The Role of Technology in Today’s Plastics Molding Companies

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

In an era where precision, speed, and sustainability define manufacturing success, technology plays a transformative role in the plastics industry. For any modern injection molding company, embracing technological advancements is no longer optional—it’s essential. From design and prototyping to full-scale production and quality assurance, technology is reshaping how plastic parts are made, tested, and delivered. Particularly for a plastics molding company in California, staying ahead in tech adoption is crucial in meeting the state’s competitive and environmentally conscious manufacturing landscape.

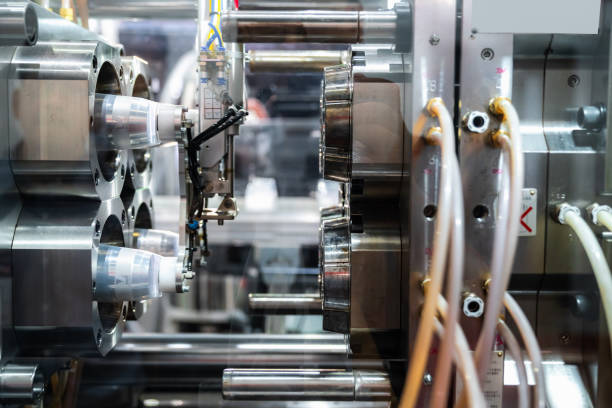

Smart Machines and Automation

The heart of today’s plastic molding operations lies in high-performance, computer-controlled machines. Automation in injection molding has become a game-changer, enabling companies to produce large volumes of plastic parts with unmatched speed and consistency. Modern injection molding machines are equipped with real-time monitoring, AI-driven process optimization, and predictive maintenance features. These technologies minimize downtime, reduce human error, and increase overall efficiency.

Automated robotic arms are commonly used for tasks such as part removal, trimming, labeling, or even assembly. This level of automation allows a plastics molding company in California to maintain high standards of safety while keeping labor costs in check. More importantly, it supports round-the-clock production, a key requirement for industries needing rapid delivery cycles.

Computer-Aided Design and Simulation

Before a single part is molded, design and simulation tools play a critical role in ensuring success. With advanced CAD (Computer-Aided Design) and CAE (Computer-Aided Engineering) software, engineers can design complex parts and molds with pinpoint accuracy. Mold flow simulation software helps predict how melted plastic will behave inside the mold, allowing designers to spot potential issues such as air pockets, warping, or weak points before production begins.

This digital approach minimizes costly trial-and-error during mold development. For an injection molding company, it not only shortens lead times but also helps deliver higher-quality parts with fewer defects—an essential factor in maintaining client trust and satisfaction.

Real-Time Monitoring and Quality Control

In today’s competitive landscape, quality is non-negotiable. Modern molding facilities now rely on IoT (Internet of Things) and data analytics tools to monitor every stage of the molding process. Parameters like temperature, pressure, cycle time, and material feed are tracked in real-time to ensure consistency.

This data-driven approach enables immediate response to any deviation from set standards. Smart sensors alert operators to possible problems before they affect product quality, leading to fewer rejected parts and reduced material waste. For a plastics molding company in California, where environmental regulations are strict, these technologies contribute to both quality assurance and sustainable manufacturing practices.

Advanced Materials and Precision Molding

Technology has also led to significant improvements in the materials used by today’s injection molding companies. Engineering-grade plastics, biodegradable resins, and specialty compounds are now readily available and tailored to meet the needs of industries like automotive, aerospace, medical, and electronics.

Using advanced materials also requires equally sophisticated molding equipment capable of handling varying temperatures, flow rates, and shrinkage behaviors. The best molding companies invest in multi-shot molding, overmolding, and micro-molding capabilities to meet the growing demand for complex and high-performance plastic components.

Integration of AI and Machine Learning

Artificial intelligence is beginning to make its mark on plastics manufacturing. AI algorithms can analyze historical production data to optimize parameters, predict maintenance needs, and enhance product quality. Machine learning models can also assist in scheduling production, minimizing energy use, and forecasting demand.

For an injection molding company, AI brings a competitive edge by enabling smarter decision-making and reducing overhead. In high-volume operations, even minor efficiency gains can translate into significant cost savings over time.

Digital Supply Chain and Client Collaboration

Technology doesn’t just improve production—it enhances communication and service. Cloud-based platforms now allow real-time updates and data sharing between the molding company and its clients. Customers can track order status, review part specifications, and approve designs digitally, which greatly accelerates the development cycle.

A plastics molding company in California can serve a national or global client base effectively by offering a digital-first approach to project management. These platforms improve transparency and build stronger relationships with clients, something that’s increasingly valued in today’s collaborative work environments.

Sustainability through Innovation

One of the biggest areas where technology makes an impact is sustainability. Modern molding equipment uses less energy, while waste reduction systems recycle excess plastic. Smart mold designs reduce material usage, and biodegradable or recycled resins help reduce environmental impact.

California’s stringent environmental policies encourage manufacturers to go green, and technology is a key enabler. Companies that integrate energy-efficient machines, closed-loop systems, and sustainable materials gain a significant edge in both compliance and reputation.

Conclusion

The role of technology in today’s plastics molding industry is profound and continues to grow. For any injection molding company or plastics molding company in California, leveraging technology isn’t just about staying competitive—it’s about leading the way. From automation and AI to sustainability and digital collaboration, technology empowers these companies to meet the evolving needs of modern manufacturing while delivering precision, efficiency, and reliability.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.