Underlay Stitch For Embroidery And Digitizing

Embroidery digitizing is not just about creating beautiful designs; it's also about ensuring those designs stitch out perfectly on fabric. One of the critical elements in achieving high-quality embroidery is the underlay stitch. In this comprehensive guide, we'll delve into everything you need to know about underlay stitches, their importance in embroidery digitizing, and how embroidery digitizing services utilize them to enhance your designs.

Understanding Underlay Stitches

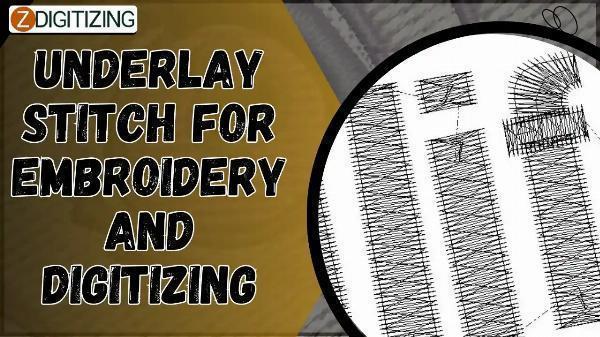

What are Underlay Stitches?

Underlay stitches are the foundation of an embroidery design. They are the first set of stitches laid down on the fabric before the main design begins. Their primary purpose is to stabilize the fabric, prevent distortion, and provide a smooth base for the top stitches.

Types of Underlay Stitches

There are several types of underlay stitches, each serving a specific purpose:

Running Stitch Underlay: This is the most basic type of underlay, consisting of straight stitches that run along the length of the design. It helps stabilize the fabric and is suitable for lighter designs.

Zigzag Stitch Underlay: Zigzag underlay stitches crisscross over the design area, providing more stability and support. They are commonly used for medium to heavy designs or fabrics that require extra reinforcement.

Grid Stitch Underlay: Grid underlay stitches create a grid pattern across the design area, offering comprehensive support and stabilization. They are ideal for larger or more intricate designs.

Fill Stitch Underlay: Fill stitch underlay consists of solid fill stitches that cover the entire design area. This type of underlay provides maximum stability and is often used for dense designs or fabrics prone to shifting.

Importance of Underlay Stitches in Embroidery Digitizing

Ensuring Design Stability

By stabilizing the fabric, underlay stitches prevent it from puckering or stretching during the digitizing embroidery service process. This stability is crucial for maintaining the integrity and shape of the design.

Improving Stitch Quality

Underlay stitches create a smooth surface for the top stitches to lay on, resulting in cleaner lines, sharper edges, and overall better stitch quality. They reduce the risk of thread breaks and ensure consistent embroidery results.

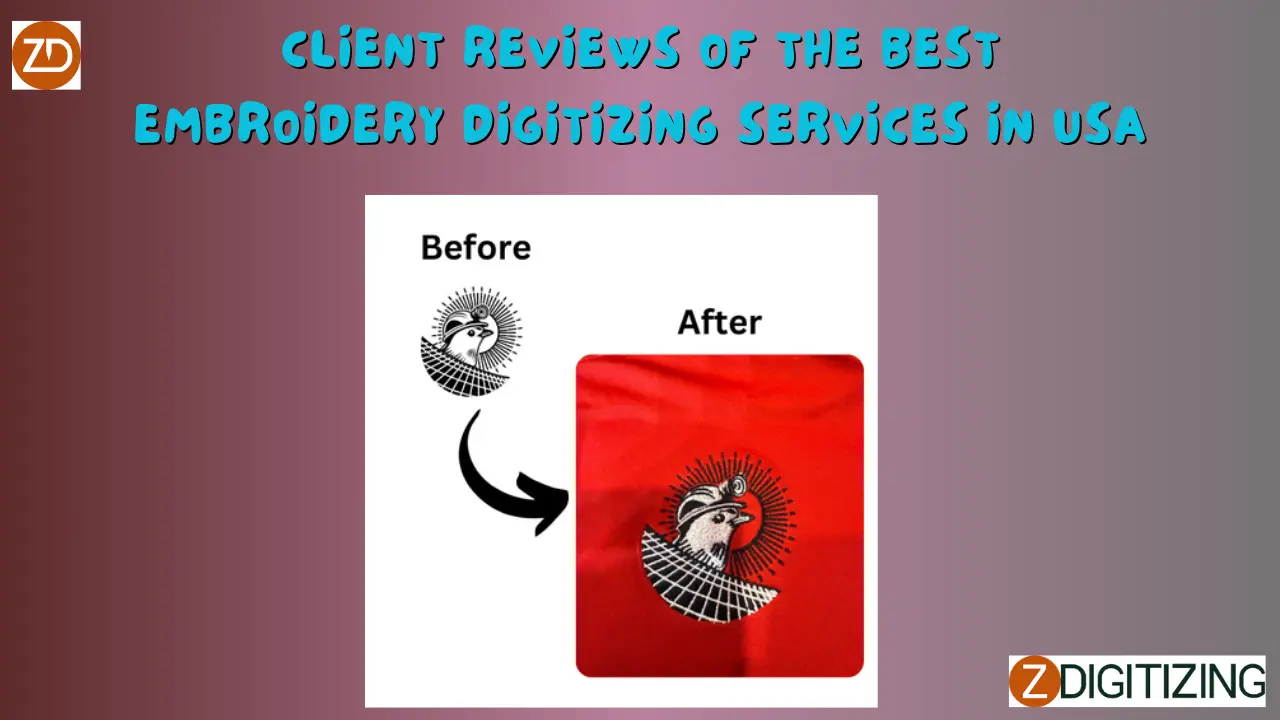

Utilizing Underlay Stitches in Embroidery Digitizing Services

Role of Professional Digitizers

Professional embroidery digitizing services understand the importance of underlay stitches in achieving high-quality embroidery. They use advanced software and expertise to determine the appropriate type and density of underlay for each design.

Customizing Underlay Stitches

Digitizing services tailor underlay stitches to suit the specific requirements of each design and fabric type. They consider factors like design complexity, fabric stretchiness, and desired embroidery effect to optimize underlay placement and density.

Best Practices for Using Underlay Stitches

1. Analyzing Design Complexity

Complex designs may require different types of underlay stitches in various sections to ensure stability and clarity. Digitizers analyze the design thoroughly to determine the most suitable underlay strategy.

2. Adjusting Underlay Density

The density of underlay stitches should be adjusted based on the fabric type and design complexity. Lighter fabrics may require lighter underlay, while heavier fabrics or dense designs may need denser underlay for optimal results.

3. Testing and Iteration

Before final production, it's essential to test the digitized design on sample fabric. This allows digitizers to identify any issues with underlay placement or density and make necessary adjustments for optimal embroidery quality.

Common Challenges in Using Underlay Stitches

1. Over-Stabilization

Excessive underlay stitches can cause the fabric to become too stiff or bulky, affecting the drape and feel of the finished embroidery. Balancing stabilization with fabric characteristics is key to avoiding over-stabilization.

2. Under-Stabilization

Insufficient underlay stitches may lead to poor stitch quality, including puckering, gaps, or uneven lines. Understanding fabric stretch and design complexity helps prevent under-stabilization issues.

Conclusion

Underlay stitches are the unsung heroes of embroidery digitizing, providing essential stability and enhancing the quality of embroidered designs. By understanding their role, utilizing professional digitizing services for embroidery, and following best practices, you can ensure that your embroidered creations are not only visually stunning but also durable and consistent. Whether you're a beginner or seasoned digitizer, mastering underlay stitches is key to achieving embroidery perfection.

FAQs

1. What are underlay stitches in embroidery digitizing?

Underlay stitches are the foundational stitches laid down before the main embroidery design begins. They stabilize the fabric, prevent distortion, and provide a smooth base for top stitches.

2. Why are underlay stitches important in embroidery?

Underlay stitches ensure design stability, improve stitch quality, and prevent fabric distortion during the embroidery process. They contribute to cleaner lines, sharper details, and overall better embroidery results.

3. How do professional embroidery digitizing services use underlay stitches?

Professional digitizers customize underlay stitches based on design complexity, fabric type, and desired embroidery effect. They use advanced software and expertise to optimize underlay placement and density for high-quality results.

4. What types of underlay stitches are commonly used in embroidery?

Common types of underlay stitches include running stitch, zigzag stitch, grid stitch, and fill stitch. Each type serves a specific purpose in stabilizing the fabric and supporting the embroidered design.

5. How can I avoid issues with underlay stitches in embroidery digitizing?

To avoid issues with underlay stitches, analyze design complexity, adjust underlay density based on fabric type, and conduct testing on sample fabric before final production. This ensures optimal embroidery quality and consistency.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.