Understanding CAD Modeling Approaches in SolidWorks: Cross-Section vs. Features

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

When it comes to creating parts in CAD software like SolidWorks, designers often dive straight into modeling without giving enough thought to the best way to approach the task. However, planning and strategizing before creating a CAD model can lead to faster creation, easier editing, and better alignment with manufacturing processes. In SolidWorks training online, the words “model” and “part” are used interchangeably.

Key Factors for a Good Modeling Plan

A modeling plan is considered effective when it meets the following:

Fastest time to create the part

Ease of editing the part later

Alignment with how the part will be manufactured

These strategies are deeply discussed in any professional SolidWorks online course, helping learners build the right mindset from day one.

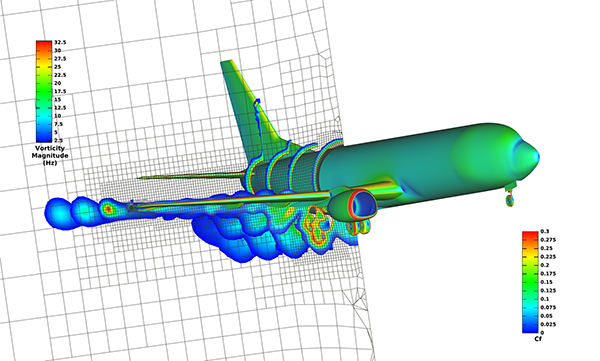

615ae7e19a93ec8e0de40ddf7b38efa8.png

Two common approaches are used in modeling: the cross-section approach and the features approach.

Cross-Section vs. Features Approach

Cross-Section Approach: This is generally quicker. You sketch the entire part profile and extrude it in one go. However, it might be harder to edit later if changes are needed.

Features Approach: This method builds the part step by step, like creating a block, chamfer, and hole. It mirrors how a machinist would make the part in real life, starting from a block and then working step-by-step. While it may take longer initially, it’s more modular and easier to modify.

Many SolidWorks online classes explain both these approaches in depth with examples. Whether you're attending SolidWorks training online or self-learning through videos, understanding both styles is a must.

For example, take a chamfered block with a hole. In the cross-section approach, the sketch would include all the features (like the chamfer and the hole) in one sketch. In the features approach, you would first create a solid block, then apply a chamfer, and finally create the hole. Each of these is done as a separate feature.

Personal preferences and industry experience often influence this debate between speed and modularity. Designers with a manufacturing background may lean toward the features approach because it better reflects how parts are made in the real world.

Creating a Part in SolidWorks

Once you’ve chosen your modeling strategy, the next step is to use a CAD/CAM system like SolidWorks to create the part. This is a major part of what SolidWorks classes online focus on for beginners and intermediate learners.

SolidWorks builds a part using features. A feature can be an extrusion, a hole, or a revolve. When you add a feature, it combines with existing features to build the full 3D part. Each new addition updates the model in the feature tree.

Basic Features in SolidWorks:

Extrusion: Creates a shape with uniform thickness.

Revolve: Creates a shape by revolving a 2D sketch around an axis.

The feature creation process begins with a 2D sketch. You sketch the profile on a selected sketch plane and then use it to create a 3D feature.

SolidWorks provides two tabs: the Sketch tab and the Features tab. You can start from either tab, but starting from the Features tab is often considered more efficient because it automatically guides you into sketching mode.

Example Walkthrough

Let’s look at a simple plate example:

Create Sketch1: Select Top Plane > Use Center Rectangle > Smart Dimension for sizing > Exit sketch.

Create Block Feature: After exiting, enter the thickness (e.g., 0.5) and finish. Rename the node to “Block” and save the file.

Add Hole Feature: Select the top face of the block > Extruded Cut > Draw a circle from the origin > Dimension it (e.g., diameter 1) > Enter thickness (0.5) and finish. Rename the node to “Hole.”

544d918904cc97389098d8075caf3037.png

04e6e2aead11b5d1e3c5ef0f9fd7c801.png

This step-by-step approach mirrors what’s covered in SolidWorks training online, making complex parts easy to build.

Conclusion

In summary, the choice between the cross-section and features approach in CAD modeling depends on your goals—speed or flexibility. For educational purposes, especially in SolidWorks online class modules, using the features approach helps learners understand part creation more deeply by breaking it into manageable steps.

If you’re looking to build your skills in SolidWorks and learn both these modeling approaches with hands-on practice, check out the SolidWorks training course online. It's a great way to strengthen your CAD knowledge and get industry-ready.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.