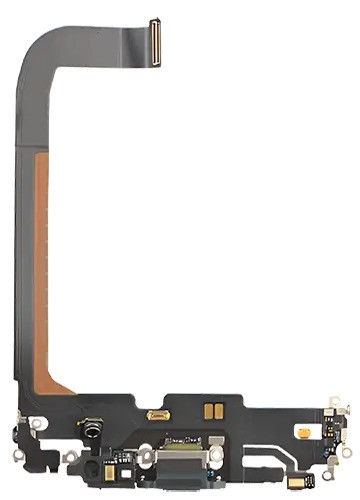

Battery and Charging Circuits

A smooth transfer of energy between the battery and other components of a mobile phone is essential. FPCs, in conjunction with sturdy connectors, provide low power losses as well as efficient current flow which allows for fast charging and extended battery life.

Antenna and Signal Transmission

With mobile phones continuing to incorporate features such as 5G as well as NFC keeping the integrity of signals is crucial. FPC connectors can be found in antennas to ensure the clarity of signals and fit into small antennas.

Challenges in FPC Connector Integration

Miniaturization

As the devices shrink and smaller, their parts must also shrink. Making FPC connectors with the ability to maintain functionality and are smaller in terms of size is always a issue. Manufacturers have to balance quality of the connector, its durability as well as ease of use in the process of designing.

Assembly Precision

Due to their tiny dimensions, FPC connectors require extremely exact alignment when they are assembled. Small errors could cause connection problems, which can affect the performance of the connector. Automatic placement, high-precision devices and even precision devices are often used to tackle this problem.

Thermal Management

Mobile devices are able to generate significant thermal heat, particularly when performing intense activities. Making sure that FPC connectors are able to function with different temperatures is crucial for reliability. Highly-performing materials and the right placement inside the device can help alleviate the effects of these problems.

Advances in FPC Connector Technology

High-Speed Data Transfer

As demand grows for recording 4K videos games, gaming with high resolution, as well as seamless multitasking FPC connectors have to now be able to handle higher speeds for data transmission. Modern designs incorporate shielding and upgraded contact materials in order to reduce delay and loss of signal.

Multi-Lane Interfaces

Connectors for FPC are currently being designed with multi-lane connectors which permit different signals to be passed through one connector. This allows for greater data storage but leaves a minimal footprint that is ideal for environments that are mobile.

Enhanced Locking Mechanisms

The latest connectors offer safe locking mechanisms that reduce the chance of disconnecting because of drops, shocks or the constant movement of devices. This is particularly important for devices where durability and reliability are essential.

Environmental and Sustainability Considerations

Since sustainability is becoming a global issue, companies are now focused on environmentally friendly materials and manufacturing processes. Soldering without lead, recycled materials as well as energy efficient manufacturing have become standard practice within the FPC and connector industry.

In addition there are companies that are investigating biodegradable connectors and substrates in order for reducing the amount of electronic waste. Although these technologies are at an early stage but they have promise in the near future for green electronics.

The Growing Market for FPCs and Connectors

Demand for FPCs as well as connectors for mobile devices is continuing to grow. According to research from the industry The world FPC market will grow significantly in the coming decade due to the rapid growth of mobile phones, IoT devices, and electronic wearables.

When companies continue to push the boundaries of smartphone design and performance it is imperative that high-end FPC connectors is becoming more essential. There are a growing range of design options that range from folding phones to modular devices, reliable interconnect products are not only helpful, but they are essential.

Understanding the Main FPC in Mobile Design

In every smartphone it is the fpc connector mobile phone serves as a central hub for interconnecting important components like the memory, CPU display and communications modules. The integration of sophisticated connectors will ensure the highest performance and efficiency. The main circuit, which is flexible, has to be extremely robust and reliable, since it serves as the foundation of the whole internal design.

The proper design and construction of the primary FPC and the connectors that it is connected to, will greatly impact the performance of devices as well as durability and satisfaction. With the advancement of features included in smartphones - such as fingerprint sensors and AI processors as well as foldable displays -- the significance and complexity of the primary FPC are only going to increase.

Conclusion

Flexible printed circuits and connectors for them aren't only components, they're the catalysts for innovation in the field of mobile phones. They can be used to improve design flexibility and improving the performance of phones, FPC connectors are indispensable for today's slim and high-end devices.

As demand for higher speeds, thinner profiles and greater performance, the value of improved FPC connectors is undisputed. Top manufacturers such as those that are featured on Gekunflex can be found on the forefront of this innovation shaping how mobile electronic devices will evolve using their expertise and the latest technologies.

While smartphones and mobile devices remain in development One thing is for certain that the simple FPC connector will continue to be vital in connecting technology and innovation.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.