Vertical Laser Shaft Alignment Services In India

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

Shaft alignment is an essential aspect for machinery maintenance and better reliability. This is because; when machinery gets misalignment then it may lead to increased wear and tear, degrade efficiency and unrealistic failure. Therefore, shaft precise alignment is important to keep smooth operation of industry machinery.

My dears! Don’t worry about this; our company will do offering best Horizontal Laser Shaft Alignment Services and Vertical Laser Shaft Alignment Services to fix those machinery issues. On these laser alignment services, we use laser technology to get higher level of precision and increasing equipment lifespan.

Horizontal Laser Shaft Alignment Services

Horizontal laser shaft alignment comes in the list of essential services of well maintaining machinery and longevity of rotating machinery. Once misaligned them; it may arises higher price breakdowns, more energy consumption, and increased wear and tear.

To overcome them; you can use our premium horizontal laser shaft alignment services at reasonable price to get better performance of your machinery.

What is Horizontal Laser Shaft Alignment?

Horizontal laser shaft alignment allows adjusting the position of two attached machine shafts to get precise alignment along a horizontal axis. Misalignment can pose many concerns like as improper installation, thermal expansion, and machine settling over time.

So, horizontal laser shaft alignment services let you ensure that shafts accurately aligned to minimize stress on machine components.

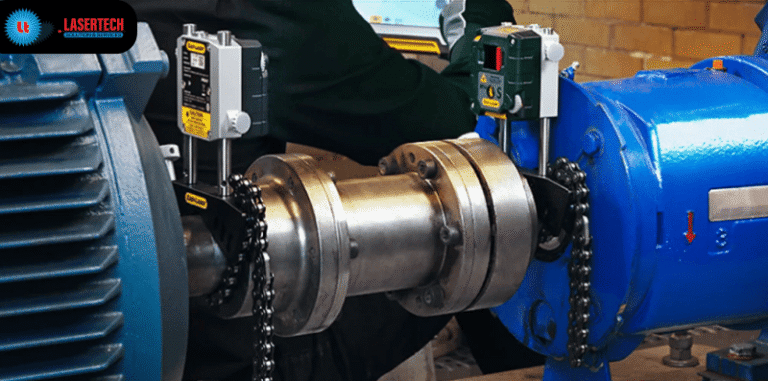

How Horizontal Laser Shaft Alignment Works?

Horizontal Laser Shaft Alignment involves many essential steps that should be performing one by one. There are:

Setup: Mount the laser transmitter and sensor on the coupling of two shafts.

Measurement: The laser beam projects a reference line across the shafts, and the sensor helps to detect the deviations from the reference.

Adjustment: Apply the real-time data to make adjustment the positions of machinery until the shaft are aligned along with specific tolerances.

Verification: Get verification of alignment by using the laser data that lets you ensure shafts positioned perfectly.

Benefits of Horizontal Laser Shaft Alignment Services

High Accuracy: Laser technology ensures precision down to micrometers.

Reduced Downtime: Quick measurement and adjustment reduce equipment downtime.

Extended Equipment Life: Proper alignment helps to decrease the stress on components and improving longevity.

Increased Efficiency: Decreased the friction and vibration enhance operational efficiency.

Lower Maintenance Costs: Well-aligned shafts let’s to minimize unexpected risk of mechanical failures.

Applications of Horizontal Shaft Alignment

- Motors and pumps

- Gearboxes

- Generators

- Compressors

- Fans and blowers

Vertical Laser Shaft Alignment Services

Vertical Laser Shaft Alignment is also a essential service that uses in industrial settings. Once done it, ensure the precise alignment of rotating machinery with vertically mounted shafts.

In vertical laser shaft alignment services; uses the advanced laser technology to measure and make adjustment the position of shafts along with high accuracy. So, it lets you ensure optimal performance and prolonged equipment longevity.

What is Vertical Laser Shaft Alignment?

Vertical Shaft Alignment is a process, where align two vertically positioned rotating shafts. And, it also ensures they are properly connected and decrease misalignment problems.

Once executed this process; prevent vibration, equipment wear, and operational inefficiency. Precision alignment helps to smooth operation, extends machinery life, and cut-off maintenance prices.

This is all part of our Laser Alignment Services in India, ensuring top-notch precision and accuracy.

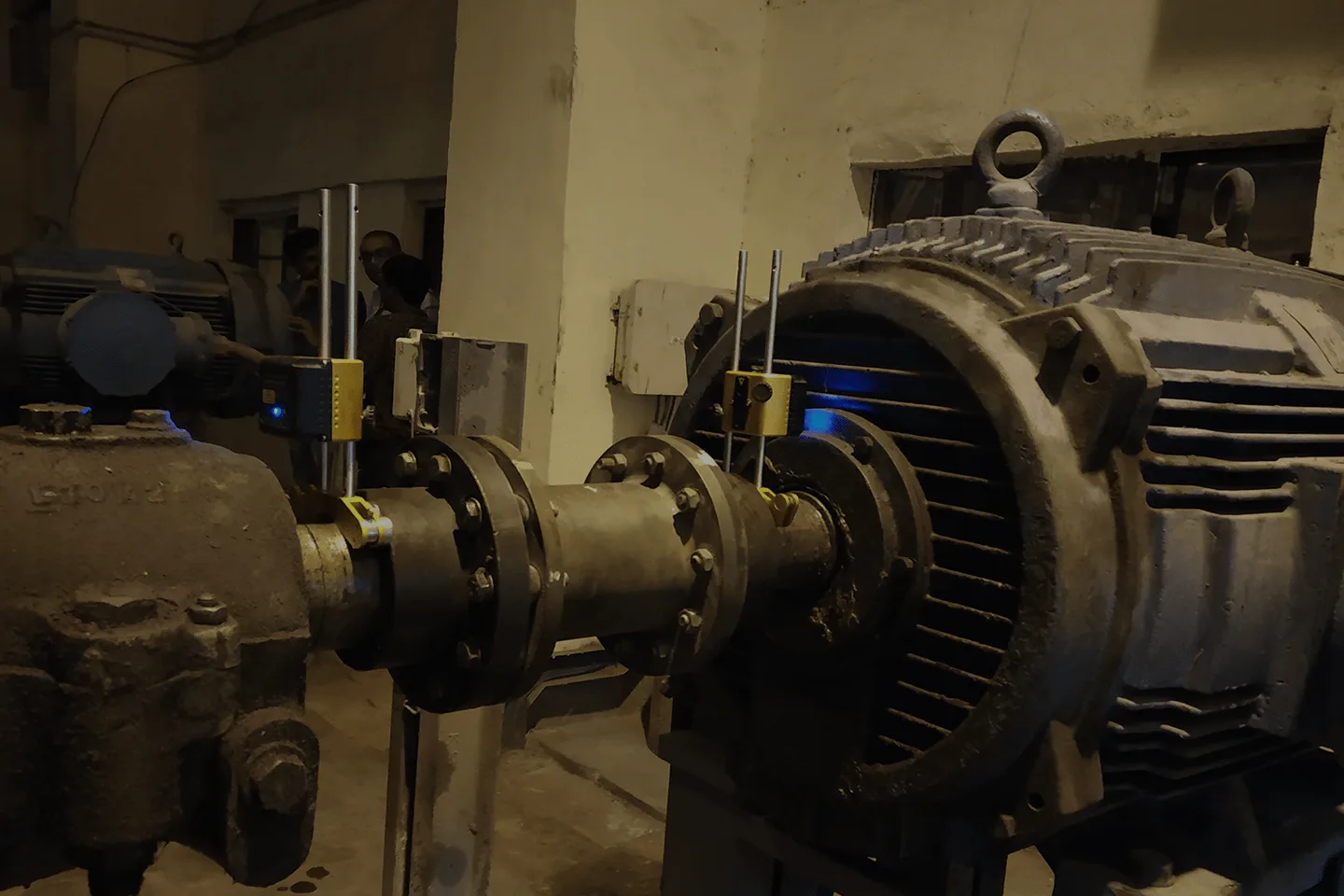

How Vertical Laser Shaft Alignment Works?

Initial Assessment: Our experts apply the laser alignment tool to assess the shaft’s position.

Measurement: The laser device sends a beam that measures angular and parallel misalignment.

Adjustment: Based on the measurements, precise adjustments are made to align the shaft vertically using shims or mechanical adjustments.

Verification: Once adjustment, the alignment is rechecked to get confirmation accurate positioning.

Benefits of Vertical Laser Shaft Alignment Services

Increased Efficiency: Perfect alignment eliminates the friction, and enhancing overall machine performance.

Cut-off Maintenance Prices: Lower wear and tear result in fewer repairs and part replacements.

Extended Equipment Lifespan: Better alignment also helps to minimize stress on components, and increasing longevity.

Improved Safety: Reduced vibration and operational strain enhance workplace safety.

Minimal Downtime: Fast and accurate alignment reduces equipment downtime, and boosting-up productivity.

Industries That Benefit from Vertical Shaft Alignment

- Power generation

- Manufacturing

- Chemical processing

- Oil and gas

- Water treatment

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.