Understanding the HFF Heat Exchanger: Design, Applications, and Benefits

The HFF Heat Exchanger is a critical component in many business procedures, designed to effectively transfer heat between two fluids. This form of warmness exchanger is extensively applied in numerous sectors because of its sturdy design and capability to cope with excessive temperatures and pressures. As an important product frequently supplied by a business merchandise manufacturer, the HFF Heat Exchanger performs a widespread function in enhancing power performance and optimizing thermal management in systems.

What is an HFF Heat Exchanger?

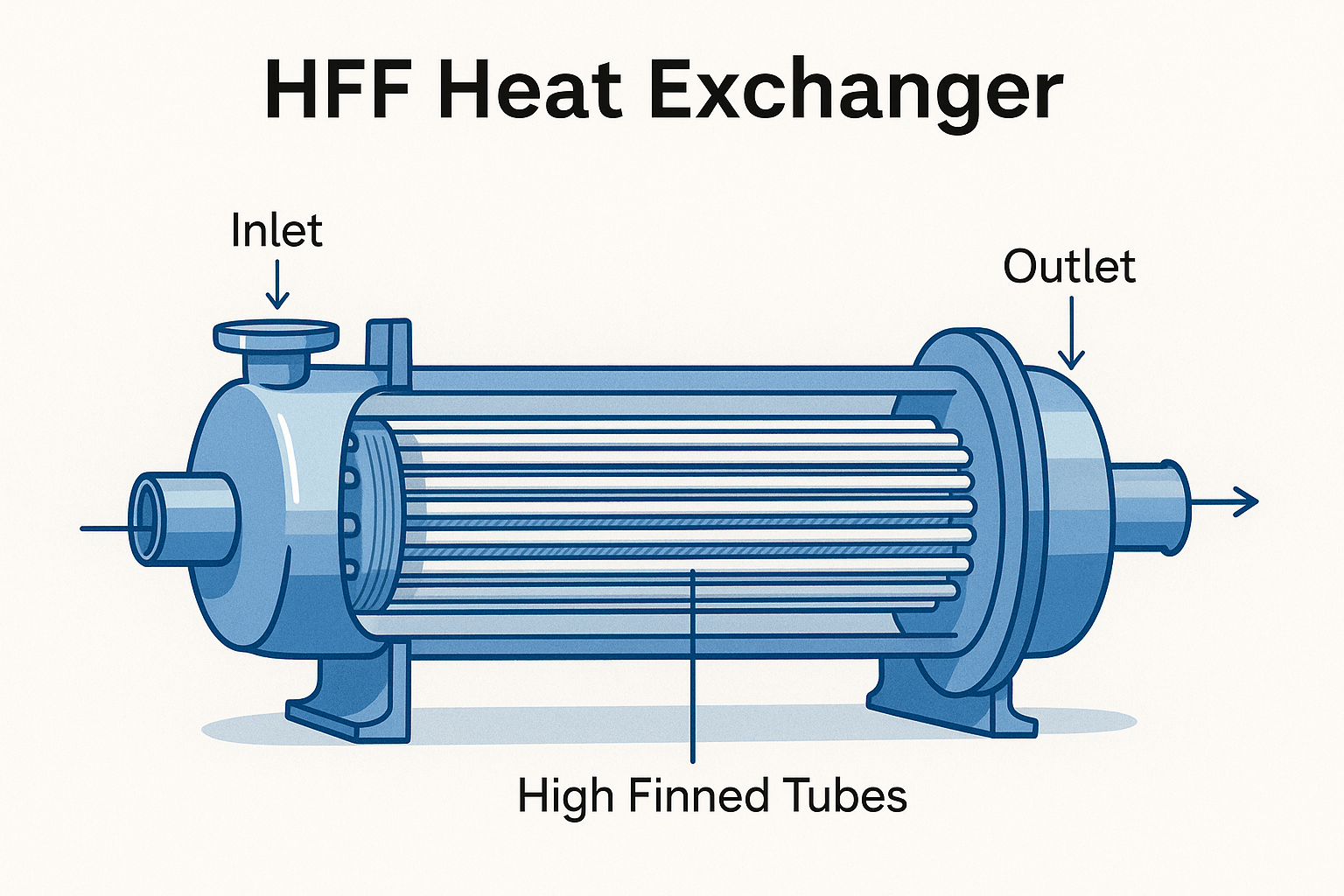

The HFF Heat Exchanger is a specialised heat switch device that uses a combination of finned tubes and shell-and-tube production to maximize the floor place for warmth alternate. Unlike conventional warm temperature exchangers, the HFF design consists of high-performance fins related to the tubes to growth thermal conductivity and heat switch charge. This results in progressed performance, especially in programs requiring compact designs or handling fluids with varying temperature tiers.

The acronym "HFF" stands for "High Fin Finned," highlighting the importance of the finned surfaces on this warmness exchanger type. The fins are generally crafted from materials with superb thermal conductivity, consisting of aluminum or copper, permitting warmth to transport hastily from the tube wall to the encircling fluid or vice versa.

Key Components and Design Features

The important components of an HFF Heat Exchanger encompass the shell, tubes, fins, and end plates. The tubes carry one of the fluids, at the identical time as the opposite fluid flows across the tubes in the shell. The fins, which is probably consistent on the outside surface of the tubes, dramatically boom the ground area to be had for heat transfer. This layout permits efficient warmth exchange no matter confined space or low drift velocities.

The shell commonly has nozzles for fluid access and go out, and the entire meeting is constructed to face as much as commercial pressures and temperatures. The tube bundle deal, with fins, is removable in lots of designs, allowing much less complicated protection and cleansing. This modular issue is a considerable benefit in business settings in which downtime needs to be minimized.

How the HFF Heat Exchanger Works

Heat change within the HFF Heat Exchanger takes place through conduction and convection. One fluid flows in the tubes at the same time because the alternative fluid passes over the finned surfaces. Heat is conducted thru the tube wall and fins after which transferred to the fluid outdoor the tubes. The fins boom the convective warmth transfer coefficient through enlarging the heat switch floor, this is particularly useful while one fluid is a gasoline with low thermal conductivity.

This dual mechanism ensures that even fluids with bad warmth transfer houses can be processed efficaciously. The fin format additionally allows lessen fouling and improves warmth exchanger sturdiness thru retaining effective warmth transfer over the years.

Applications of HFF Heat Exchangers in Industry

HFF Heat Exchangers discover large software at some point of multiple industries, including chemical processing, energy era, HVAC structures, and petrochemicals. Their potential to cope with large temperature versions and immoderate-stress environments makes them best for important approaches.

In chemical plants, they're used for heating or cooling reactive fluids. Power flowers make use of those exchangers to recover waste warmth, improving trendy power performance. HVAC systems enjoy the compactness and immoderate thermal switch charge of the HFF design, which permits green aircon and ventilation.

Moreover, commercial enterprise products manufacturers often tailor these warmth exchangers to fulfill unique way requirements, making sure high-quality typical performance and sturdiness underneath tough running conditions.

Advantages of Using HFF Heat Exchangers

One of the number one blessings of the HFF Heat Exchanger is its excessive warmth transfer efficiency. The finned tubes maximize the floor place, permitting better thermal performance in a smaller footprint in comparison to standard warmness exchangers.

Another benefit is durability. The production substances and layout can resist competitive running environments, inclusive of corrosive fluids and excessive temperatures. This durability reduces maintenance prices and increases uptime for commercial techniques.

Furthermore, the modular design permits smooth cleansing and protection, that's important in industries in which device fluids can purpose fouling or scaling on warmth switch surfaces.

The HFF Heat Exchanger also offers versatility. It can be customized for first-rate fluids, pressures, and temperature levels, making it suitable for a widespread type of programs without compromising overall performance.

Factors to Consider When Choosing an HFF Heat Exchanger

Selecting the proper HFF Heat Exchanger depends on numerous elements, consisting of the types of fluids worried, temperature degrees, strain conditions, and the desired warmness switch capacity. The physical place to be had for installation can also affect the choice, as HFF gadgets are frequently desired whilst compact size is a concern.

Material compatibility is any other vital attention. Since industrial fluids can be corrosive or abrasive, the materials for tubes, fins, and shell ought to be decided on as a consequence to save you premature failure.

Efficiency requirements will decide the fin layout and density, in addition to the tube diameter and length. An business merchandise manufacturer typically works closely with clients to design an exchanger tailor-made to unique approach needs, balancing performance, fee, and upkeep factors.

Maintenance and Operational Considerations

Maintaining an HFF Heat Exchanger includes normal inspection and cleansing to prevent fouling and corrosion, that may considerably reduce heat transfer efficiency. The finned tubes have to be checked for damage for the purpose that bent or damaged fins can impair thermal general performance.

Operational parameters together with fluid float charges and temperatures need to be monitored to make certain they remain in the layout specs. Deviations can result in mechanical stress or thermal fatigue, reducing the unit's lifespan.

Proper upkeep exercises enlarge the company existence of the exchanger and keep most appropriate ordinary performance, thereby assisting the overall reliability of commercial enterprise operations.

Future Trends in HFF Heat Exchanger Technology

Advancements in materials technological understanding and production strategies preserve to enhance the overall performance of HFF Heat Exchangers. New fin designs using additive production (three-D printing) are being explored to create optimized fin geometries that enhance warmness transfer while decreasing weight.

There is also a growing attention on integrating smart sensors for actual-time monitoring of heat exchanger conditions. These sensors can encounter fouling, corrosion, or temperature anomalies early, allowing predictive renovation and decreasing sudden downtime.

Sustainability is another important fashion. Designing exchangers for power performance and recyclability aligns with broader commercial desires to reduce environmental impact.

Conclusion

The HFF Heat Exchanger remains a crucial generation in plenty of commercial enterprise sectors because of its green format, high thermal performance, and flexibility. With functions like more proper surface vicinity via finned tubes and robust manufacturing, it meets the traumatic goals of current-day enterprise methods. Working with a skilled commercial industrial products manufacturer ensures that every HFF Heat Exchanger is customized to unique applications, maximizing operational performance and reliability.

Understanding the essential going for walks principles, packages, and protection requirements of the HFF Heat Exchanger permits industries make knowledgeable choices for thermal control solutions that enhance productivity and energy use. As enhancements keep, the feature of HFF Heat Exchangers will best increase, assisting increasingly more state-of-the-art industrial goals.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.