The Role of Technology in Modern Backpack Manufacturing in the USA

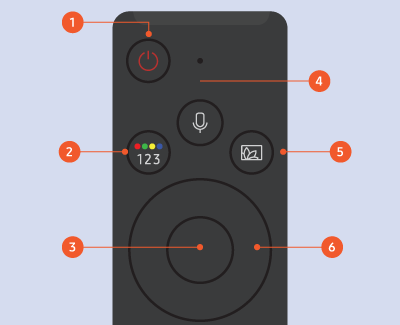

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

The U.S. backpack manufacturing industry has evolved significantly in recent years, thanks to the rapid advancements in technology. From automation to smart textiles, these innovations are not only improving the production process but also enhancing the quality and functionality of backpacks. As a result, many consumers are now able to enjoy durable, eco-friendly, and high-performance backpacks made right here in the United States. In this article, we’ll explore how these technological developments are shaping the future of backpack manufacturing in the USA.

Automation: Streamlining the Production Process

One of the most notable technological shifts in backpack manufacturing is the introduction of automation. In the past, backpacks were primarily assembled by hand, which was both time-consuming and prone to human error. Today, many leading Backpack Manufacturers in the USA have turned to automation to improve production efficiency and reduce costs.

Automated systems allow for faster and more precise cutting, stitching, and assembly of backpacks. For instance, robotic arms can now precisely stitch seams and attach zippers with minimal human intervention. This not only speeds up the production process but also ensures higher consistency in the final product. As a result, manufacturers can meet high-demand cycles while maintaining quality standards.

Additionally, automation helps USA backpack manufacturers reduce labor costs and improve overall scalability. By investing in automated equipment, these companies can produce larger quantities of backpacks in less time, making it easier to fulfill large orders for retailers and consumers alike. This has become especially important as e-commerce continues to rise, leading to an increase in demand for backpacks and related products.

3D Printing: Customization and Prototyping

Another groundbreaking technology that is transforming the way backpacks are designed and manufactured is 3D printing. In the past, creating prototypes for new backpack designs was a costly and time-consuming process. Today, backpack manufacturers are using 3D printing to quickly create prototypes, test new ideas, and even produce custom components for backpacks.

With 3D printing, manufacturers can experiment with different materials, designs, and features without committing to expensive production runs. For example, a company may print different variations of a backpack's zipper or strap design to determine which works best before beginning mass production. This allows for greater flexibility and experimentation during the product development stage, leading to more innovative and functional backpack designs.

Moreover, 3D printing also facilitates customization options for consumers. Some manufacturers now offer personalized backpacks with 3D-printed components, such as custom logos, initials, or designs. This level of personalization appeals to a growing market segment that values unique, one-of-a-kind products.

Smart Textiles: Enhancing Functionality and Durability

In addition to automation and 3D printing, smart textiles are becoming an integral part of modern backpack manufacturing in the USA. Smart fabrics are materials that are enhanced with technology to offer additional functionalities, such as water resistance, temperature regulation, and even solar power.

One of the most popular smart textile applications in backpacks is the integration of solar panels. Several backpack manufacturers in USA now produce backpacks with built-in solar panels that can charge devices on the go. This feature is particularly appealing to travelers, hikers, and outdoor enthusiasts who rely on their devices while in remote locations.

Other smart textiles are designed to enhance comfort and performance. For example, moisture-wicking fabrics can keep the contents of a backpack dry, even in humid conditions. Advanced fabrics with heat-insulating properties can help regulate the internal temperature of a backpack, ensuring that items like electronics or food remain at optimal temperatures.

Additionally, some manufacturers are experimenting with Choose the Right Fabric for Clothing Brand. These materials have the ability to repair small tears or punctures automatically, extending the life of the backpack and reducing the need for repairs or replacements.

Sustainability and Eco-friendly Materials

As technology continues to advance, backpacks in the USA are also focusing on sustainable practices. The demand for eco-friendly products has surged, and consumers are increasingly looking for backpacks made from recycled or biodegradable materials. Technological advancements in materials science have made it possible to produce high-quality, durable fabrics from recycled plastic bottles, organic cotton, and other sustainable resources.

For example, companies like Patagonia and North Face are incorporating recycled polyester and eco-friendly nylon into their backpacks, reducing the environmental impact of production. Additionally, advancements in textile recycling technologies are allowing manufacturers to recycle used backpacks and repurpose them into new products.

Not only do these sustainable materials help reduce waste, but they also contribute to a more positive brand image. Consumers today are more conscious of the environmental footprint of the products they purchase, and companies that embrace sustainable practices are often viewed more favorably.

The Future of Backpack Manufacturing in the USA

Looking ahead, the future of backpack manufacturing in the USA is set to be defined by even more technological innovations. As automation, smart textiles, and sustainable practices continue to evolve, we can expect to see even more advanced backpacks that are lighter, more durable, and packed with cutting-edge features.

Furthermore, the integration of artificial intelligence (AI) and machine learning could allow for even more personalized designs, predictive analytics for production demand, and smarter inventory management. With these advancements, backpack manufacturers in USA will continue to lead the charge in creating high-performance, innovative backpacks that meet the ever-changing needs of consumers.

Conclusion

In conclusion, technology is playing a pivotal role in shaping the future of backpack manufacturing in the USA. From automation and 3D printing to smart textiles and eco-friendly materials, these advancements are transforming the industry in exciting ways. As consumers continue to demand more functional, customizable, and sustainable products, backpack manufacturers in the USA will be at the forefront of delivering these innovations, driving the industry toward an exciting and sustainable future.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.