Conversion-Focused Landing Pages – More Leads, Less Bounce!

Conversion-Focused Landing Pages – More Leads, Less Bounce!

Unlocking the Potential: Applications & Manufacturing of HDPE (2023–2035)

Written by ChemAnalyst Data » Updated on: June 17th, 2025 425 views

High-Density Polyethylene (HDPE), an omnipresent plastic polymer, serves as a cornerstone in numerous global industries. Renowned for its adaptability, resilience, and economical nature, High-Density Polyethylene (HDPE) stands as a preferred material across diverse applications. In this comprehensive blog, we aim to explore the expansive realm of High-Density Polyethylene (HDPE), shedding light on its inherent characteristics, extensive utilization, and ecological implications. With a global demand of nearly 40.8 million tonnes in 2023, the global High-Density Polyethylene (HDPE) market is likely to flourish with a CAGR of 5.2% expected until 2034.

Introduction

High-Density Polyethylene (HDPE) has become indispensable in modern industry due to its exceptional versatility and eco-friendly attributes. Across various sectors, HDPE offers a wide range of applications while prioritizing environmental sustainability. In packaging, HDPE has transformed the storage and presentation of products, thanks to its lightweight yet durable nature. It is commonly used for bottles, containers, and packaging films, ensuring product protection with minimal environmental impact. Additionally, HDPE's resistance to moisture, chemicals, and temperature variations makes it suitable for diverse packaging needs, spanning food, beverages, pharmaceuticals, and personal care products. In the construction industry, HDPE plays a crucial role in developing robust infrastructure. Its corrosion resistance, low maintenance requirements, and long lifespan make it ideal for pipes, fittings, and insulation materials, contributing to the construction of sustainable structures.

HDPE plastics offer a cost-effective solution for producing high-quality finished goods. These molded products can be customized with a variety of colors and textures, including translucent and opaque options, and they have excellent printing capabilities for images, logos, and text directly on the plastic surface or via labels. Additionally, incorporating color or pigmentation can enhance the strength of the final product.

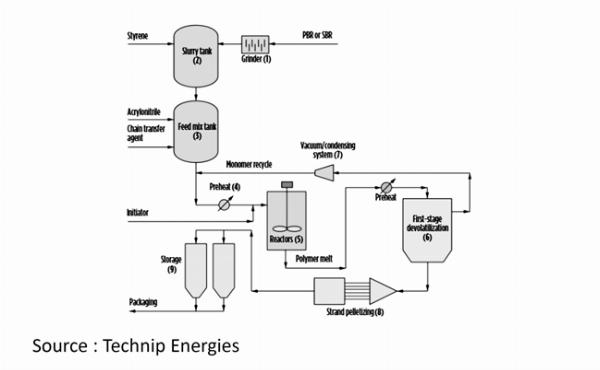

Manufacturing Process

HDPE, or High-Density Polyethylene, is produced through a multi-step process that harnesses the molecular properties of petroleum-derived hydrocarbons. Initially, these hydrocarbons undergo thermal cracking under high heat, leading to the breakdown of complex chains into simpler monomers, with ethylene being a primary target for HDPE production. Ethylene is then collected in gaseous form.

In the subsequent step, the collected ethylene gas is combined with metallic catalysts, such as titanium tetrachloride, diethylaluminum chloride, or chromium oxide on silica. These catalysts play a pivotal role in facilitating polymerization, guiding the ethylene molecules to link together in a controlled manner, forming a slurry of polyethylene.

Once the polymerization process is complete, the resulting slurry undergoes thorough cleaning to remove any residual catalysts. The purified HDPE is then separated from the solution through extraction, filtration, and drying processes, ensuring the removal of impurities and achieving the desired level of purity and quality.

Finally, the purified HDPE undergoes further processing and shaping, tailored to meet specific industry requirements.

The Spherilene process is a proprietary method utilizing a gas-phase reactor to produce high quality HDPE. At its core, this technology employs a single reactor and recirculation system. It spans a wide range of melt index and PE density. The Spherilene approach yields monomodal products such as LLDPE for film, HDPE for injection molding using Avant Z Ziegler and Avant C Chromium catalysts. What sets the Spherilene method apart is its operational stability, coupled with Avant catalysts' consistent performance. Its reactor features a unique outlet mechanism at the base, ensuring continuous and efficient product extraction with minimal gas carry-over.

Applications of High-Density Polyethylene (HDPE):

Construction: HDPE's water-resistant nature and ease of welding make it a preferred choice among pipe manufacturers. Its unique properties lend themselves well to the creation of lightweight, sturdy, and long-lasting piping systems.

Food & Beverage containers: HDPE is excellent for blow-molding applications, because it won’t leach into the bottles’ contents. Also, HDPE is recyclable in nature which makes it a great choice for these highly disposable products.

Chemical: Due to its exceptional chemical resistance and weldability, HDPE is preferred for crafting bottles, containers, and tanks designed to hold chemical substances. It is also utilized in the production of corrosion-resistant liners. HDPE exhibits compatibility with various substances, including low concentration acids, specific concentrated acids several alcohols, as well as bases and alkalis.

Market Outlook:

The global High-Density Polyethylene (HDPE) market is anticipated to reach approximately 75 million tonnes by 2035. Thanks to its remarkable flexibility, High-Density Polyethylene (HDPE) finds itself in the spotlight for a variety of applications, including the production of films and flexible packaging.. With critical applications ranging from pipes and fittings to insulation materials, HDPE is expected to continue making waves in the construction industry, further fueling the expansion of the HDPE market in the foreseeable future. Moreover, the lightweight nature of HDPE plastic makes it a viable alternative to heavier and less eco-friendly materials in numerous industrial and demanding applications. Therefore, opting for HDPE plastic can enable manufacturers to support sustainability objectives and achieve net-zero carbon targets.

High-Density Polyethylene (HDPE) Key Market players

Significant companies in the Global High-Density Polyethylene (HDPE) market are LyondellBasell Industries N.V., INEOS Olefins and Polyolefins, Nizhnekamskneftekhim JSC(NKNK), ORLEN Unipetrol, SCG Chemicals, Lotte Chemical, Chevron Phillips Chemical, Braskem SA, ExxonMobil, and Saudi Polymers Company.

Challenges and Opportunities

While the High-Density Polyethylene (HDPE) market also faces several challenges that impact its growth.

Shift Towards Other Plastics: The HDPE (High-Density Polyethylene) market faces several challenges that impact its growth and sustainability. One significant challenge is the increasing competition from alternative materials, such as polypropylene and bio-based plastics, driven by environmental concerns and regulatory pressures to reduce plastic usage. Additionally, fluctuating raw material prices, particularly those of crude oil and natural gas, which are primary feedstocks for HDPE production, pose a challenge to manufacturers in maintaining stable pricing and profitability. HDPE exhibits several drawbacks: it fares poorly in weathering conditions, poses a high flammability risk, is prone to stress cracking, lacks biodegradability and compostability, and offers limited resistance to oxidizing acids and chlorinated hydrocarbons. Additionally, it experiences high thermal expansion and struggles with temperature variations.

Conclusion:

In conclusion, HDPE stands as a versatile and robust material that plays a crucial role in numerous industries, from packaging and construction to healthcare and beyond. Its exceptional durability, chemical resistance, and recyclability make it a preferred choice for various applications, contributing to sustainability efforts worldwide. As we continue to explore innovations and advancements in polymer technology, HDPE remains at the forefront in polymer industry due to its cost-effectiveness and recyclable nature. HDPE plastic finds extensive utility across various sectors. It serves as corrosion-resistant piping and stock material, fuel tanks, and food containers like bottles, milk jugs, and cups. Additionally, it's used in personal care products, household items like trash cans and storage containers, medical equipment, 3D printing filament, boating components, cable insulators, sewage mains, and pyrotechnic elements.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.

Copyright © 2019-2025 IndiBlogHub.com. All rights reserved. Hosted on DigitalOcean for fast, reliable performance.