Thermal Spray Coating Equipment Market: Key Players, Technologies and Growth Projections

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

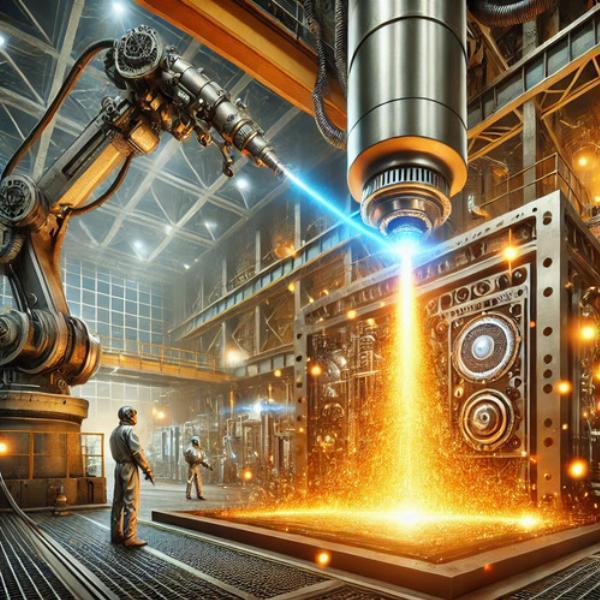

The Thermal Spray Coating Equipment Market is gaining significant momentum due to its wide applications across various industries, including aerospace, automotive, energy and healthcare. This article provides an in-depth overview of the key players, technologies driving the market, and growth projections for the thermal spray coating equipment market.

Introduction to Thermal Spray Coating Equipment

Thermal spray coating is a surface engineering process where a heated material, in the form of powder or wire, is sprayed onto a surface to provide protective coatings. These coatings enhance the wear, corrosion and heat resistance of the base material, extending the lifecycle of components.

The market for thermal spray coating equipment is expanding rapidly, driven by the need for more durable materials in industries like aerospace, automotive and manufacturing.

Key Players in the Market

Several companies are at the forefront of the thermal spray coating equipment market, offering cutting-edge technologies and innovative solutions. Some of the major players include:

Oerlikon Metco: A leader in thermal spray technology, Oerlikon Metco offers a comprehensive range of thermal spray coating equipment and materials, focusing on aerospace and power generation industries.

Praxair Surface Technologies: Known for its advanced coating solutions, Praxair specializes in high-performance thermal spray systems used in various sectors including aerospace, energy, and healthcare.

Flame Spray Technologies (FST): FST develops and manufactures thermal spray equipment and coatings for industrial applications, focusing on sustainability and eco-friendly technologies.

Metallisation Ltd: With a strong presence in the automotive and aerospace sectors, Metallisation Ltd offers a wide range of thermal spray equipment, including arc spray, flame spray, and plasma spray systems.

GTV Verschleißschutz GmbH: A key player in Europe, GTV offers advanced thermal spray equipment and is known for its focus on research and development in coating technologies.

Technologies Driving the Market

Thermal spray coating technologies have evolved significantly over the years. The following are the primary technologies driving the market:

Plasma Spray: Plasma spray technology uses a high-temperature plasma to melt materials and spray them onto surfaces. This method is highly versatile and is used for applying coatings in the aerospace, automotive, and healthcare sectors.

HVOF (High-Velocity Oxygen Fuel): This technique involves the combustion of fuel gases to generate a high-velocity stream of molten particles. HVOF coatings are popular for their excellent bond strength and wear resistance, making them ideal for heavy-duty applications.

Flame Spray: This method involves melting a material using an oxy-fuel flame and spraying it onto the substrate. Flame spray coatings are cost-effective and are often used for corrosion protection.

Cold Spray: Unlike traditional thermal spray methods, cold spray does not melt the material. Instead, it uses high-velocity gas to accelerate the particles onto the surface. Cold spray technology is highly effective for applications that require minimal thermal impact, such as in electronics.

Electric Arc Spray: This technique uses an electric arc to melt materials, which are then atomized by a stream of gas and sprayed onto the surface. It is commonly used for corrosion protection and component repairs.

Market Growth Projections

The global Thermal Spray Coating Equipment Market is expected to experience robust growth in the coming years. Several factors contribute to this projection:

Aerospace Industry Expansion: With increasing aircraft production and maintenance, the aerospace industry is one of the largest consumers of thermal spray coatings. These coatings are crucial for engine components and turbine blades that operate under extreme temperatures and wear conditions.

Automotive Industry Advancements: The automotive sector is embracing thermal spray coatings for critical engine components, exhaust systems and brake discs to improve performance and durability. The shift towards electric vehicles (EVs) is also driving demand for advanced coating technologies to enhance energy efficiency.

Healthcare Sector Growth: Thermal spray coatings are increasingly being used in the healthcare industry for medical implants and devices. The biocompatibility and corrosion resistance offered by these coatings make them ideal for orthopedic and dental implants.

Power Generation Sector: The energy sector, especially power generation, heavily relies on thermal spray coatings for turbines, boilers, and other high-performance components. With the transition to cleaner energy sources, the demand for advanced coating technologies is expected to rise.

Emerging Economies: Rapid industrialization in emerging economies such as China, India, and Brazil is boosting the demand for thermal spray coating equipment. Infrastructure development and an expanding manufacturing base in these regions provide significant growth opportunities for market players.

Challenges and Opportunities

Despite the positive outlook, the thermal spray coating equipment market faces several challenges, including:

High Initial Investment: Thermal spray coating equipment requires significant capital expenditure, which can be a barrier for small and medium-sized enterprises (SMEs).

Environmental Concerns: Some traditional thermal spray processes generate waste and emissions, posing environmental challenges. However, innovations in eco-friendly coatings and equipment are addressing these concerns.

Skilled Workforce Shortage: The need for highly skilled technicians to operate thermal spray equipment and ensure precision in coating applications is a limiting factor. Investment in training and education is essential to overcome this challenge.

On the flip side, the market presents significant opportunities for growth:

Technological Advancements: The continuous development of new materials, including ceramic and composite coatings, is opening up new avenues for thermal spray applications across industries.

Sustainability Initiatives: As industries focus on sustainability and reducing their environmental footprint, the demand for thermal spray coatings that offer longer product life and reduced material waste is expected to grow.

Conclusion

The Thermal Spray Coating Equipment Market is set to experience substantial growth due to its applications in high-performance industries such as aerospace, automotive, healthcare and power generation. Key players are innovating new technologies to meet the increasing demand for durable, corrosion-resistant, and high-temperature-resistant coatings. While challenges like high costs and environmental concerns exist, the market's future looks promising with opportunities for sustainable and advanced coating solutions.

As industries continue to push the boundaries of performance and durability, the role of thermal spray coating equipment will be integral to their success.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.