The Ultimate Guide to Siemens CAM

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

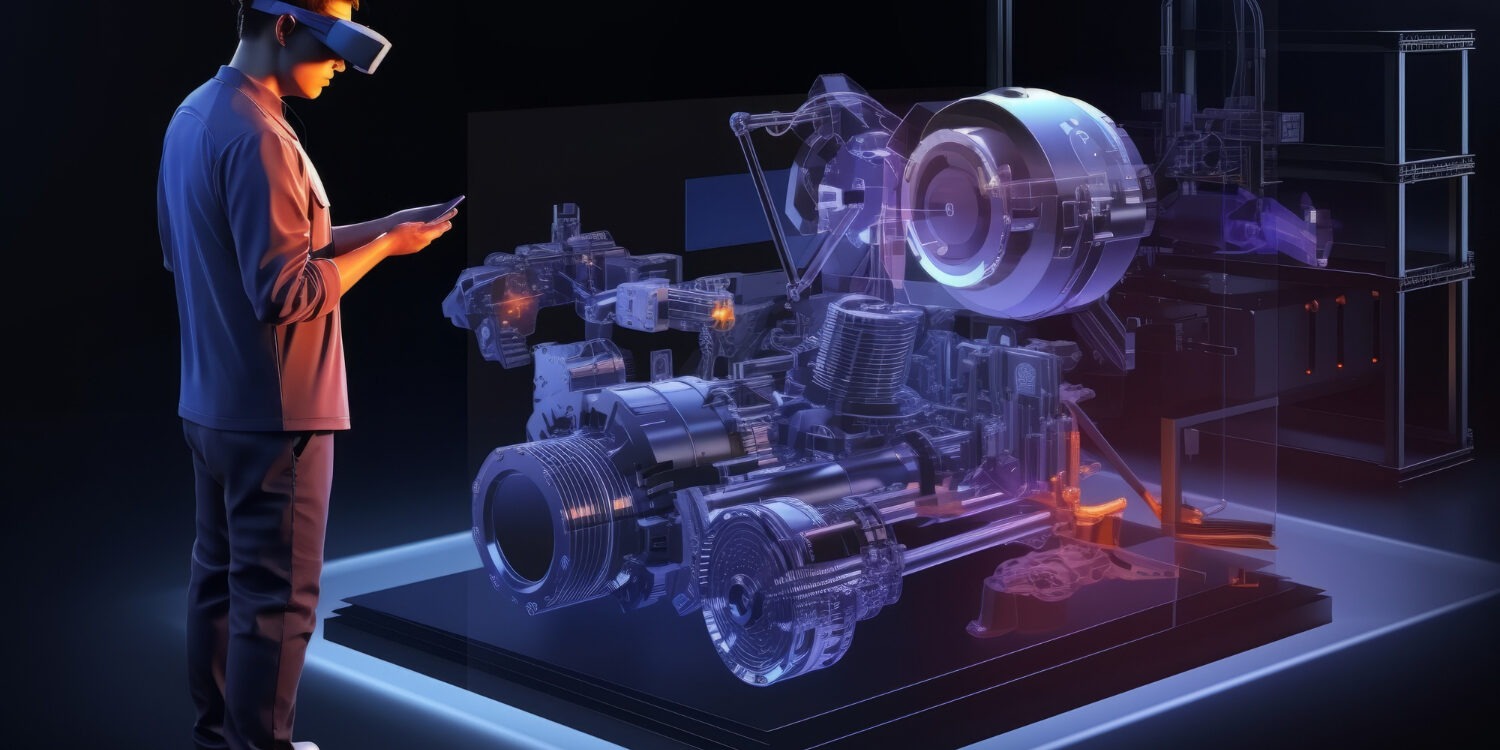

Siemens CAM (Computer-Aided Manufacturing) is a crucial tool for industries focused on product development and manufacturing processes. By automating parts of the production chain, Siemens CAM enables precision, efficiency, and scalability. This guide will walk you through the key aspects of Siemens CAM, including how it integrates with NX CAM, and why it's a valuable choice for manufacturers.

What is Siemens CAM?

Siemens CAM is a robust suite of tools designed to help manufacturers streamline their processes from product design to production. It integrates advanced technology to handle tasks such as machining, tooling, and quality control, making it suitable for various industries like aerospace, automotive, and machinery.

This software solution is part of Siemens' broader Digital Industries Software, offering manufacturers an edge in precision and automation. One of its most significant advantages is how it interfaces with NX CAM, which is Siemens' dedicated solution for advanced manufacturing.

Understanding NX CAM

NX CAM is the specific module within Siemens' software ecosystem focused on generating and controlling tool paths for CNC (Computer Numerical Control) machining. It ensures that designs created in CAD (Computer-Aided Design) systems are translated efficiently into manufacturing instructions.

NX CAM offers several key features:

Multi-axis machining: Supports 3, 4, and 5-axis machining, which allows for complex part creation.

High-speed machining: Minimizes cycle time and improves surface quality.

Automation features: Allows for templates and reusable processes, reducing manual efforts.

Whether you're working on simple parts or complex components, NX CAM is built to handle varying levels of intricacy with ease.

Benefits of Siemens CAM for Manufacturers

Increased Efficiency: Siemens CAM reduces the time spent on manual setups and programming by automating large parts of the production process. It supports multi-axis machining, which improves overall machine utilization and throughput.

Improved Accuracy: With features like machine simulation and collision detection, Siemens CAM ensures high-quality machining with fewer errors. This results in more accurate products and less rework.

Seamless Integration with NX: As part of Siemens' comprehensive software suite, NX CAM works seamlessly with other Siemens PLM (Product Lifecycle Management) software. This means that manufacturers can move from the design stage to manufacturing without having to worry about compatibility issues.

Customization: Siemens CAM allows manufacturers to tailor the system to their specific needs. From custom tool paths to specialized machining strategies, it can handle various manufacturing requirements.

Why Choose Siemens CAM?

When it comes to selecting a CAM system, Siemens stands out for its versatility, reliability, and ability to adapt to industry-specific challenges. Its integrated features within NX CAM give manufacturers the confidence to tackle complex projects with fewer errors and less downtime.

At CJ Tech, we offer the full range of Siemens CAM solutions, ensuring that your manufacturing needs are met with precision and efficiency. Whether you're looking to upgrade your current setup or are new to CAM systems, Siemens provides scalable solutions to match your requirements.

Conclusion

Siemens CAM, with its robust capabilities and integration with NX CAM, offers manufacturers a comprehensive tool for automating and improving their production processes. By utilizing Siemens CAM, industries can enjoy better efficiency, accuracy, and customization options to meet their unique demands.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.