What Are The Uses and Applications of Gelcoat Spray Guns & Impregnation Systems

Strong 8k brings an ultra-HD IPTV experience to your living room and your pocket.

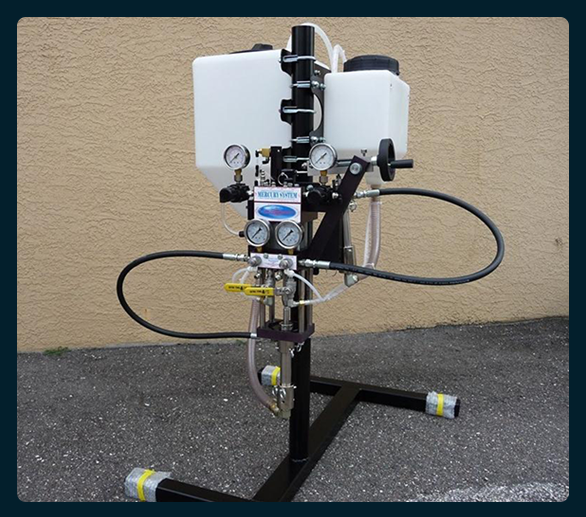

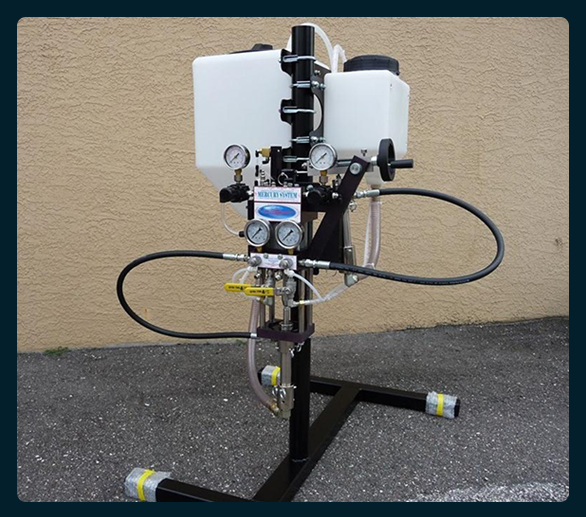

Precision and performance come first with advanced manufacturing and industrial coatings. Composite materials have transformed how substances are manufactured, consolidated, and finished-from marine applications through aerospace to automotive and construction. Companies like Phoenix Equipment are providing leading-edge solutions within this arena, offering Composites Applicators, Gelcoat Spray Guns, and Impregnation Systems-all tailored to modern industrial demands. These tools are pivotal in making applications more accurate, reducing waste, and improving material integrity.

The Role of Composites Applicators in Modern-Day Manufacturing

Composites applicators, among other things, are used for the application of resins, gelcoats, and reinforcement materials for composite manufacturing processes. Whether a process involves hand lay-up, spray-up, or resin infusion, these applicators distribute materials evenly and ensure proper saturation so that structural performance is optimized.

Depending on the system chosen, the right composite applicator not only increases the efficiency of production but also decreases waste of materials, costs in labor, and possibilities of human error. Phoenix Equipment has applicator systems for different composites including fiberglass, carbon fiber, and those using hybrid advanced reinforcements. These systems are all designed to incorporate user-friendly operation with rugged components and precise controls for consistency and durability in high-volume production environments.

Gelcoat Spray Guns: Finishing the Surface

The outermost layer for molds used in fiberglass production is called gelcoat. It is everything in providing aesthetics and protection. A good gelcoat spray gun should be able to apply finishes with proper film thickness and reasonably uniform coverage, with minimal overspray. The applications could be a hull of a boat, a sanitary fixture, or the blade of a wind turbine. All these must be appealing to the eyes and resistant against UV, water, and chemicals.

Gelcoat spray guns are built with high-efficiency atomization, flow adjustment, and ergonomic design, enabling operators to apply the gelcoat in the best possible manner in a highly efficient ergonomic manner. The latest models are also designed to reduce maintenance downtime and have very quick color changes—perfect for applications that need flexibility and speed.

Impregnation Systems: Strength from Within

Impregnation in the composites industry is the filling of the reinforcing fiber with resin (i.e., carbon or glass) for the purpose of creating a strong and coherent laminate. The impregnation process is critical as any voids, weak spots, or delamination are likely to be formed on the final product if not sufficiently or consistently impregnated.

The impregnation systems of Phoenix Equipment have been designed to effect uniform flow of resin, control pressure, and achieve optimum wet-out for all the various reinforcement materials. All such features are essential for the manufacture of high-performance components in sectors like aerospace, defense, and high-performance automotive where structural integrity is uncompromising.

This technology will ensure that all fibers are fully impregnated, resulting in stronger, lighter, and more reliable finished parts. Also, its automated monitoring and feedback features facilitate control of critical parameters, enhancing repeatability and quality assurance.

Outlook of Phoenix Equipment Being in the Lead

With strong emphasis on innovation, customer support, and reliable products, Phoenix Equipment is recognized worldwide as a reputable composite manufacturing equipment supplier. Their catalog provides a range of composites applicators, gelcoat spray guns, and impregnation systems to meet the specific technical demands of modern manufacturing to either upgrade an existing production line or start a new fabrication process.

They base their solutions on an incredible depth of industry insight and engineering support, along with customization capacity. Solutions vary from compact systems suited for small shops to fully integrated automation lines for very large manufacturers. Phoenix Equipment ensures you have the tools necessary to deliver excellence.

Application Throughout Industries

With its versatile set of tools, Phoenix Equipment can be seen working in various fields:

Marine: For boats, yachts, and marine constructions, durable, weather resistant gelcoats and laminates are applied.

Aerospace: Lightweight and high strength components with resin infusion and impregnation with high accuracy.

Automotive: From composite body panels to structural supports and interiors.

Construction: Strong decorative composite panels for an architectural purpose.

Wind Energy: Manufacturing wind turbine blades with fair accuracy with fewer defects.

Final Thoughts:

With precision, speed, and performance being the parameters for success in this industry, investing in a good set of equipment is very essential. Phoenix Equipment's composites applicators, gelcoat spray guns, and impregnation systems have been designed with today's hardcore manufacturing realities in mind. Be it stronger boats, lighter cars, or more efficient wind turbines, these are the tools that provide the reliability and efficiency that will keep you ahead of the competition.

By choosing the right equipment partner, you are not just investing in tools but rather the future of your craftsmanship and business.

Note: IndiBlogHub features both user-submitted and editorial content. We do not verify third-party contributions. Read our Disclaimer and Privacy Policyfor details.