Top Advantages of Using Pneumatic Grease Pumps in Heavy Machinery Repair

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

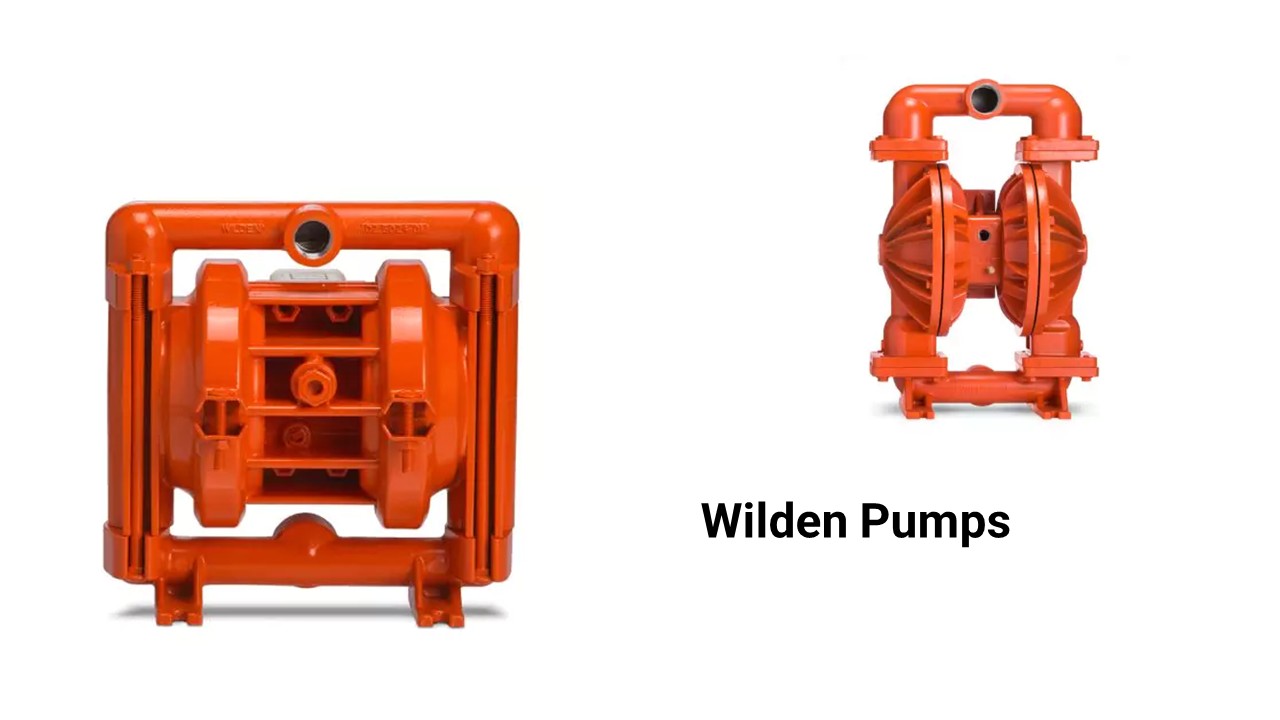

Heavy machinery repair has benefited immensely from the implementation of pneumatic grease pumps. The transfer of fluid in the most diverse applications needs to be as accurate as possible, be they manufacturing or automotive repair. Ali Yaqoob supplies the complete pumping solution line, including piston pumps, pneumatic pumps, and pneumatic grease pumps, according to heavy-duty operating conditions. Detailed discussions regarding all such technologies and applications have been mentioned below.

Piston Pumps: Accuracy and Power

Piston Displacing Pumps are a type of positive displacement pump where a reciprocated piston in a cylinder is used to displace gases or fluids. Despite delivering high pressure within a flowing stream, piston pumps find applications involving repeated and reliable operation. They can move an extremely wide spectrum of media, including viscous liquids and liquids that contain solid particles, so they are generally highly versatile.

They include various types of piston pumps:

Lift Pumps: Suck the fluid in lower cylinder during the upstroke and discharge on the subsequent upstroke.

Force Pumps: Suck fluid during upstroke and discharge during downstroke.

Single-acting and Double-acting Pumps: Single-acting ones move the fluid in a single direction per stroke, while double-acting ones move the fluid in two directions, which makes them efficient.

Strength and ruggedness of piston pumps make them ideal for heavy industry applications, i.e., water supply systems, chemical process systems, etc.

Pneumatic Pumps: Tap the Power of Air

Operation of pneumatic pumps relies on compressed air or gas to power liquids and offer a clean, efficient alternative to electrically driven pumps. Pumps are especially handy where electric sparks can be hazardous or whenever air-powered convenience is needed.

Unique features of pneumatic pumps are:

Double-acting Mechanism: The majority of pneumatic pumps incorporate a double-piston mechanism, providing smooth fluid movement and increased power.

Versatility: Pneumatic pumps find applications in transferring fluids of different nature, i.e., viscous fluids, and are available in various sizes as per different industrial requirements.

Components: Components of a simple pneumatic pump include an air compressor, pump casing, piston or diaphragm, and directional flow control valves.

Pneumatic pumps also find usage overwhelmingly in chemical processing, oil and gas industries, and manufacturing for the advantage that they present through providing safety and reliability in working under risky situations.

The Pneumatic Grease Pump: Precision Lubrication

One of the advanced applications of pneumatic pump technology is the pneumatic grease pump, utilized for precise and effective grease dispensing, mostly in motor repair and manufacturing. Compressed air drives such pumps to provide the pressure required for grease dispensing from a reservoir vessel to an application point.

Components commonly used are:

Air Motor: Translates compressed air into mechanical energy to drive the pump.

Pump Body and Grease Reservoir: Holds the internal mechanisms and grease.

Inlet/Outlet Ports and Pressure Relief Valve: Allows safe, controlled dispensing and protection against over-pressurization.

Pneumatic grease pumps offer reliable lubrication, reducing wear and maximizing machinery and vehicle life.

Conclusion

Ali Yaqoob has an extensive line of piston pumps, pneumatic pumps, and pneumatic grease pumps that offer high-duty, efficient, and effective solutions to lubrication and fluid handling. If your application requires high-pressure reliability from a piston pump, on the other hand, Ali Yaqoob has state-of-the-art pneumatic equipment that is engineered for performance and reliability pneumatic grease pump provides accurate injection of lubricant pneumatic grease pump injects lubricant correctly. Explore their whole range on their official website and select the perfect pump for your application

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.