Wafer Grinder Market Forecast: Rising Demand and Technological Advancements

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

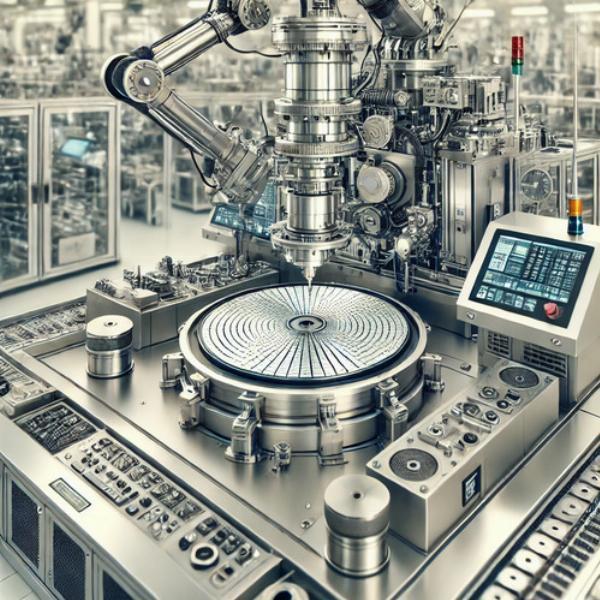

The Wafer Grinder Market is witnessing rapid growth as technological advancements and increasing demand for miniaturized, high-performance electronics fuel innovation in semiconductor manufacturing. Wafer grinding, a crucial process in semiconductor production, involves the precise thinning of wafers to achieve the desired thickness, critical for producing modern electronics such as smartphones, computers, and other compact devices. As the demand for smaller and more powerful devices continues to surge, wafer grinding technology is evolving to meet the industry's stringent requirements for precision and efficiency.

Key Drivers of Growth in the Wafer Grinder Market

Increasing Demand for Consumer Electronics: The rise of smartphones, wearables, and other compact consumer electronics is driving demand for thinner and more efficient semiconductor wafers. As consumers continue to seek smaller devices with enhanced performance, manufacturers are focusing on wafer grinding to meet these needs.

Technological Advancements: Innovations in wafer grinding technology have improved the precision and efficiency of the process, allowing for greater control over wafer thickness and surface quality. Advanced grinders with automation and AI-driven features are enabling manufacturers to achieve higher yields while minimizing defects, boosting overall productivity.

Growth of 5G and IoT: The rollout of 5G technology and the growing adoption of the Internet of Things (IoT) are creating new opportunities for semiconductor manufacturers. These technologies require advanced chips that can handle faster data processing, increased connectivity, and greater power efficiency, driving the demand for high-precision wafer grinding solutions.

Expansion of the Automotive and Aerospace Industries: The increasing use of semiconductors in automotive and aerospace applications, such as autonomous vehicles and advanced avionics systems, is contributing to the demand for wafer grinding technology. These industries require high-performance, durable chips, further driving the need for precision wafer grinding.

Market Segmentation: Types of Wafer Grinders

The wafer grinder market can be segmented based on types of machines and applications:

Wafer Edge Grinders: These machines are designed to grind the edges of the wafers, ensuring smooth and defect-free edges that prevent cracking and other damage during further processing.

Wafer Surface Grinders: Surface grinders are used to thin wafers and achieve a uniform surface across the wafer. This process is essential for reducing the overall thickness while maintaining structural integrity.

Rotary Grinders: Rotary wafer grinders offer high precision and are commonly used in large-scale production environments. They provide excellent control over the grinding process, making them ideal for applications requiring consistent and precise results.

Key Applications of Wafer Grinders

The wafer grinder market is driven by several key applications across various industries:

Semiconductor Manufacturing: Wafer grinding is a vital step in semiconductor production, ensuring the production of thin wafers for integrated circuits, microprocessors and memory devices.

LED and Optoelectronics: Wafer grinding technology is critical in the production of LEDs, optical sensors and other optoelectronic components, where ultra-thin wafers are required for efficient light emission and energy efficiency.

Advanced Packaging: The trend toward advanced packaging technologies, such as 3D packaging and system-in-package (SiP), is boosting demand for wafer grinding solutions. These technologies rely on thin wafers to achieve higher performance and integration levels.

Regional Insights

The wafer grinder market is seeing substantial growth across several regions:

Asia-Pacific: As the largest hub for semiconductor manufacturing, the Asia-Pacific region dominates the wafer grinder market. Countries like China, South Korea, Japan and Taiwan are home to leading semiconductor companies and the rapid adoption of 5G and AI technologies in this region is further boosting demand for wafer grinding solutions.

North America: The presence of major semiconductor manufacturers and advancements in consumer electronics, automotive technologies and aerospace applications are driving market growth in North America. The U.S. is a key player in the semiconductor industry, fostering innovation and investment in wafer grinding technology.

Europe: The automotive sector's growth and the increasing focus on energy-efficient electronics are driving demand for wafer grinding technologies in Europe. Germany, in particular is a significant market, given its strong presence in both the automotive and industrial electronics sectors.

Future Outlook and Market Trends

The wafer grinder market is poised for continued growth, driven by technological advancements and the increasing demand for high-performance electronics. Several key trends are expected to shape the market’s future:

Automation and AI Integration: As the semiconductor industry shifts towards smart manufacturing, wafer grinders equipped with automated systems and AI-driven analytics will become increasingly prevalent. These technologies will enable greater precision, reduce human error and optimize the grinding process, improving overall production efficiency.

Miniaturization and Advanced Packaging: The trend toward miniaturization in consumer electronics and the push for advanced packaging technologies will continue to drive demand for wafer grinding solutions that can produce ultra-thin wafers with minimal defects.

Sustainability Initiatives: As the focus on sustainable manufacturing grows, wafer grinding processes are being optimized to reduce waste and energy consumption. Manufacturers are investing in eco-friendly grinding technologies that minimize material waste and reduce environmental impact.

Conclusion

The wafer grinder market is experiencing significant growth, driven by rising demand for consumer electronics, 5G technologies and advanced semiconductor applications. As technological advancements continue to enhance the precision and efficiency of wafer grinding processes, the market is poised for further expansion. With increasing investments in automation, AI, and sustainable solutions, the future of wafer grinding looks bright, offering exciting opportunities for manufacturers, innovators and industry leaders alike.

Learn More On:

Thermal Spray Coating Equipment Market Scale

Torque Wrench Market Scale

Magnetic Bearings Market Scale

Load Bank Market Scale

Digital Refractometers Market Scale

Universal Testing Machine Market Scale

Roots Blower Market Scale

Infrared Detector Market Scale

Ship Exhaust Gas Scrubber Market Scale

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.